Expandable Primary Mirror Mechanism with Large Aperture in Space

A technology with a large space and a large diameter, which is applied in the directions of instruments, installation, optics, etc., can solve the problems such as the difficulty of synchronous deployment of various components, complex and complicated structural settings, and easy shading, so as to avoid the problem of optical path occlusion, the source of driving force is simple, Unfold Motion Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

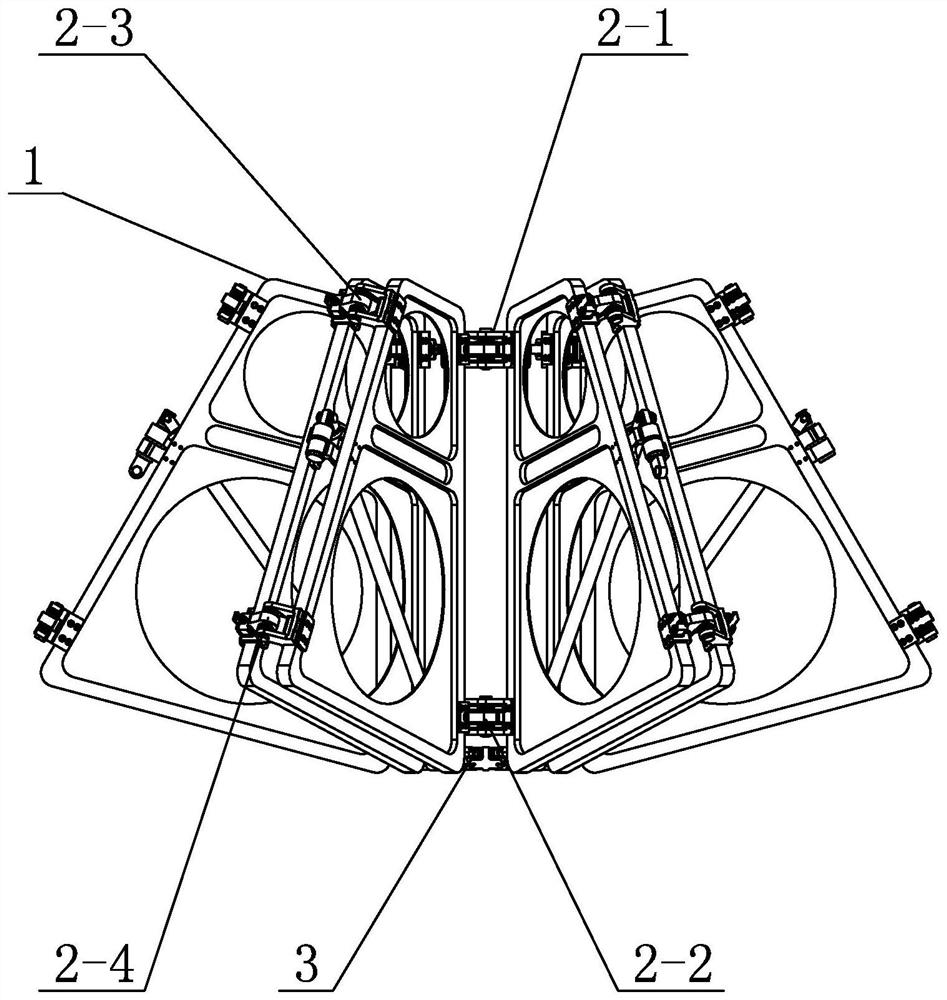

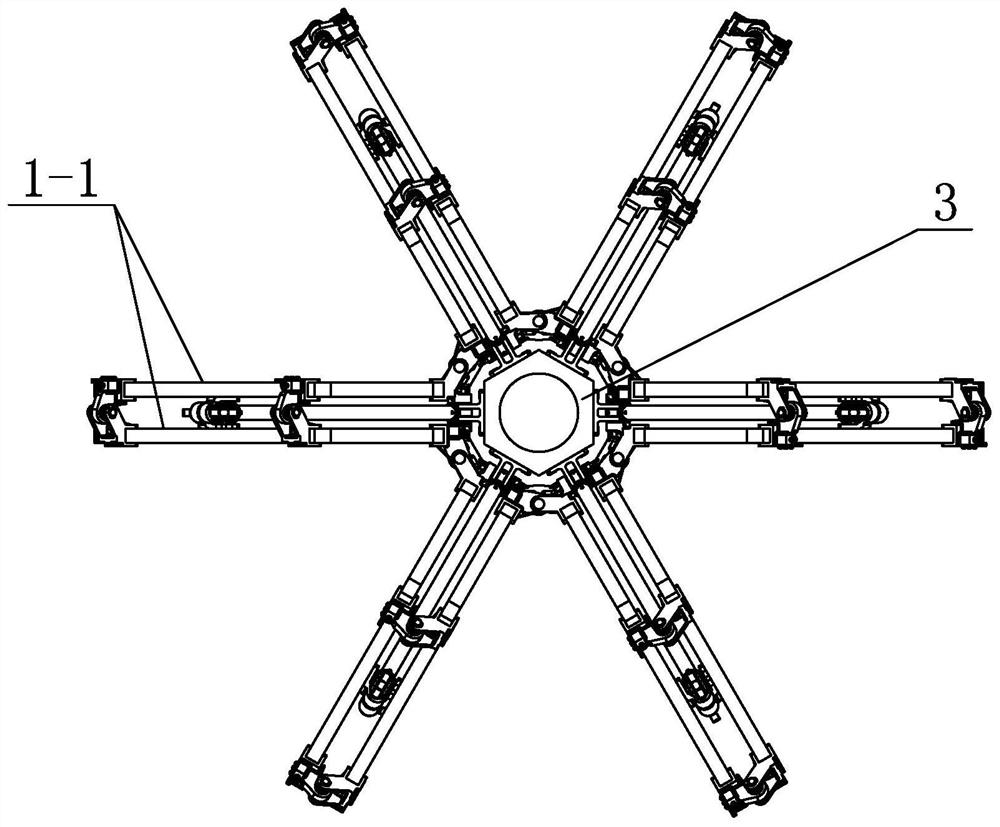

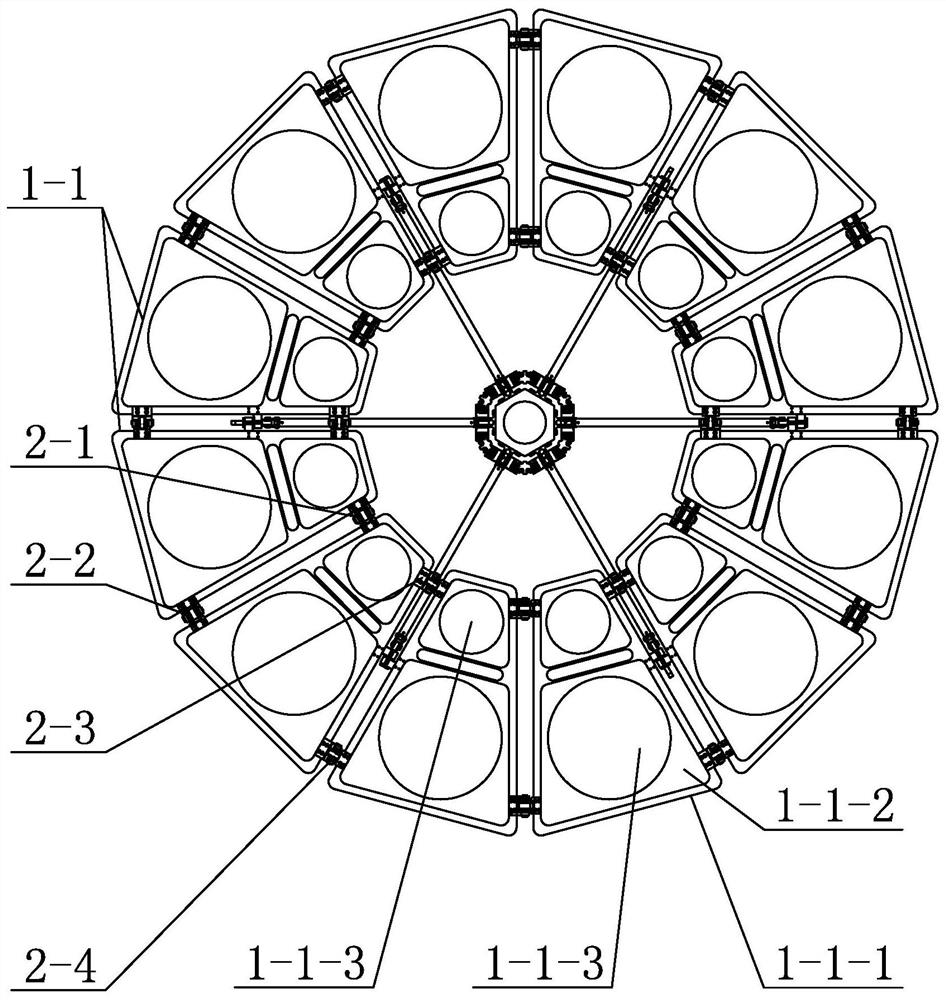

[0028] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 Describe this embodiment, which includes a linkage device 3, a deployment locking device and N groups of block mirror bodies 1, and the N groups of block mirror bodies 1 are uniformly arranged around the linkage device 3, and the deployment locking device The device includes N first hinges 2-1, N second hinges 2-2, N third hinges 2-3 and N fourth hinges 2-4, two groups of adjacent block mirrors The top of the body 1 is connected by a first hinge 2-1, and the bottoms of two adjacent groups of