Automatic socket mechanism of packaging machine

A packaging machine and driving mechanism technology, applied in the direction of packaging, transportation and packaging, packaging/bundling of articles, etc., can solve the problems of low packaging efficiency, high labor intensity, etc., to facilitate palletizing and transportation, reduce labor intensity, and improve labor efficiency. productivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

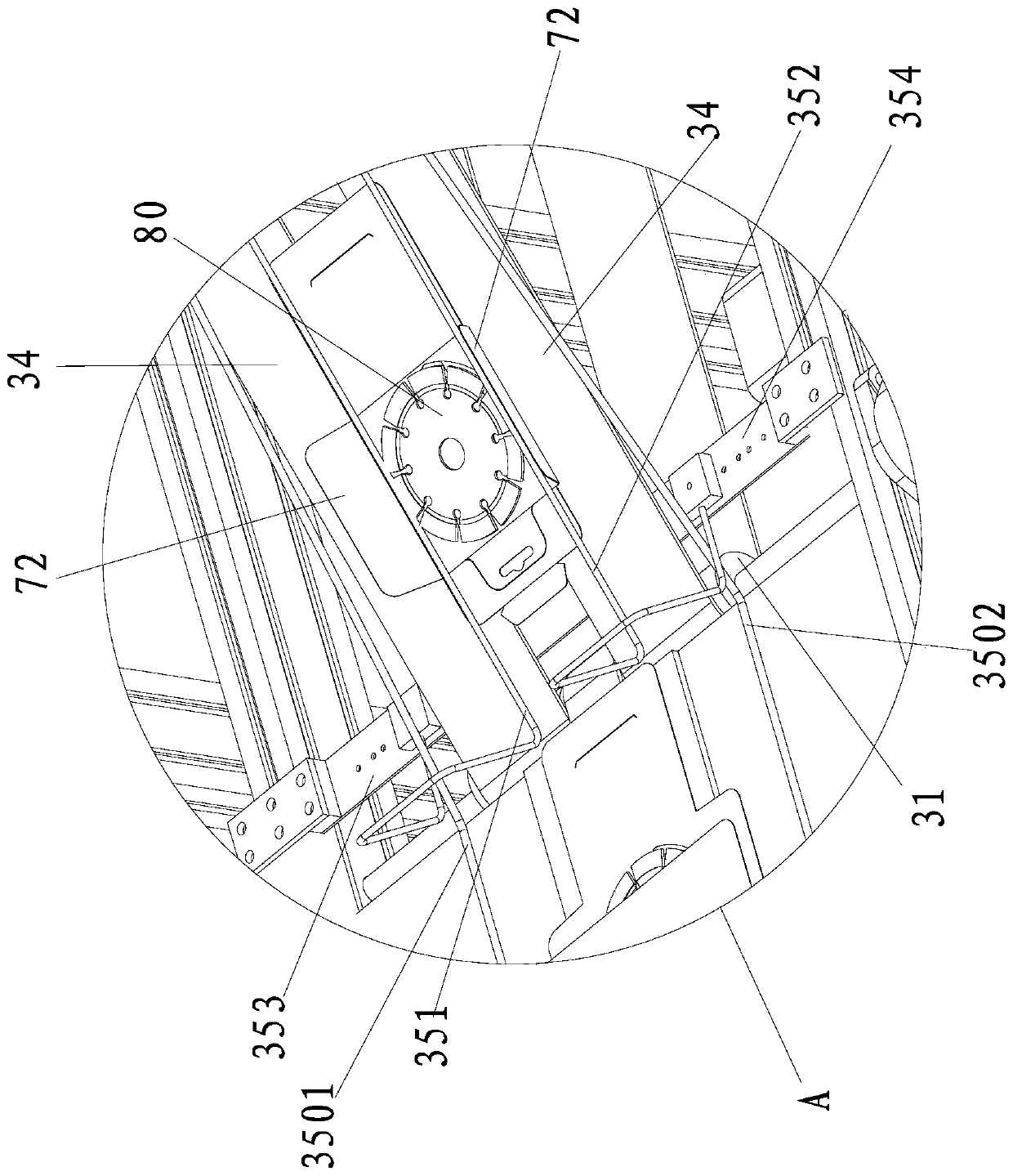

[0071] refer to Figure 1 to Figure 10 , in an embodiment of the present invention, the workpiece is a saw blade, and the packaging sheet 70 includes a support body 71 for supporting the saw blade, and the periphery of the support body 71 forms two side wings 72, a head wing 74 and an tail wing 73, and the head wing 74 An insert 741 is formed on the top, and a bayonet 731 matched with the insert 741 is formed on the tail wing 73. In order to facilitate the hanging of the packaged saw blade, a hanging ear 75 is provided on the head wing 74, and a hanging ear 75 is formed on the hanging ear 75. Hole 76.

