Pre-embedded reinforcement segment correction device and its correction method

A technology of pre-embedding steel bars and correcting devices, which is applied in the processing of building materials, construction, and building structure, etc., can solve the problems of underground construction efficiency and low vertical adjustment accuracy, and achieves convenient operation, high vertical adjustment accuracy, and high construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

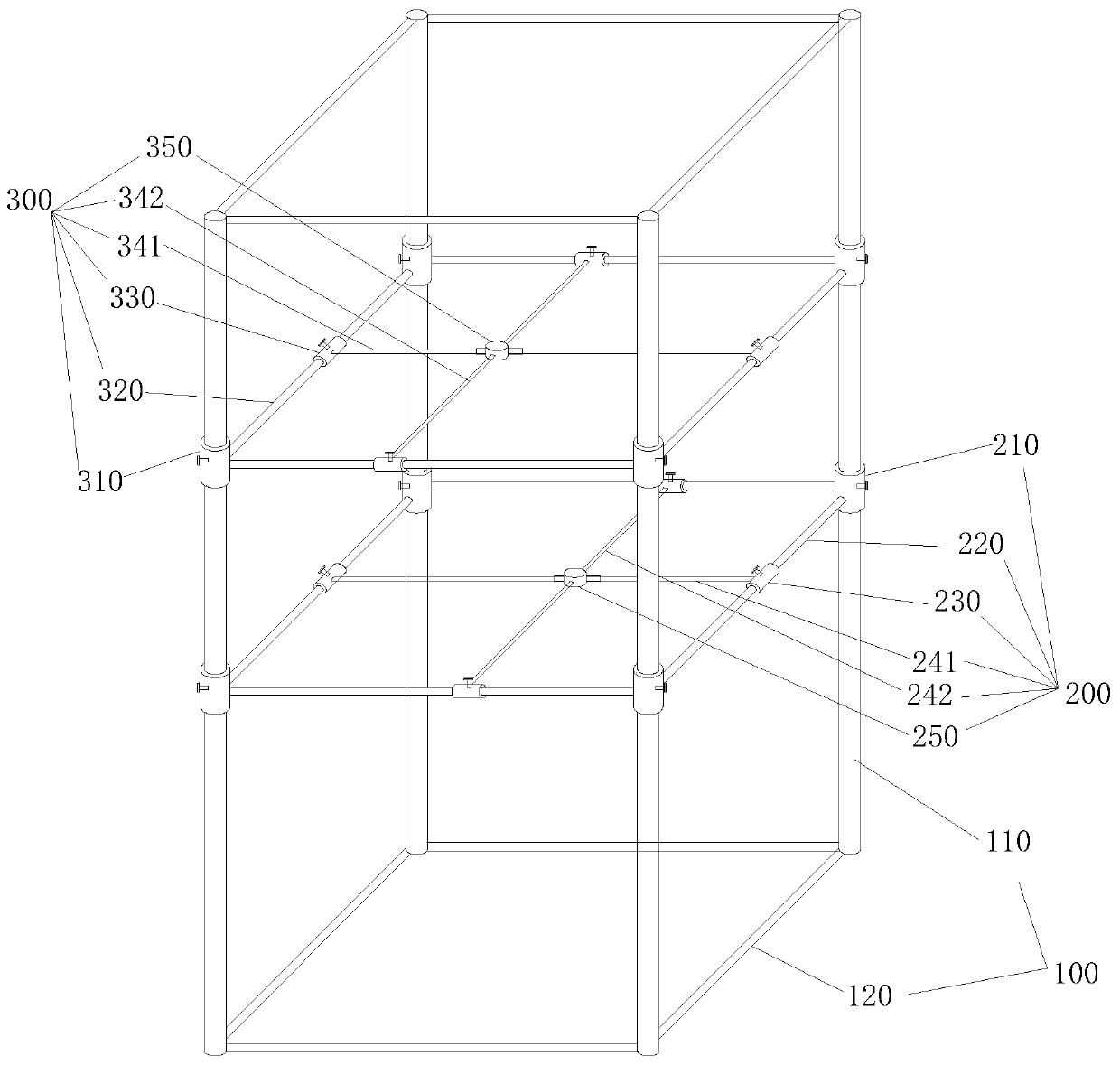

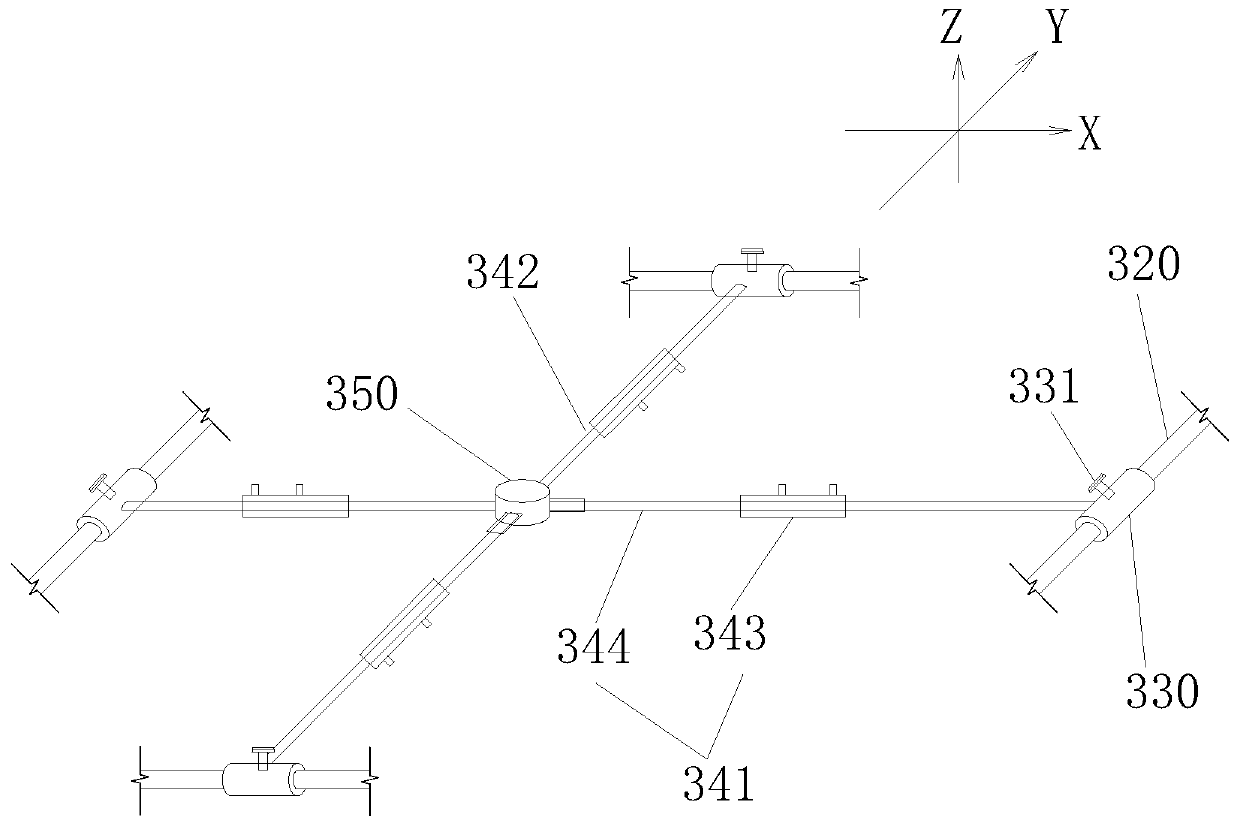

[0043] see figure 1 , figure 2 , image 3 with Figure 4 As shown, the following will combine Figure 1 to Figure 4 The gist of the present invention is further described. In this embodiment, the pre-embedded steel bar section correction device includes: a vertical adjustment frame 100 , a steel bar fixing assembly 200 and a steel bar correction assembly 300 located above the steel bar fixing assembly 200 .

[0044] Such as figure 1 As shown, the vertical adjustment frame 100 is a cuboid frame composed of four vertical rods 110 and eight horizontal rods 120 at the bottom and top of the vertical rods 110 . The sagging frame 100 is used to support the steel bar fixing assembly 200 and the steel bar correction assembly 300 .

