Automobile headlight cushioning package

A technology of automotive headlights and cushioning packaging, applied in the packaging field, can solve the problems of non-reusable, easy to deform, and pollute the environment, and achieve the effects of easy disassembly, high compressive strength, and safe storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

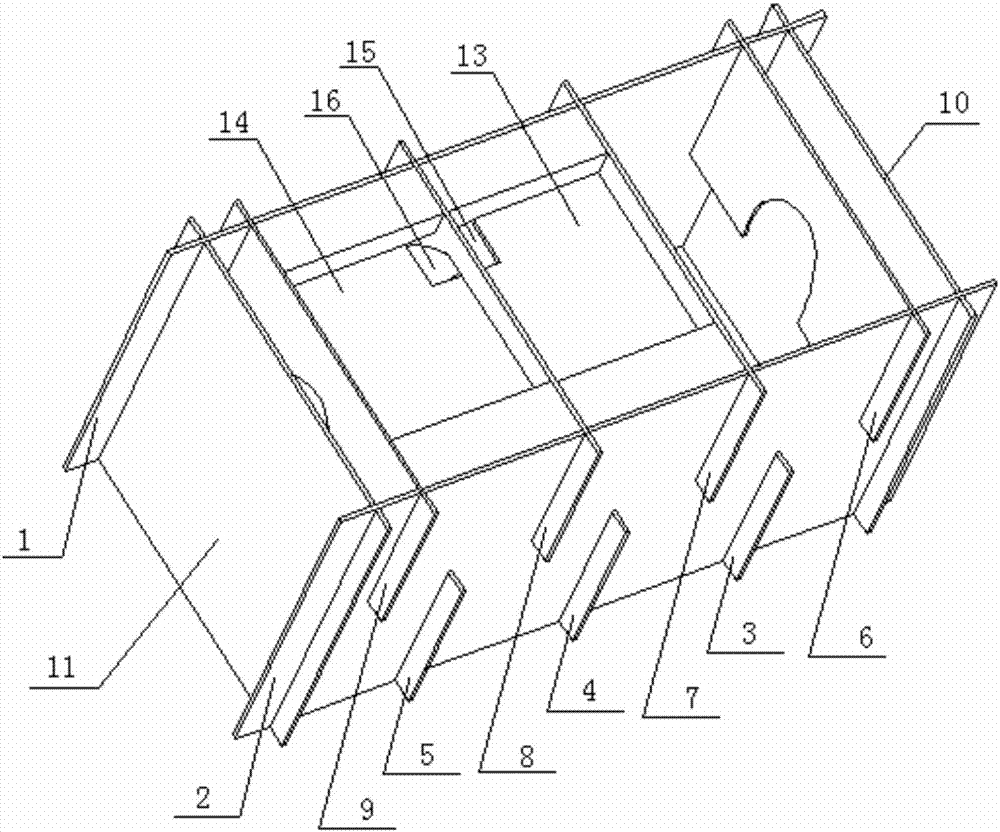

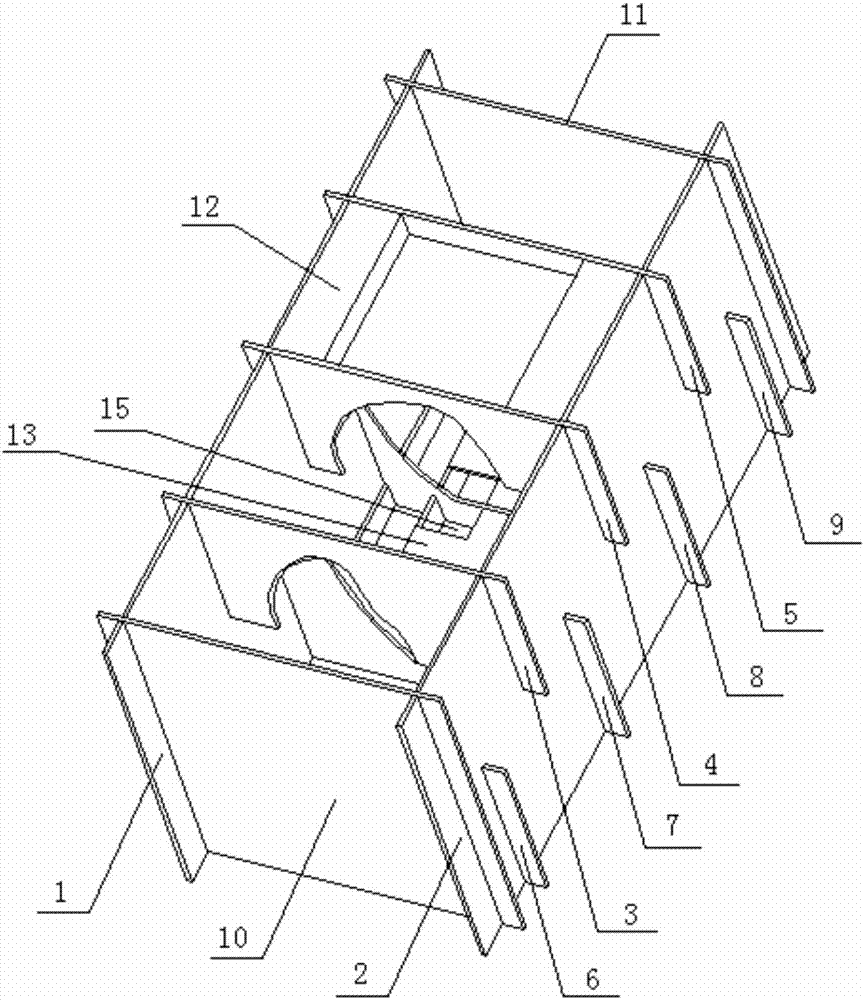

[0032] The overall schematic diagram of the internal main buffer structure of the automobile headlight buffer package of the present invention is as follows: figure 1 and figure 2 As shown, it includes supporting board one 1, supporting board