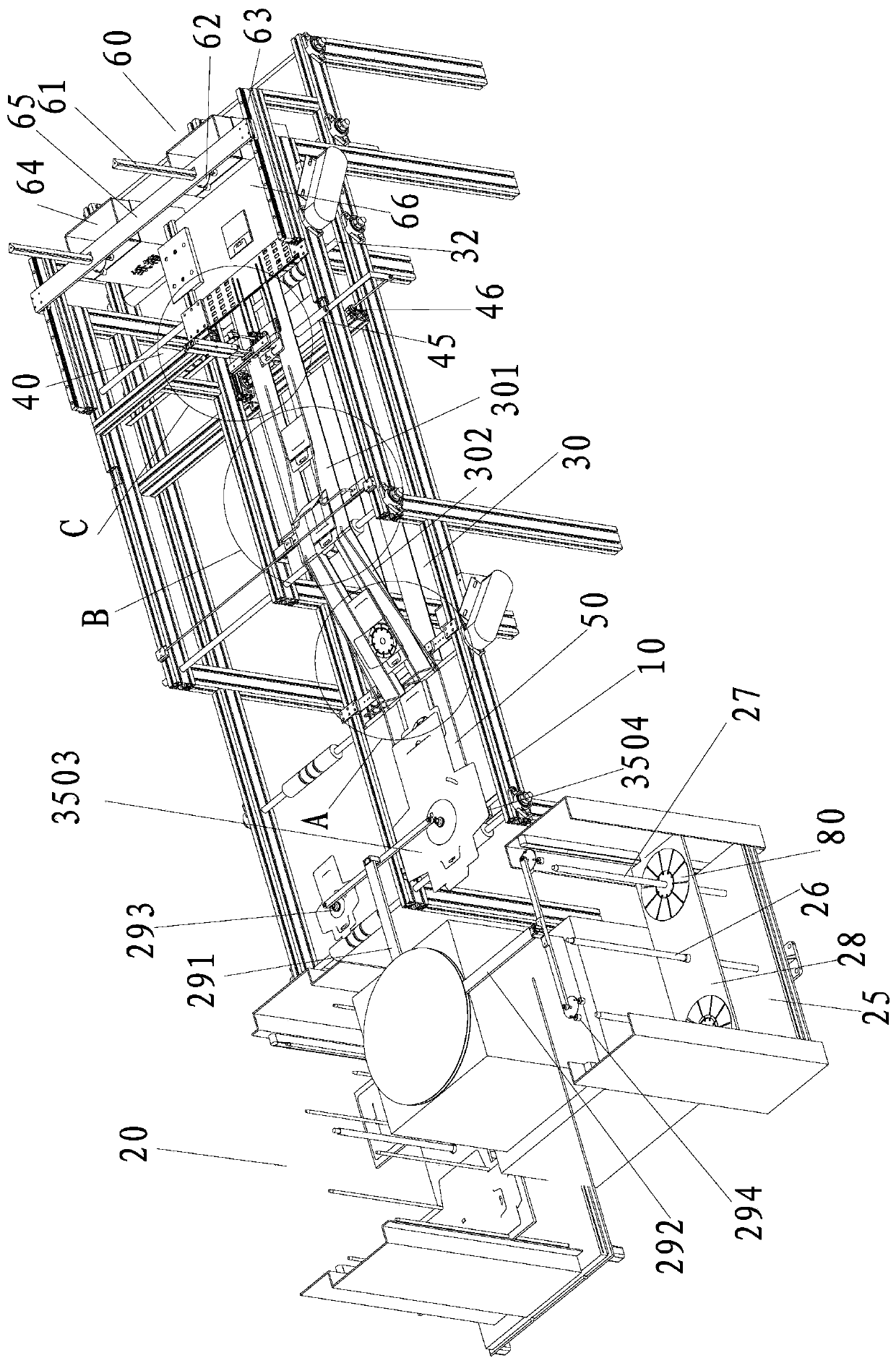

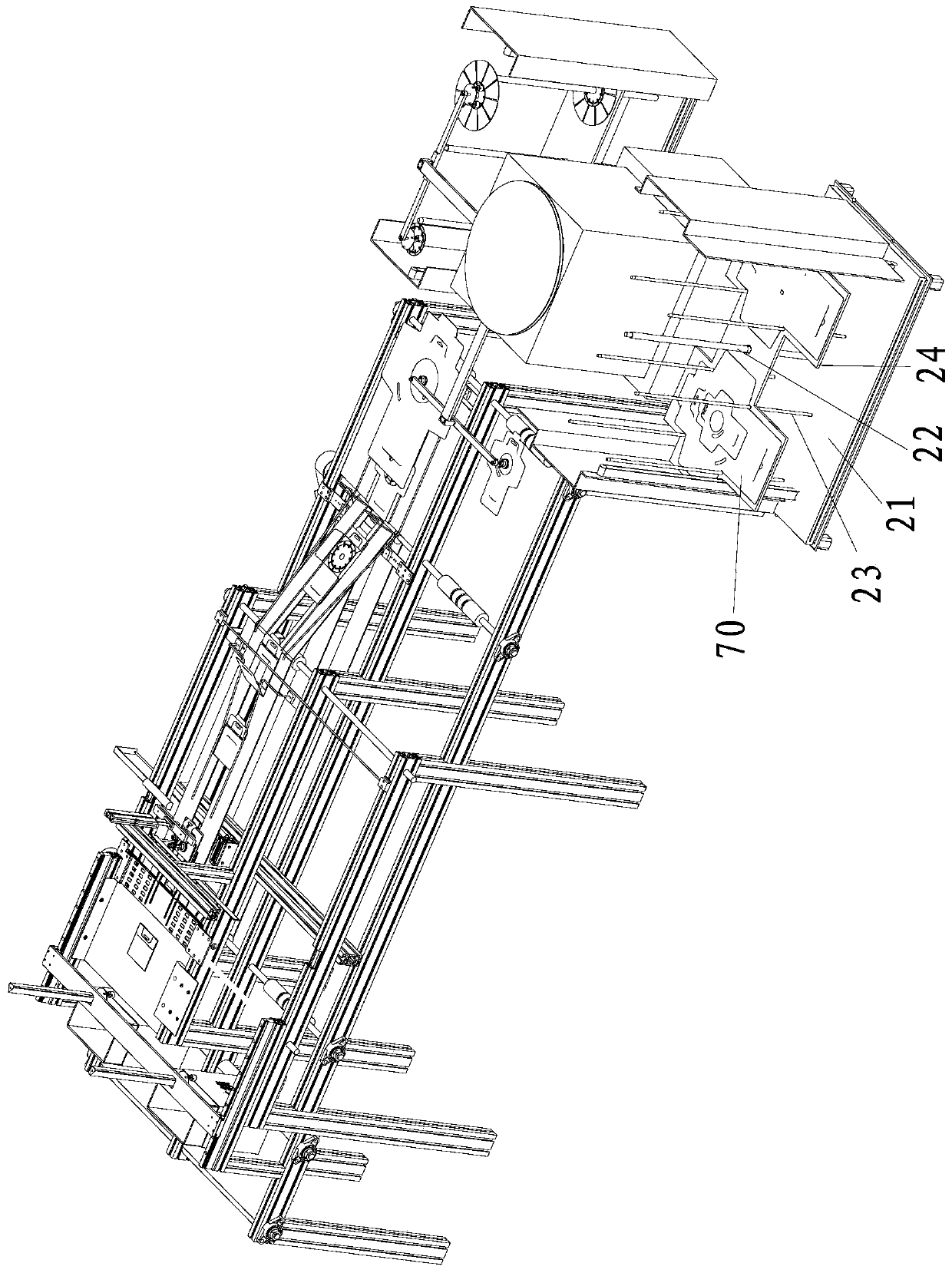

[0072]The automatic packaging machine of the present invention includes a frame 10, a feeding mechanism 20 for supplying the expanded packaging sheet 70 and a supply workpiece 80, a conveying device 30 for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com