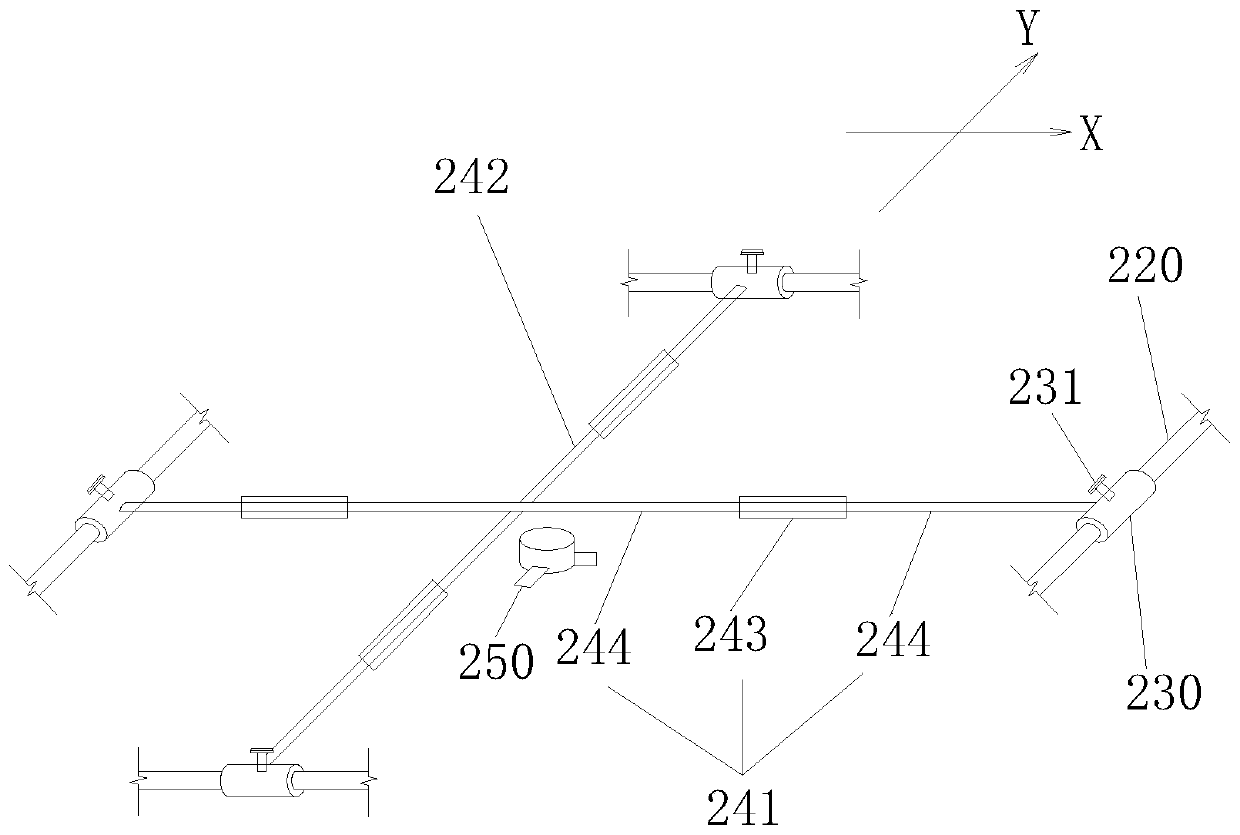

[0045] Such as figure 1As shown, the steel bar fixing assembly 200 includes four first vertical adjustment limit sliders 210, four first horizontal guide rails 220, four horizontal adjustment limit sliders 230, one fixed horizontal bar 241 and one f...

Embodiment 2

[0054] refer to Figure 5 , the present invention also provides a segmental correction method for pre-embedded reinforcement, combined below Figure 1 to Figure 5 , to further describe the correction method, which specifically includes the following steps:

[0055] S1. Determine the number N of correction segments of the pre-embedded steel bar 410 according to the bending point of the pre-embedded steel bar 410 , and fix the pre-embedded steel bar sectional correction device so that the pre-embedded steel bar 410 is in the middle of the adjusting frame 100 . Such as Figure 4 As shown in , the pre-embedded steel bar 410 on the platform 400 undergoes multi-stage bending deformation, and the break point and bending point of the pre-embedded steel bar 410 are taken as control points. Therefore, the pre-embedded steel bar 410 includes four parts A, B, C, and D Control points, the three correction segments are AB correction segment, BC correction segment, and CD correction segmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com