A space-based retractable telescopic binary optical camera mechanism

A binary optics, sleeve-type technology, applied in optics, cameras, focusing devices of cameras, etc., can solve the problems of large mass, easy blocking of shooting light, difficulty in repeated expansion and contraction, etc., and achieves light weight and simple expansion movement. , the effect of easy installation and function expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

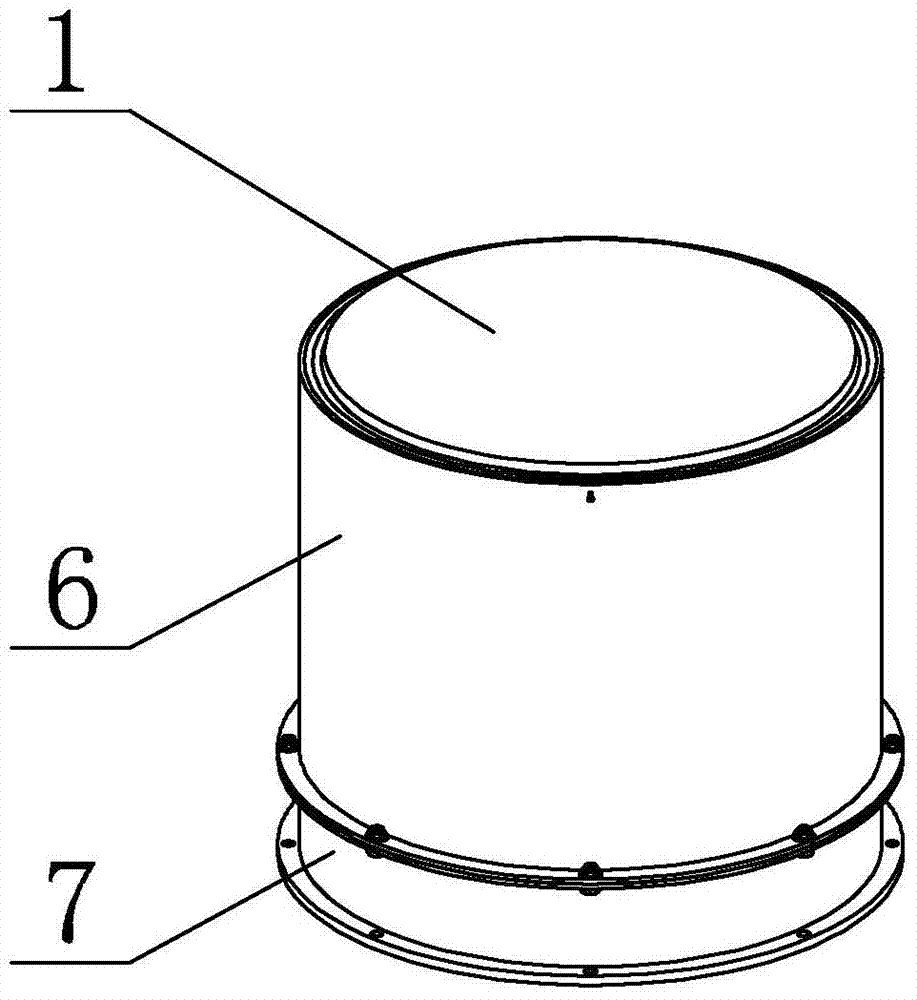

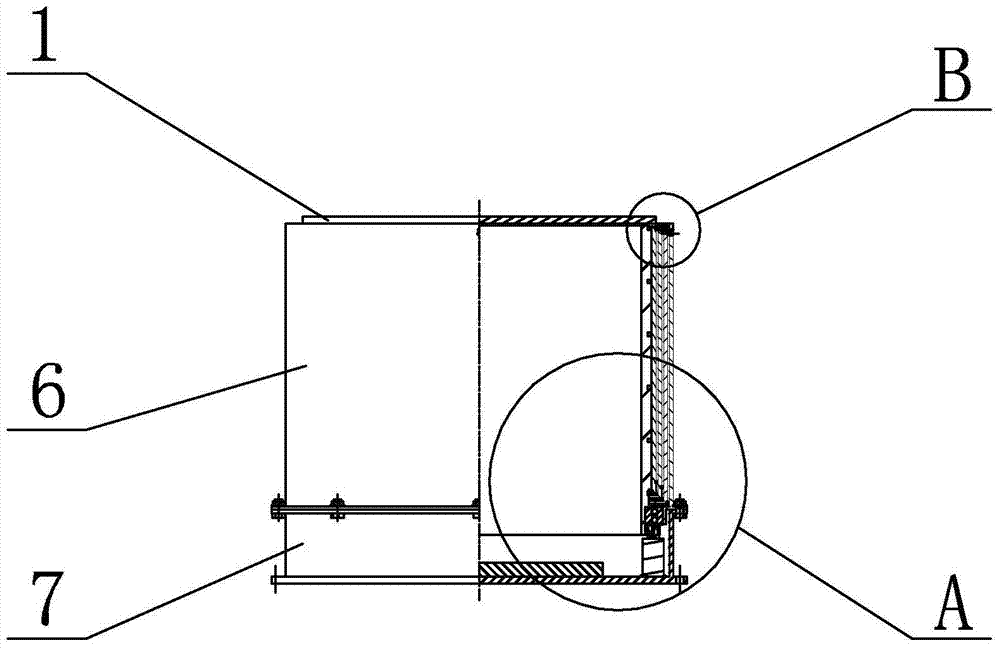

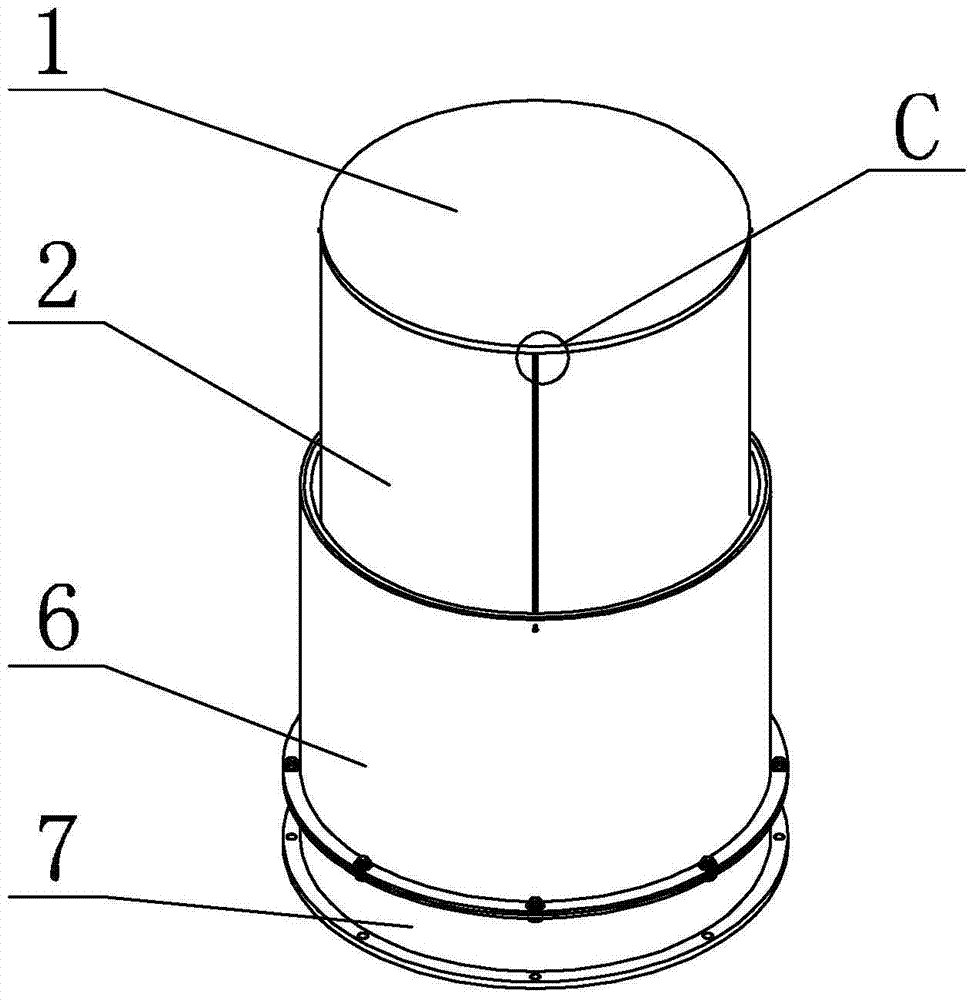

[0035] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 with Figure 15Describe this embodiment, in this embodiment it includes camera main mirror 1, first telescopic cylinder 2, second telescopic cylinder 4, at least one third telescopic cylinder 5, fixed cylinder 6, drive cylinder 8, base 7, bearing support system 9. Gear transmission mechanism 10, stepper motor 11, bottom receiving mirror 12 and locking mechanism 3, the first telescopic cylinder 2, the second telescopic cylinder 4, at least one third telescopic cylinder 5 and the fixed cylinder 6 from above From the bottom to the bottom, the camera lens barrel is formed by connecting with the locking mechanism 3. The outer diameter of the first telescopic tube 2 is smaller than the outer diameter of the second telescopic tube 4, and the outer diameter o...

specific Embodiment approach 2

[0040] Specific implementation mode two: combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 16 Describe this embodiment, the first telescopic tube 2 in this embodiment includes a first tube body 2-1, a plurality of first guide wheels 2-2 and a plurality of first