Left-right split traditional Chinese medicine pelleting equipment

A split-type, traditional Chinese medicine technology, which is applied in the direction of making medicines into special physical or taking forms, conveyors, mechanical conveyors, etc., which can solve the problems of reducing the use efficiency of the pill making unit, the uneven speed of the strips, and the pressure of the medicine. Uneven problems, to achieve the effect of ensuring stability, increasing space capacity, and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

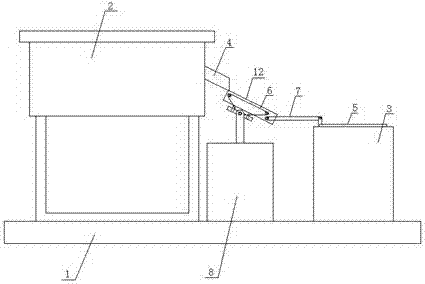

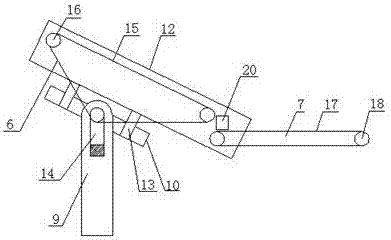

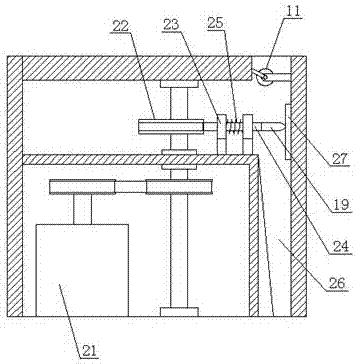

[0018] Such as Figure 1~3 As shown, a left and right split type traditional Chinese medicine pill making equipment of the present invention comprises a bottom plate 1 on which a medicine bar forming machine 2 and a pill making machine 3 are respectively arranged, and the side of the medicine bar forming machine 2 is provided with a medicine bar outlet 4 , the drug strip outlet 4 transports the cut medicine strip to the pill receiving platform 5 of the pill making machine 3 through the conveying device, the height of the medicine strip outlet 4 is higher than the height of the pill receiving platform 5 on the pill making machine 3, and the medicine strip Outlet 4 is set at a slant.

[0019] The conveying device of the present invention is a belt conveying device, and the belt conveying system includes a first belt conveying system 6 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com