Washing machine and laundry basket assembly thereof

A washing machine and component technology, applied in the field of washing machines, can solve problems such as unsatisfactory performance of washing machines, wear and tear of precious clothes, and entanglement of clothes and transmission shafts, and achieve the effects of improving user experience, good washing effect, and simple structure and principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

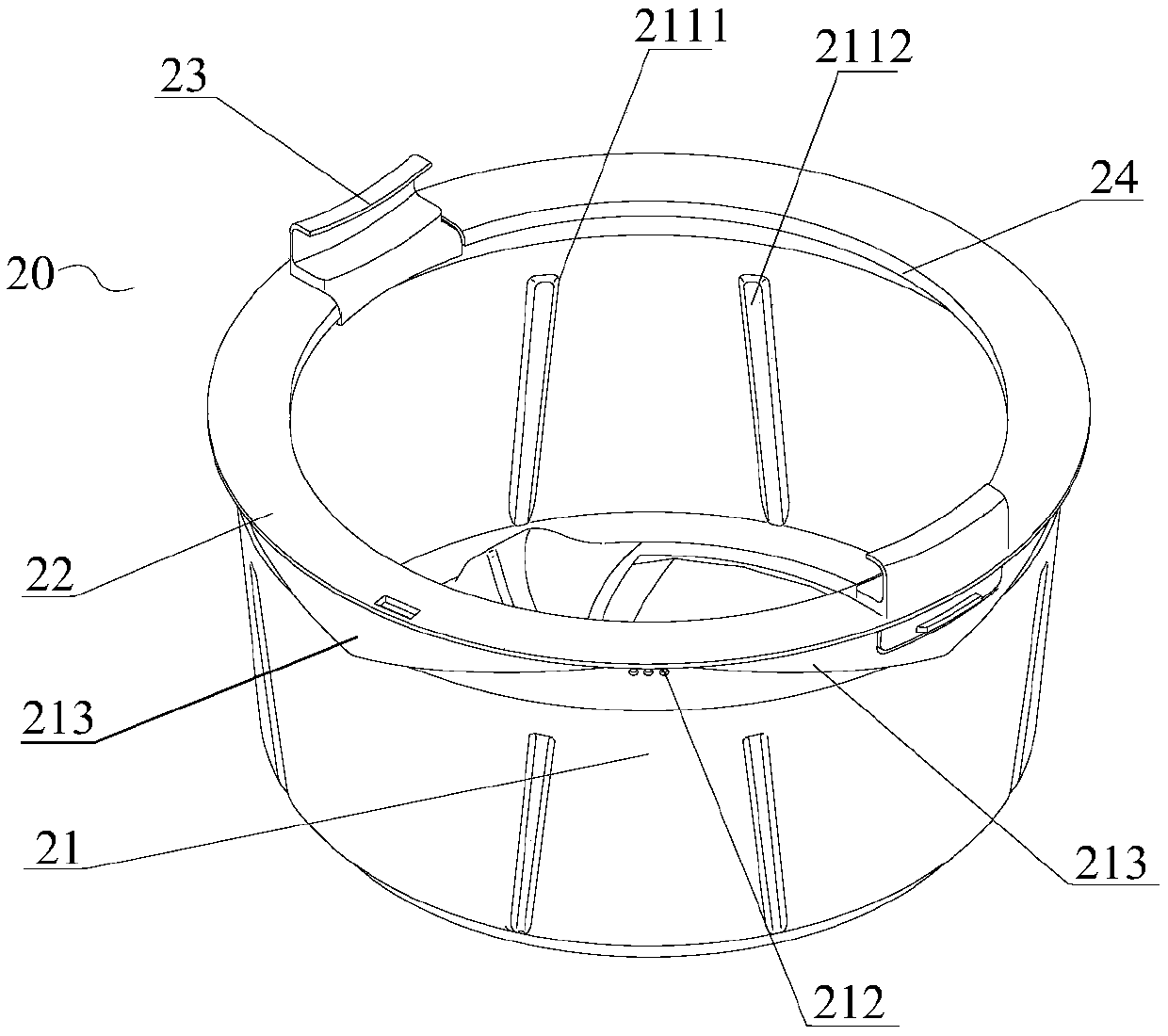

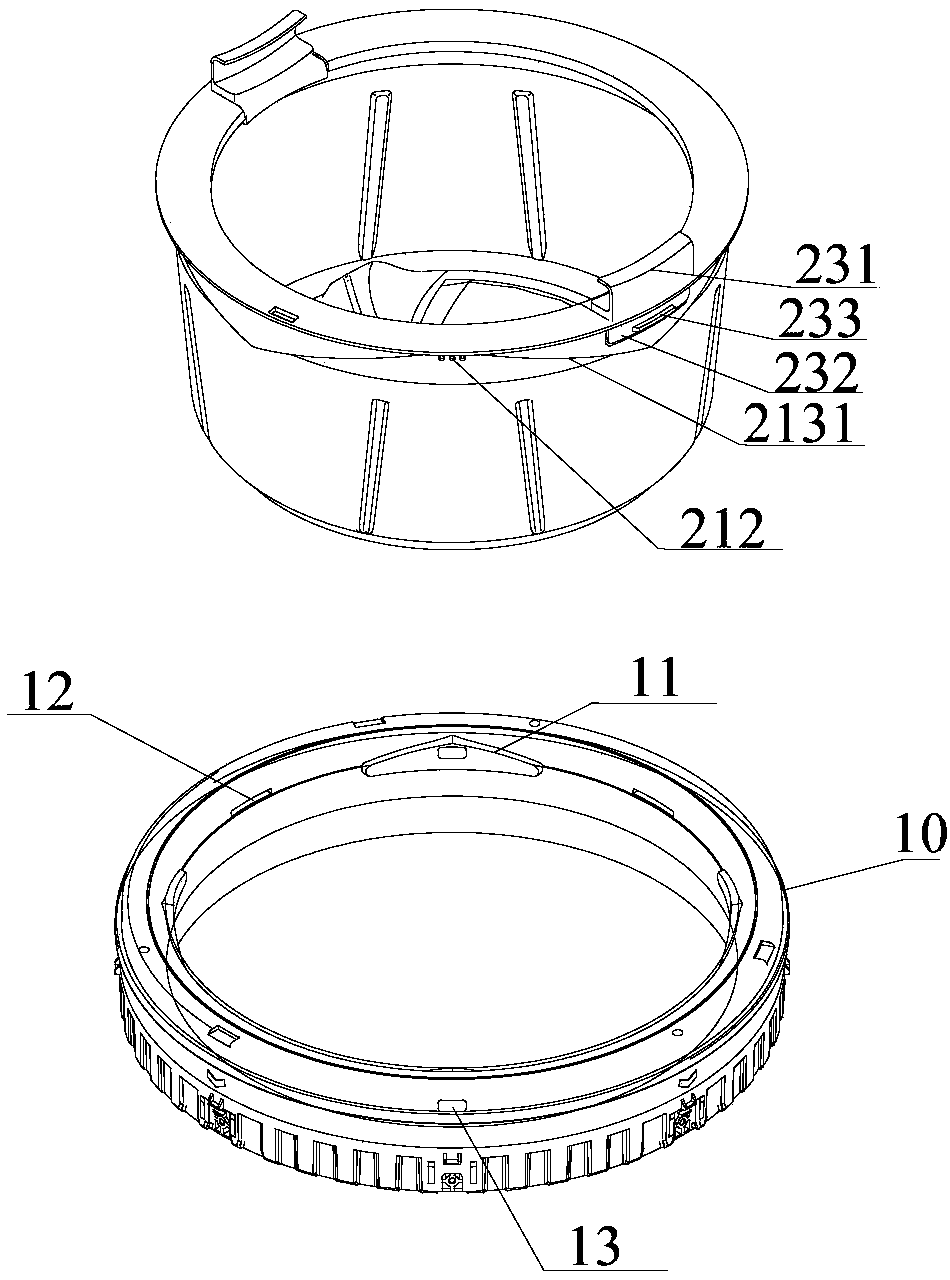

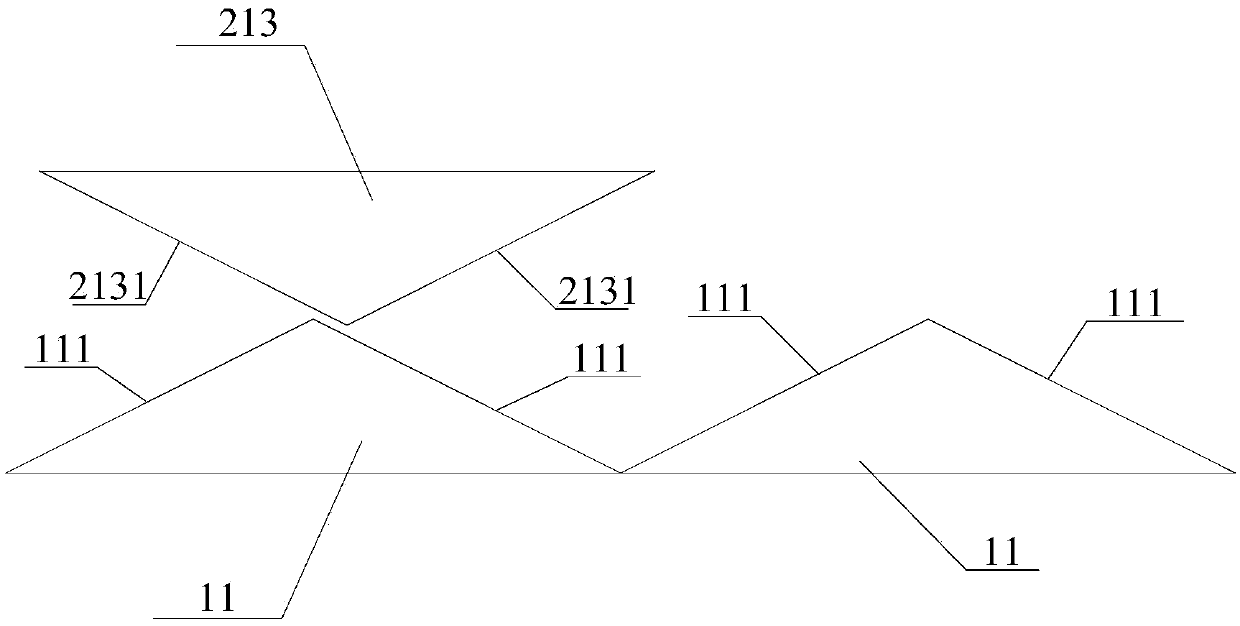

[0064] The inner wall of the balance ring 10 is provided with a first guide plate 11, and the first guide plate 11 is formed with two first guide slopes 111 arranged at intervals, such as image 3 with Figure 4 As shown; the outer wall of the laundry basket 20 is provided with a second guide plate 213, and the second guide plate 213 is formed with two second guide slopes 2131 arranged at intervals, as image 3 with Figure 4 As shown, the two second guiding slopes 2131 correspond to the two first guiding slopes 111 one by one.