guide rails 2-4, the first tube body 2-1 A plurality of first guide wheels 2-2 are evenly distributed along the circumferential direction of the first cylinder body 2-1 on the inner wall of the bottom of the first cylinder body 2-1. A plurality of first taper pin holes 2-3 are evenly processed in the circumferential direction of the first barrel body 2-1, and a plurality of first taper pin holes 2-3 are evenly arranged on the outer wall of the first barrel body 2-1 along the axial direction of the first barrel body 2-1. Rails 2-4.

[0041] In this embodiment, multiple first guide rails 2-4 all move synchronously, and the optimal numb...

specific Embodiment approach 3

[0043] Specific implementation mode three: combination Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 10 Describe this embodiment. In this embodiment, the locking mechanism 3 includes multiple sets of first locking devices 3-1, and the second telescopic tube 4 includes a second tube body 4-1 and multiple second guide wheels 4. -2 and a plurality of second guide rails 4-4, the inner wall of the bottom of the second cylinder body 4-1 is evenly distributed with a plurality of second guide wheels 4-2 along the circumferential direction of the second cylinder body 4-1, so A plurality of second taper pin holes 4-3 are evenly processed on the outer wall of the bottom of the second cylinder body 4-1 along the circumferential direction of the second cylinder body 4-1, The axial direction of the second cylinder body 4-1 is evenly provided with a plurality of second guide rails 4-4, and the upper end of each second guide rail 4-4 is correspondingly provided with a set of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com