two 2, inner board one 3, inner board two 4, inner board three 5, inner board four 6, inner board five 7, inner board six 8, Inner board seven 9, end board one 10, end board two 11, buffer board one 12, buffer board two 13, buffer board three 14, safety hole one 15 and safety hole two 16.

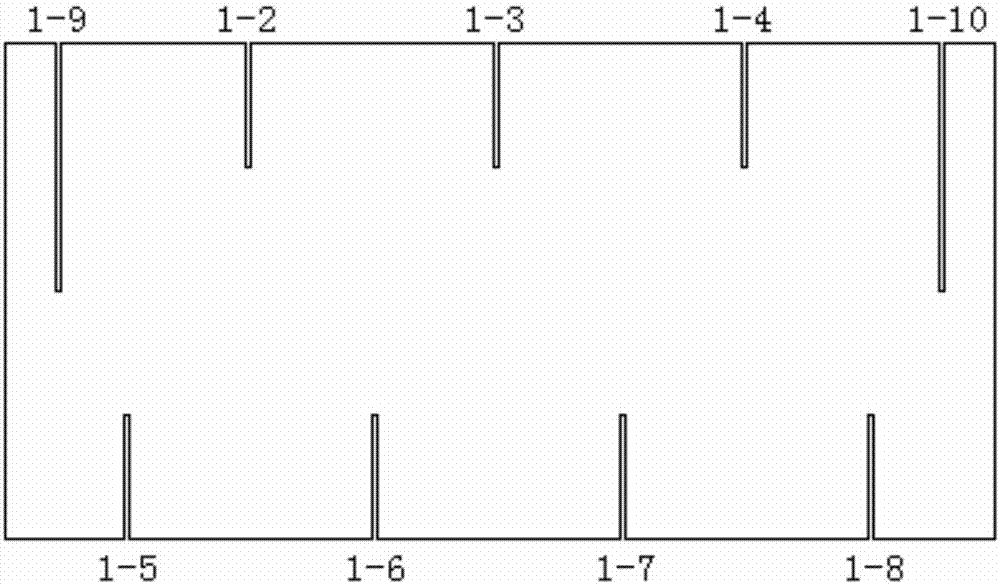

[0033] The schematic diagram of the support plate one 1 and the support plate two 2 is as image 3 As shown; there are 5 equidistant slots on one side of the support plate: end slot one 1-9, slot two 1-2, slot three 1-3, slot four 1-4, end slot two 1-10, the distance between its end slot one 1-9, end slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com