Device and method for monitoring stress transfer length of pre-tensioned prestressing rib based on optical fiber sensing

A technology of prestressed tendons and monitoring devices, applied in the direction of measuring devices, optical devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0089] According to the second embodiment provided by the present invention, a method for monitoring the stress transfer length of pretensioned prestressed tendons based on optical fiber sensing is provided.

[0090] A method for monitoring the stress transfer length of pretensioned prestressed tendons based on optical fiber sensing, the method comprising the following steps:

[0091] 1) According to the size of the concrete 6 to be poured and the expected prestressed size of the prestressed tendons 1, determine the number of metal rings 3, the gap between the metal rings 3 and the prestressed tendons 1, and determine the length of the fixed support 2;

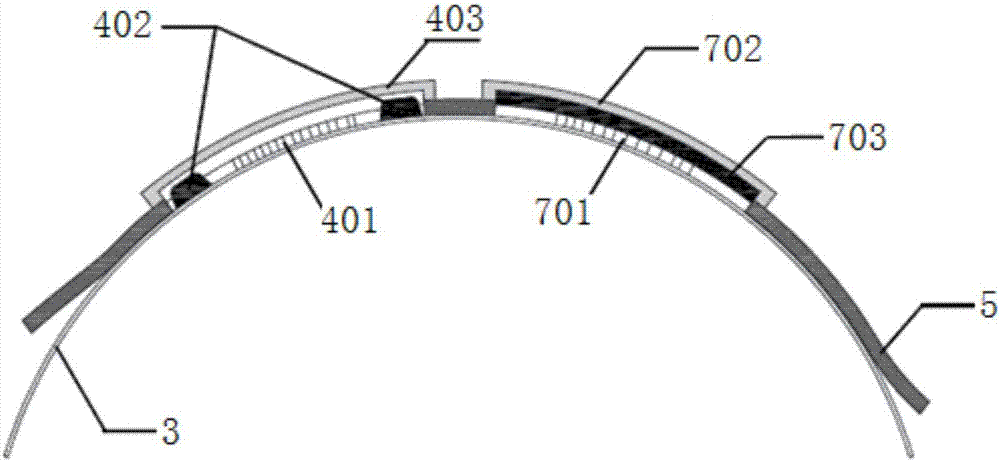

[0092] 2) Fix the metal ring piece 3 on the fixed bracket 2, set the detection grating 4 and the temperature compensation grating 7 on the metal ring piece 3, use the transmission fiber 5 to connect the detection grating 4 and the temperature compensation grating 7 in series, and the transmission fiber 5 The other end is conne...

