Valve trains for internal combustion engines

A valve mechanism and internal combustion engine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem of expensive actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

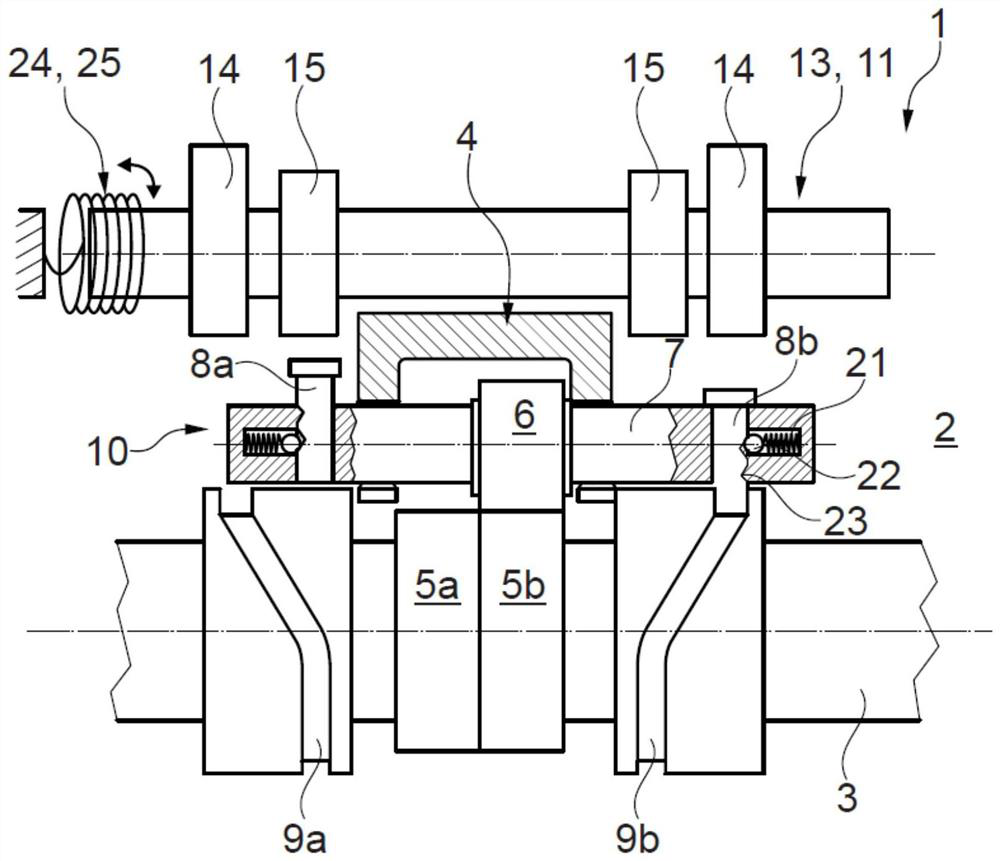

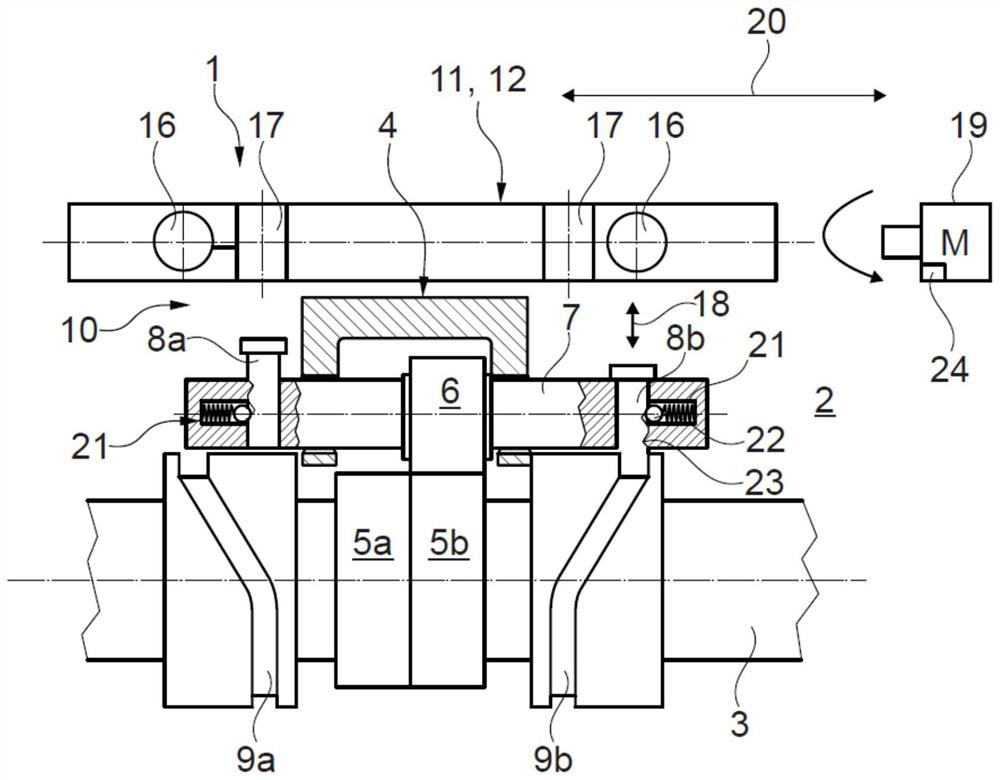

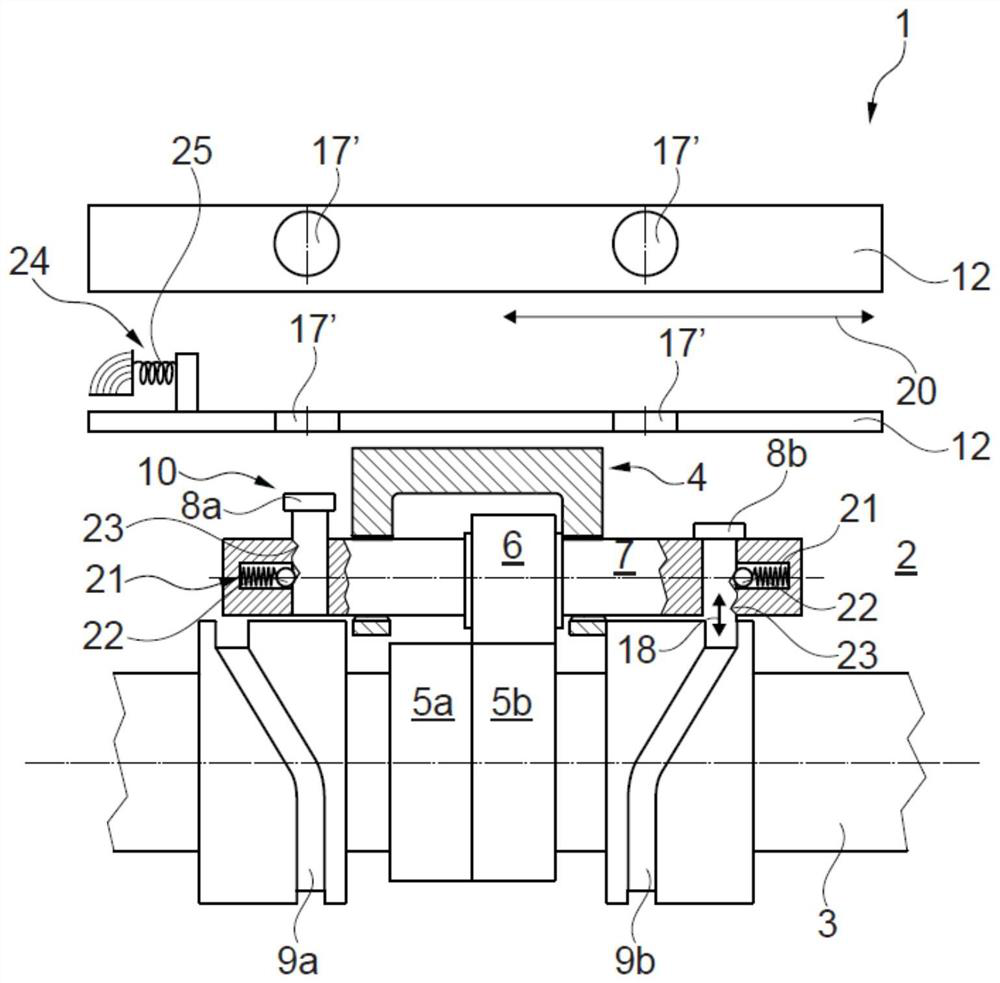

[0020] according to Figure 1 to Figure 3 , a valve train 1 of a not shown internal combustion engine 2 according to the invention has a camshaft 3 and a cam follower 4 . A first cam 5 a and a second cam 5 b are here arranged in a torque-resistant manner on the camshaft 3 , the cam profile of which cams can alternatively be picked up by the cam follower 4 and transferred to the associated valve, for example of the cylinder. Inlet valve or outlet valve. In this case, the two cams 5 a , 5 b have different cam profiles, wherein theoretically, for example, the cam 5 b can consist only of a base circle and thus cause the cylinders to separate.

[0021] In the first position, the roller 6 of the cam follower 4 picks up the cam profile of the cam 5a, while in the second position the roller 6 of the cam follower 4 is drivingly connected to the second cam 5b and thus picks up its profile. The roller 6 is here rotatably mounted on a roller needle 7 . According to the invention, an ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com