block mirror bodies 1 are connected by a second hinge 2-2, and each group of block mirror bodies 1 includes two Two sub-mirrors 1-1 are arranged side by side between the two sub-mirrors 1-1, the tops of the two sub-mirrors 1-1 are connected by a third hinge 2-3, and the bottoms of the two sub-mirrors 1-1 are connected by a fourth hinge Devic...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 1 to Figure 6Describe this embodiment, in this embodiment the structure of the first hinge 2-1, the structure of the second hinge 2-2, the structure of the third hinge 2-3 and the structure of the fourth hinge 2-4 are the same , the third hinge 2-3 includes a female hinge 2-3-1, a male hinge 2-3-2, a spring locking piece 2-3-3, a limiter 2-3-4, and a connecting shaft part 2- 3-5 and spring 2-3-6, the female hinge 2-3-1 and the male hinge 2-3-2 are hinged through the connecting shaft part 2-3-5, and the spring 2-3-6 is set on The connecting shaft part 2-3-5 is closely attached to the female hinge 2-3-1 and the male hinge 2-3-2, and the female hinge 2-3-1 is provided with a limiting member 2-3- 4. The limit piece 2-3-4 is provided with a spring locking piece 2-3-3, when the female hinge 2-3-1 and the male hinge 2-3-2 are made through the connecting shaft part 2-3-5 During the folding action, the female hinge 2-3-1 is...

specific Embodiment approach 3

[0035] Specific implementation mode three: combination figure 1 , figure 2 with image 3 Describe this embodiment, the sub-mirror 1-1 in this embodiment includes a mirror frame 1-1-1, a lens adjustment device 1-1-2 and several lenses 1-1-3, and the mirror frame 1-1- 1 is provided with a lens adjusting device 1-1-2, and several lenses 1-1-3 are arranged on the lens adjusting device 1-1-2.

[0036] In this embodiment, the mirror frame 1-1-1 plays the role of supporting the lens adjusting device 1-1-2 and several lenses 1-1-3. The lens adjusting device 1-1-2 is a fine-tuning device for adjusting the rotation angle of the lens 1-1-3, specifically an ultrasonic motor or a driver made of piezoelectric ceramics. The setting of the lens adjusting device 1-1-2 enables several lenses 1-1-3 to be adjusted in time and effectively after the position of the segmented mirror body 1 is slightly changed from the folding action to the unfolding action, so as to ensure that the space main mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com