Telescopic truss type binary optical space camera and on-orbit work method thereof

A binary optics and working method technology, applied in optics, optical components, installation, etc., can solve the problems of large mass, difficulty in repeated folding, complex structure, etc., and achieve the effect of light weight, easy transportation, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

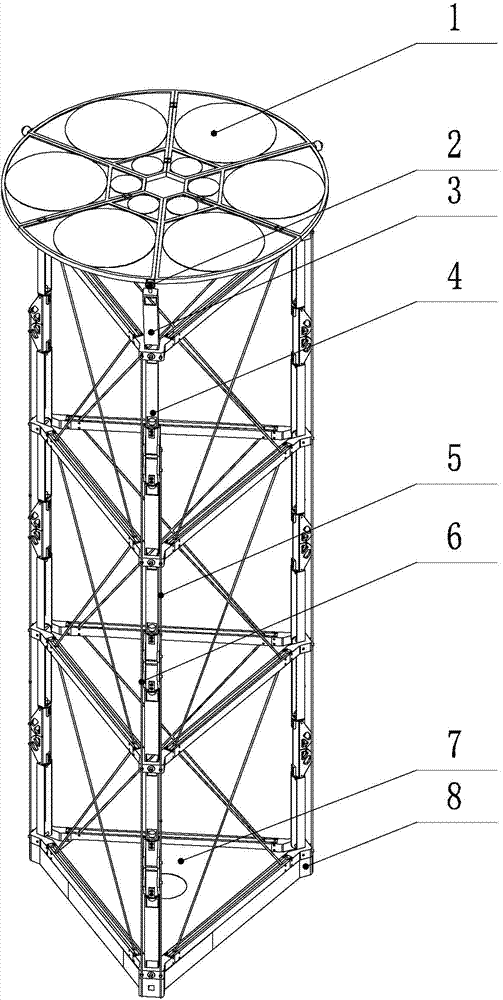

[0031] Specific implementation mode one: the following combination figure 1 , Figure 5 and Image 6 This embodiment is described. The space-scalable truss-type binary optical camera described in this embodiment includes a block-type expandable optical primary mirror 1, a spherical hinge 2 and a support arm 3;

[0032] The segmented expandable optical main mirror 1 includes 2N segmented sub-mirrors, wherein: N is a positive integer, and N≥3; each segmented sub-mirror includes a sub-block support frame 9, a trimmer 10, and a lens support plate 11 And the lens 14, the lens 14 is installed on the lens support plate 11, the lens support plate 11 is embedded into the sub-block support frame 9 through the trimmer 10; a spring hinge driver 12 and a lock are installed between two adjacent sub-block sub-mirrors 13;

[0033] The support arm 3 includes a plurality of structural foldable units 4, pull cables 5, speed control cables 6, base 7 and drive controller 8; the structural folda...

