Lattice column triaxial automatic wireless real time hanging system and method

A lattice column and automatic technology, which is applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems of low vertical adjustment efficiency, low degree of automation, and low vertical adjustment accuracy, so as to reduce the pouring height of concrete and improve automation degree, the effect of improving the vertical adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention is described clearly and completely:

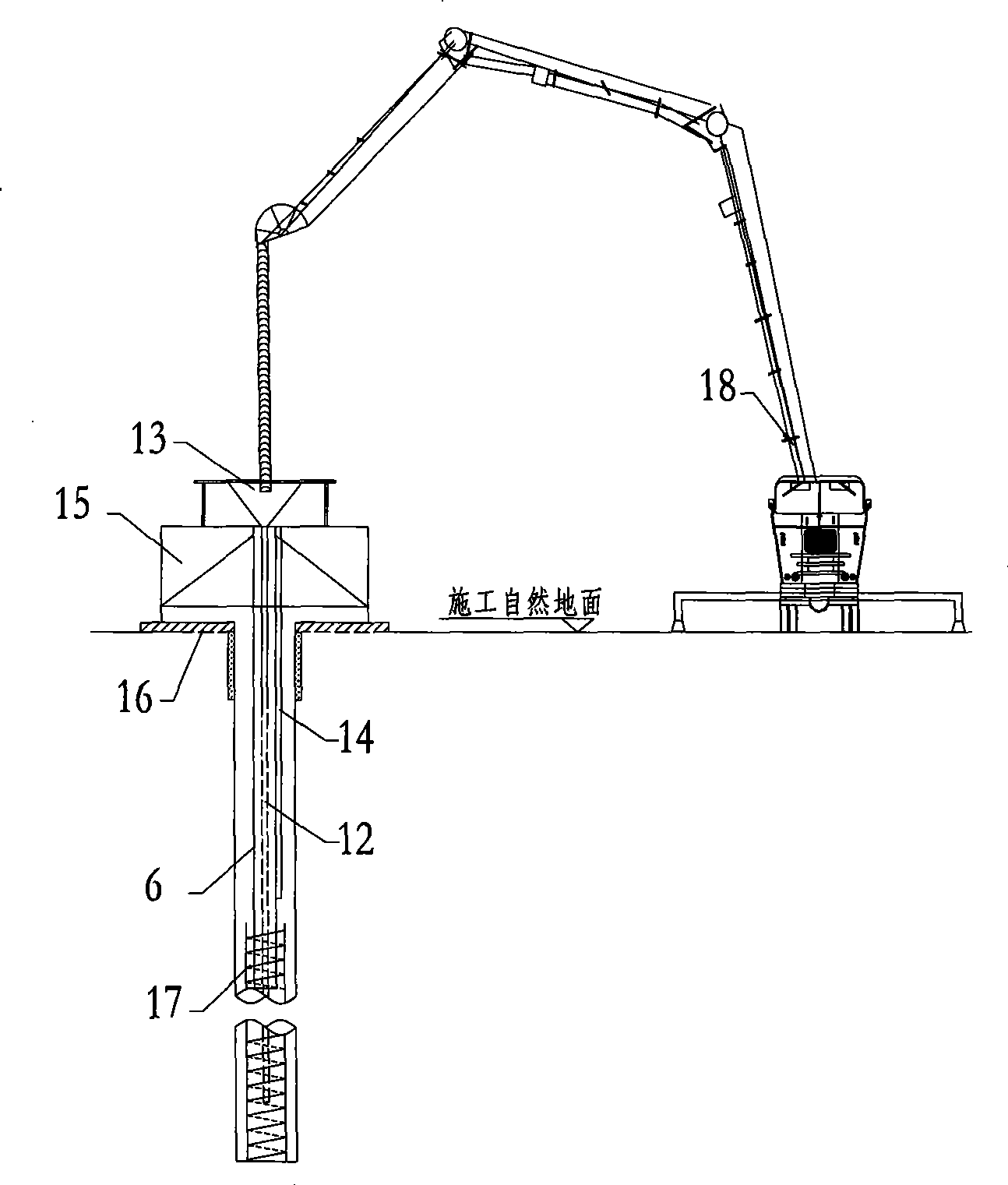

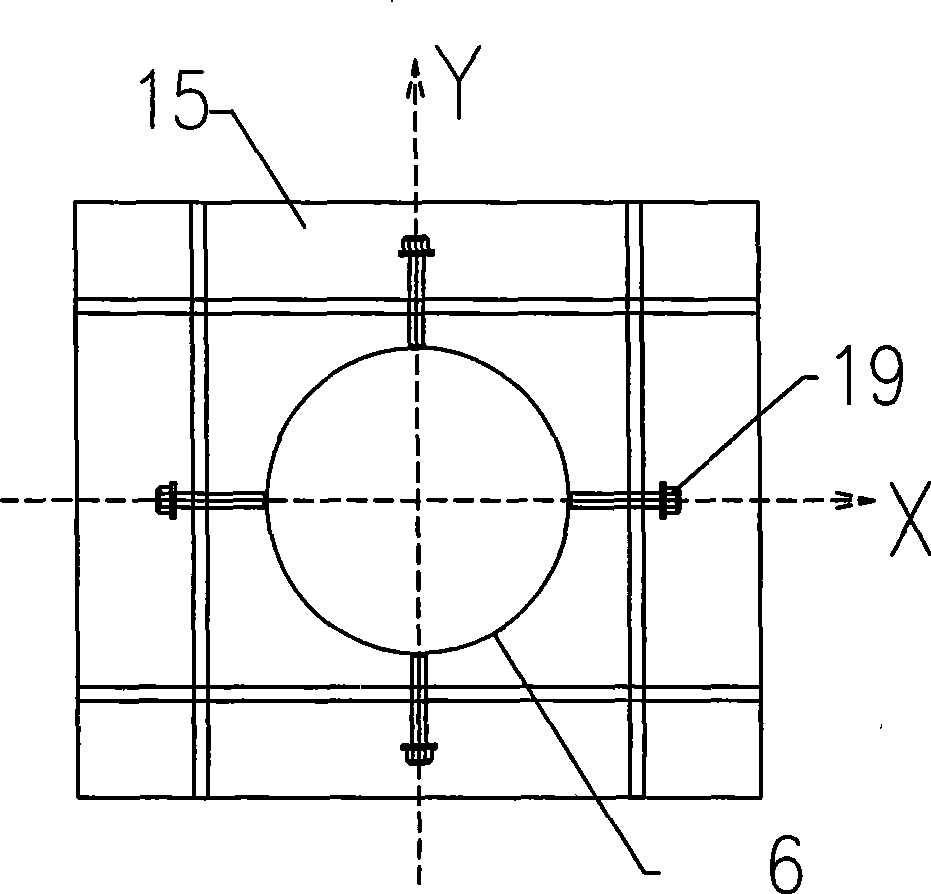

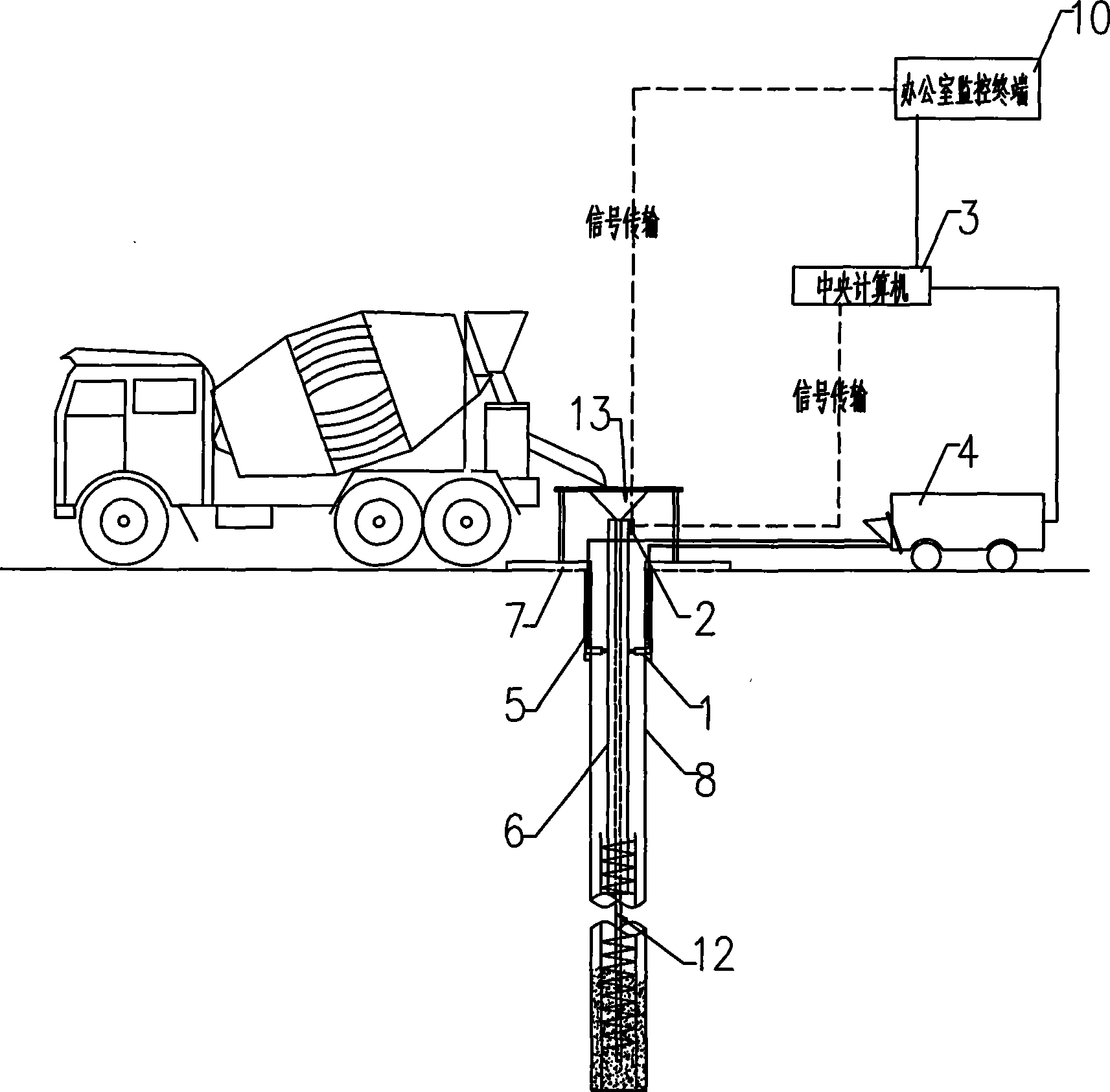

[0041] See image 3 , and with reference to Figure 4a and Figure 4b , this lattice column vertical adjustment system includes: the casing 5 arranged on the top of the pile hole 8, and the ground fixed connection mechanism installed on the ground of the pile hole 8, and also includes: an inclinometer device, an adjustment device and a control device. The inclinometer is installed on the lattice column 6 . The lattice column 6 is placed in the pile hole 8, and the casing 5 is placed outside the neck of the lattice column 6. The adjustment device includes a connected three-axis adjustable mechanism and a driving device, and the three-axis adjustable mechanism is arranged between the casing 5 and the lattice column 6 . The control device is a central computer 3 . The inclinometer device and the adjustment device are respectively connected with the control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com