One-pillar-one-pillar fine vertical adjustment device, system and method

A fine, steel column technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of inconvenient concrete pouring, low degree of automation, and low centering accuracy, and achieve automatic vertical adjustment and improved Construction efficiency, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

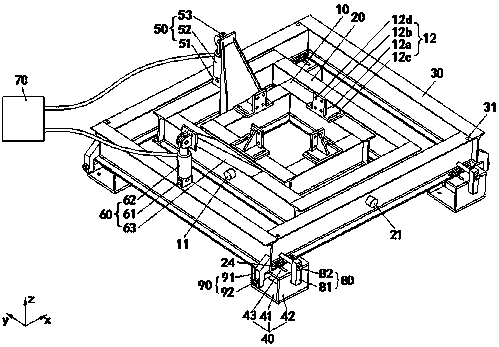

[0039] Example 1: Combining figure 1 Illustrate that the fine vertical adjustment device of one column and one pile of the present invention is used to adjust the verticality of the steel column of the bored pile, and it includes:

[0040] The inner rotating frame 10 is a hollow frame body, and the steel column can penetrate the inner rotating frame 10 and be rigidly connected with it;

[0041] The outer rotating frame 20 is sheathed on the outside of the inner rotating frame 10. The inner rotating frame 10 and the outer rotating frame 20 are arranged coaxially and spaced apart. Rotating frame 20;

[0042] The fixed frame 30 is sleeved on the outer side of the outer rotating frame 20, the fixed frame 30 and the outer rotating frame 20 are coaxial and arranged at intervals, and the outer rotating frame 20 is movably connected to the fixed frame 30 through a pair of outer frame bearings 21 located on its center line. And the axes of the inner frame bearing 11 and the outer fra...

Embodiment 2

[0055] Example 2: Combining figure 1 Describe the fine vertical adjustment system of one column and one pile of the present invention, which includes: a fine vertical adjustment device for one column and one pile installed on the ground at the top of the underground borehole, and a spirit level (not shown in the figure) installed on the steel column, and The spirit level is connected with the control station 70 of the column-by-pillar fine vertical adjustment device for signal connection. After the steel column runs through the inner rotating frame 10 and is fixed by the connecting seat 12, adjust the level adjustment component 1 80 and the level adjustment component 2 90 respectively, so that the center position of the steel column meets the construction requirements, and then tighten the base 40 and the fixing frame by bolts 30. The control station 70 receives the data of the level instrument on the steel column and analyzes and calculates it. By controlling the expansion an...

Embodiment 3

[0056] Embodiment 3: The fine vertical adjustment method of one column and one pile of the present invention, the specific steps are as follows:

[0057] S1: Assemble the one-column-one-pile fine vertical adjustment device as described in Embodiment 1, and the one-column one-pile fine vertical adjustment device is installed above the underground borehole, so that the inner rotating frame 10 is facing the center of the underground borehole, and more The bottom of the first base 40 is connected to the ground, the first hydraulic cylinder 52 and the second hydraulic cylinder 62 communicate with the control station 70 through hydraulic oil pipes, a level is installed on the top of the steel column and hoisted into the underground drill hole, and the top of the steel column passes through the connecting seat 12 and the control station 70. The inner rotating frame 10 is rigidly connected;

[0058] S2: adjust the level adjustment component 1 80 and the level adjustment component 2 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com