specific Embodiment approach 2

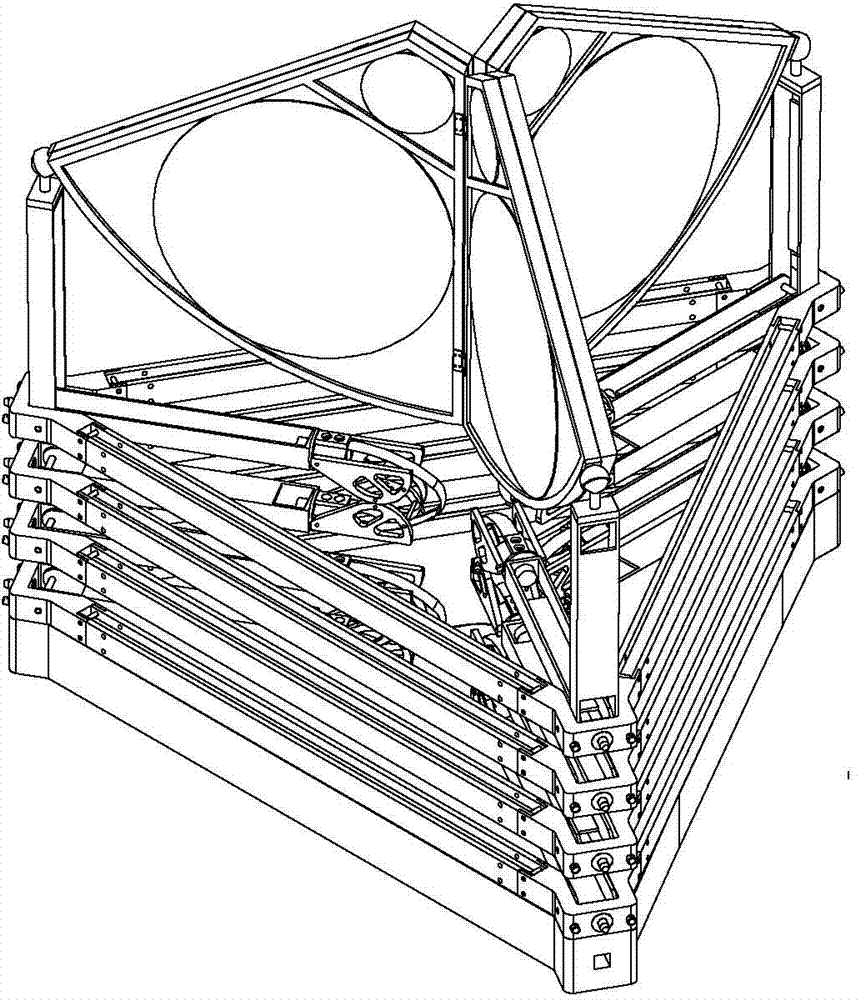

[0038] Specific implementation mode two: the following combination Figure 5 This embodiment will be described. This embodiment will further describe the first embodiment. The two triangular frames 15 are also equipped with six stay cables 19 .

[0039] In this embodiment, the six stay cables 19 are used to improve the rigidity and stability of the frame-type foldable unit 4 .

specific Embodiment approach 3

[0040] Specific implementation mode three: the following combination Figure 1-Figure 4 Describe this embodiment, the on-orbit working method based on the space-scalable truss-type binary optical camera described in this embodiment, its on-orbit working method includes four working modes, namely: launching and retracting mode, support arm unfolding mode, in-orbit On-orbit running mode and on-orbit folding mode;

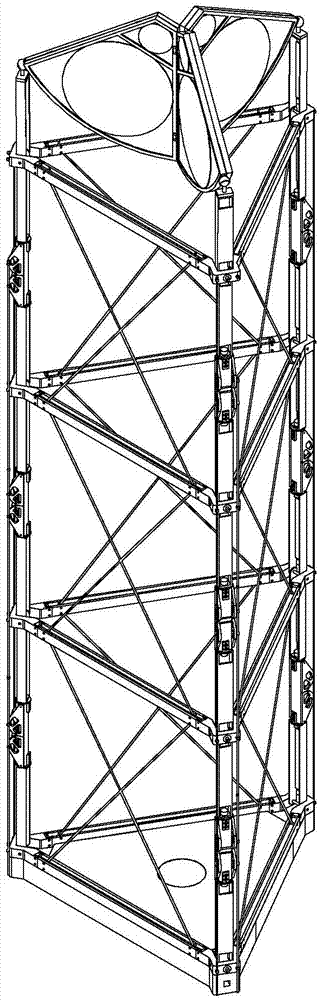

[0041] Launching folded mode: In the launching state, the support arm 3 and the segmented expandable optical main mirror 1 are both in the folded mode, see image 3 shown;

[0042] Support arm deployment mode: After entering the orbit, the drive controller 8 drives the motor to rotate forward, the cable 5 and the speed control cable 6 are released, and the support arm 3 is expanded under the drive of the spring hinge 17. After the expansion is in place, it is locked and stiffened, and the folded state The block-type expandable optical primary mirror 1 is sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com