Embodiment 1

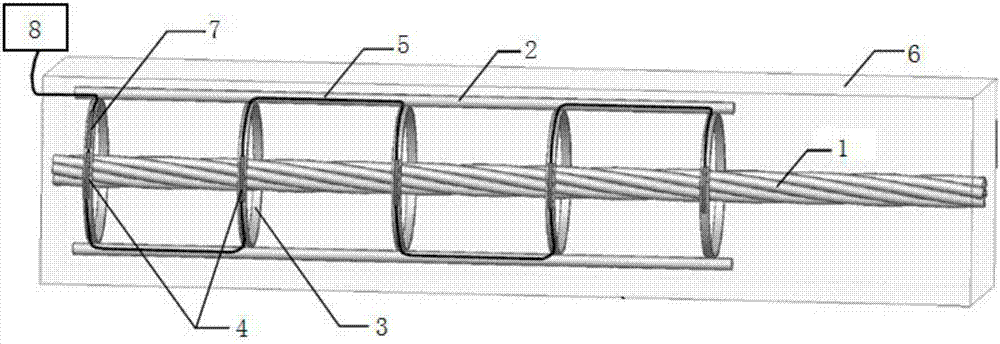

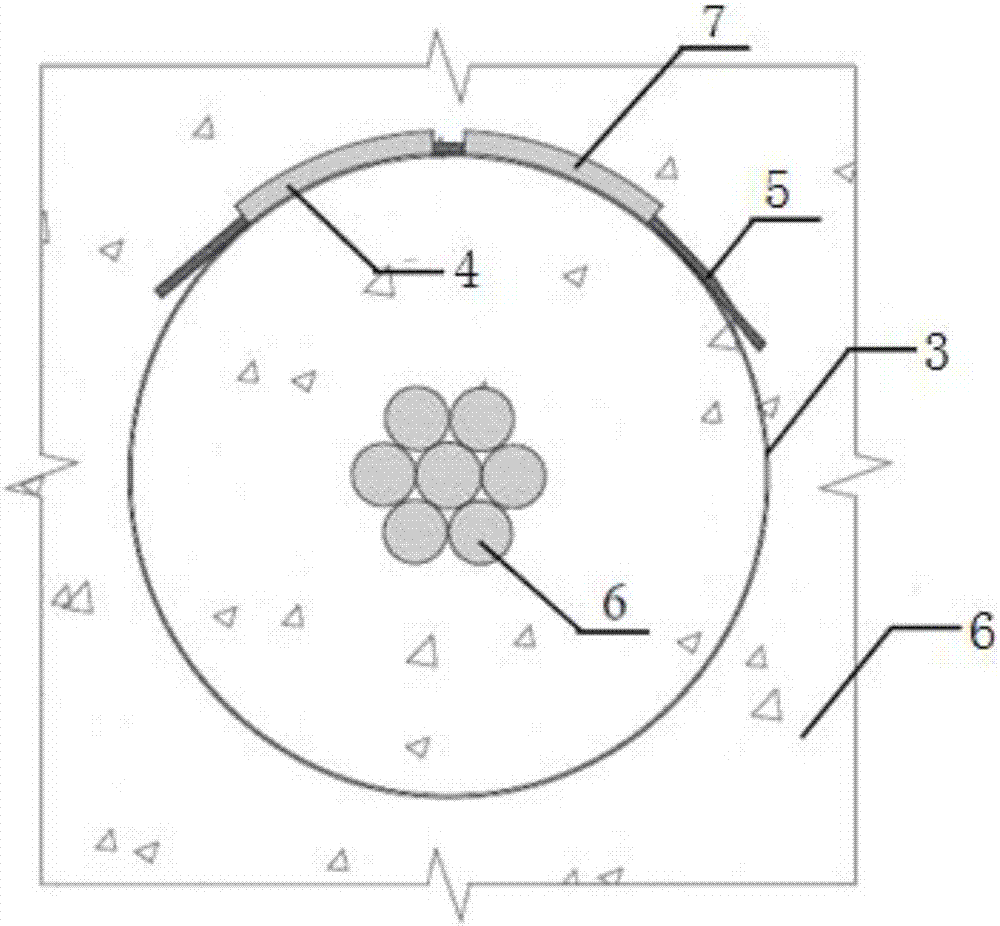

[0106] Such as Figure 1-4 As shown, a pre-tensioned prestressed tendon stress transmission length monitoring device based on optical fiber sensing, the monitoring device includes 2 fixed brackets 2, 5 metal rings 3, detection grating 4, transmission optical fiber 5. The prestressed tendon 1, the fixing bracket 2, the metal ring piece 3 and the detection grating 4 are all arranged in the concrete 6. A fixed bracket 2 is provided on one side or around the prestressed tendon 1 . The metal ring piece 3 is arranged on the fixing bracket 2 . The prestressed tendon 1 passes through the middle of the metal ring sheet 3, and there is a gap between the metal ring sheet 3 and the prestressed tendon 1. Each metal ring piece 3 is provided with a detection grating 4 . One end of the transmission fiber 5 is connected to the detection grating 4 , and the other end of the transmission fiber 5 extends out of the concrete 6 . The monitoring device also includes a temperature compensation gr...

Embodiment 2

[0110] Repeat Example 1, except that the monitoring device also includes a monitoring control analysis system 8 . One end of the transmission optical fiber 5 protruding from the concrete 6 is connected to a monitoring control analysis system 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com