[0065] The first guide plate 11 is set on the inner side wall of the balance ring 10, correspondingly, the second guide plate 213 is set on the outer side wall of the laundry basket 20, by rationally designing the shape of the first guide plate 11 and the second guide plate 213 that is The first guide slope 111 and the second guide slope 2131 can be formed. The structure and principle are relatively simple and easy to implement. At the same time, th...

Embodiment 2

[0083] The difference with Embodiment 1 is: on the basis of Embodiment 1, further, the lower part of the buckle 23 is provided with a torsion spring, and the torsion spring cooperates with the buckle 23 and the balance ring 10, and its elastic deformation 233 gradually increases in the process of getting out of the card slot 12.

[0084] A torsion spring is arranged at the bottom of the buckle 23, and the torsion spring cooperates with the buckle 23 and the balance ring 10, and its elastic deformation increases gradually when the buckle 233 escapes from the draw-in groove 12. After the assembly is completed, the torsion spring What is applied to the buckle 23 is to prevent the protrusion 233 from slipping out of the slot 12, thus effectively improving the fixing reliability of the laundry basket 20; at the same time, during the assembly of the laundry basket 20, when the laundry basket 20 slides to the preset When it is in the installation position, the torsion spring will dri...

Embodiment 3

[0087] The difference from Embodiment 1 or Embodiment 2 is that: on the basis of Embodiment 1 or Embodiment 2, further, the side wall of the laundry basket 20 is arranged obliquely, and extends obliquely outwards in a direction from bottom to top, as figure 1 , figure 2 with Figure 7 shown.

[0088] The side walls of the laundry basket 20 are inclined and extend outwards from bottom to top, so that the washing water flows upwards and outwards under the action of centrifugal force, so as to improve the dehydration and drainage effect of the laundry basket 20 .

[0089] Preferably, the angle between the side wall of the laundry basket 20 and the vertical direction is larger than 5°.

[0090] Limiting the included angle between the side wall of the laundry basket 20 and the vertical direction within a range greater than 5° ensures that the laundry basket 20 can have a good dehydration and drainage effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com