Rubber tire roller

一种橡胶轮胎、压路机的技术,应用在橡胶轮胎压路机领域,能够解决大施工空间、形成隧道复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

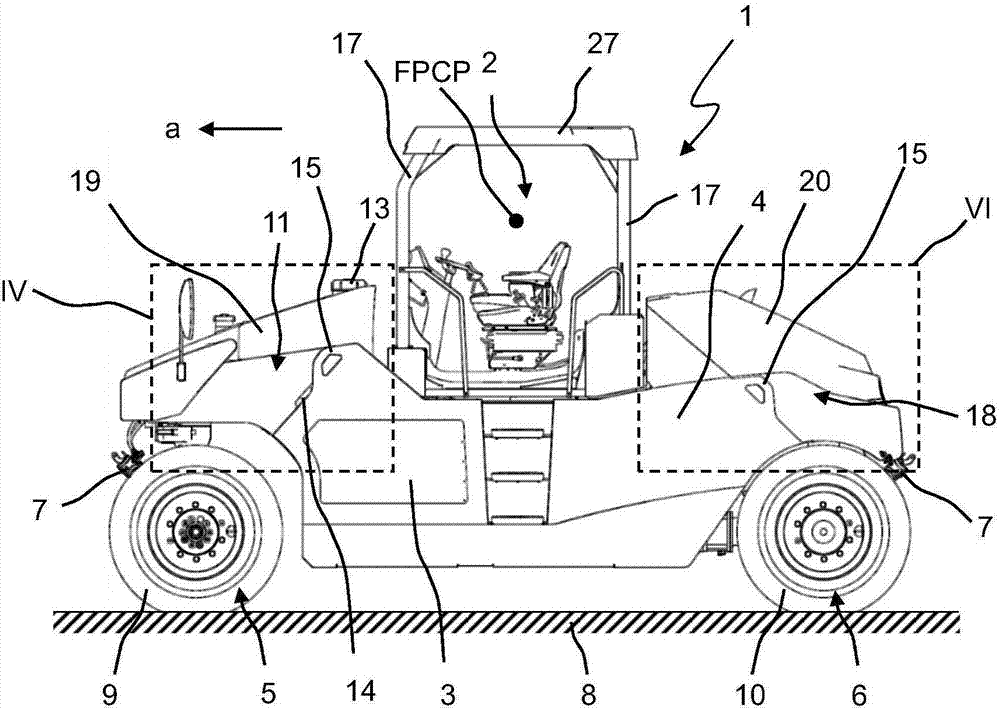

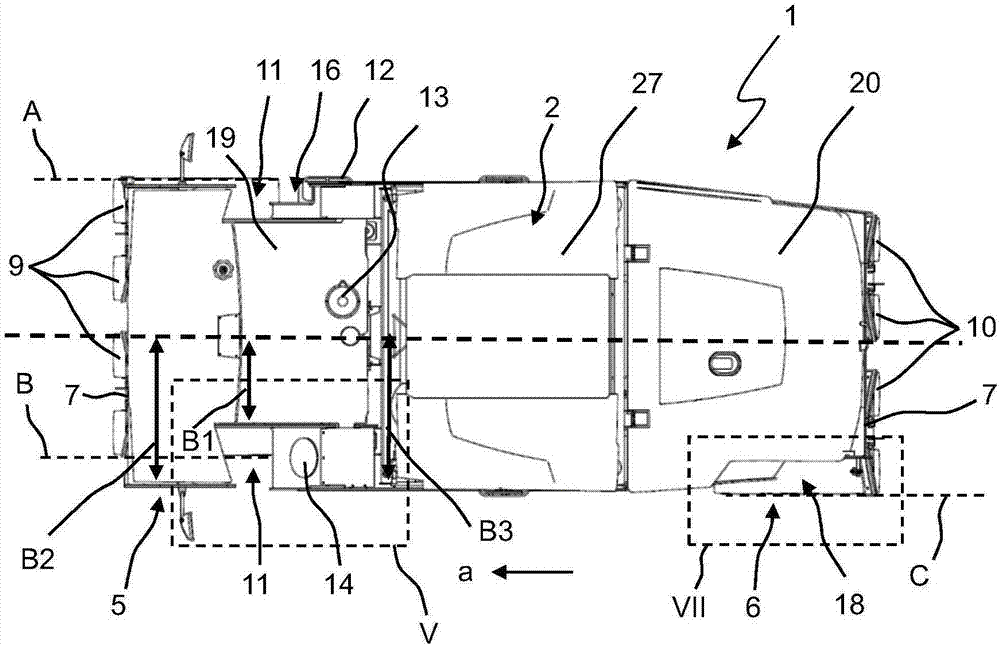

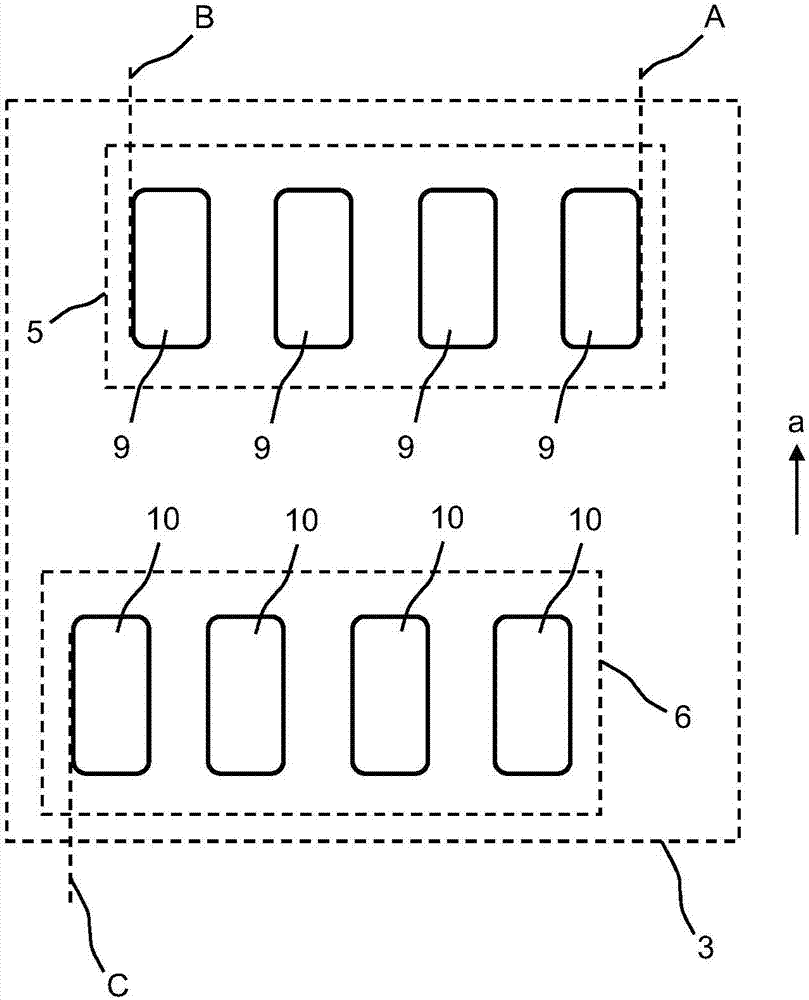

[0036] Components that are identical or have the same function are identified with the same reference numerals. Repeated components are not necessarily indicated individually in each figure.

[0037] Figures 1 to 11 A preferred illustrative embodiment of a rubber-tyred road roller 1 according to the invention is shown. Generally, a rubber tire road roller 1 includes an operating platform 2 and a frame 3 . During operation, the rubber-tyred road roller 1 is driven by a power source 4, usually a diesel engine, and by means of a driven front chassis 5 and a rear chassis 6 over the ground 8 alternately in or against the direction of advancement a move. The chassis 5 and 6 each comprise four individual wheels arranged next to each other. Ideally, a driver's seat displaceable across the width of the platform is arranged on the console 2 . exist figure 1 In , the approximate position of the FPCP according to DINISO 5006:2017 is shown for illustrative purposes.

[0038] In ord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com