Air-conditioner internal unit and air conditioner

An air conditioner internal unit and cyclone technology, applied in the field of air conditioners, can solve the problems of low working pressure, difficult to reduce the size of commercial air conditioners, and use occasions where limited installation space is required, so as to achieve compact installation space and small installation space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

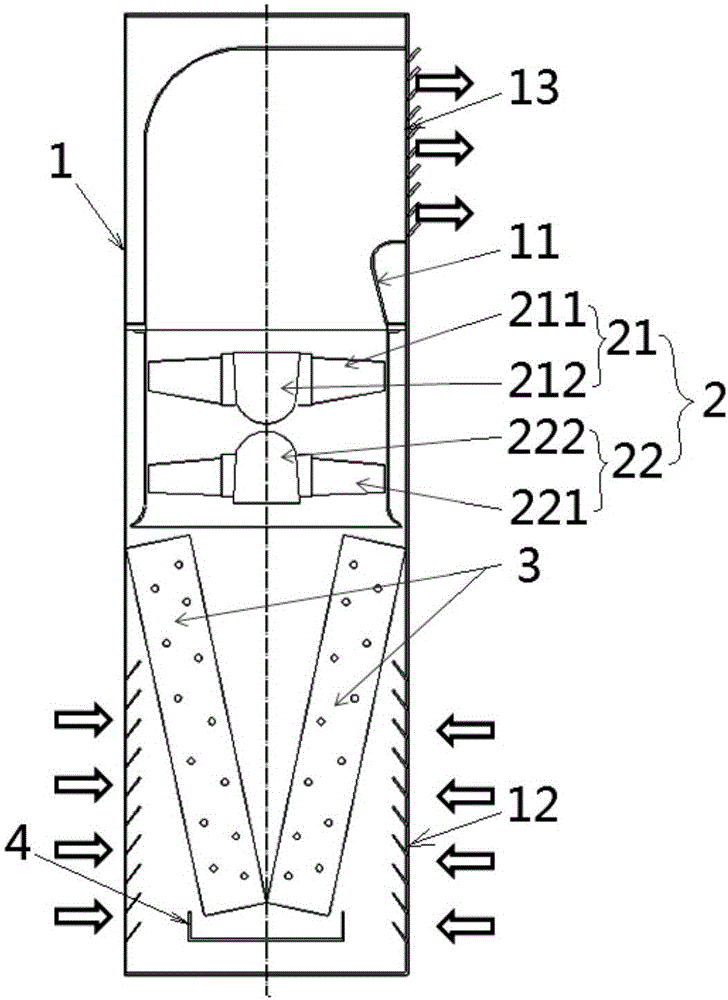

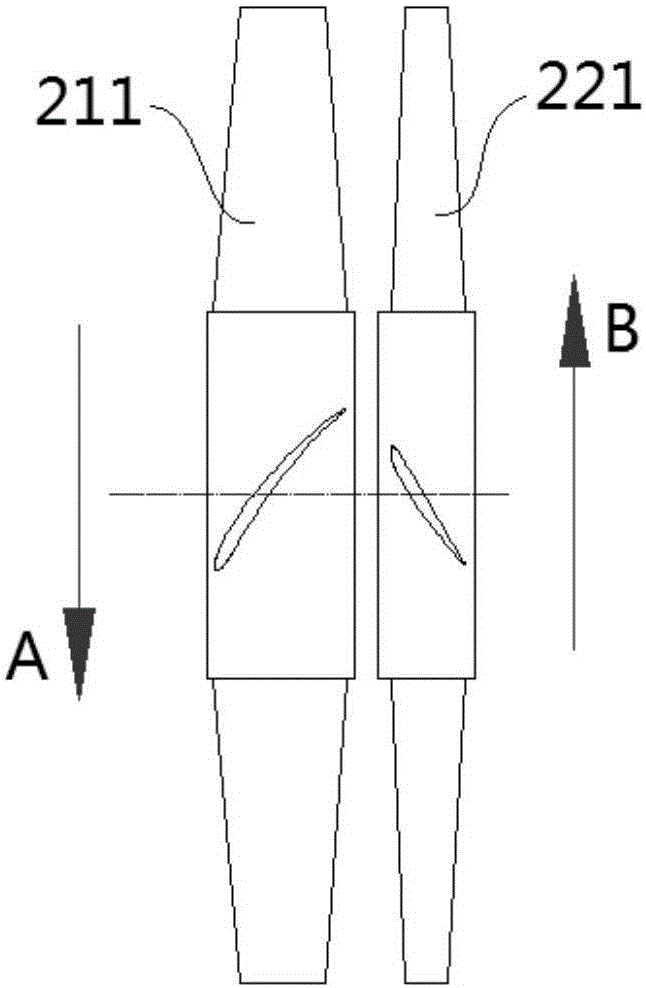

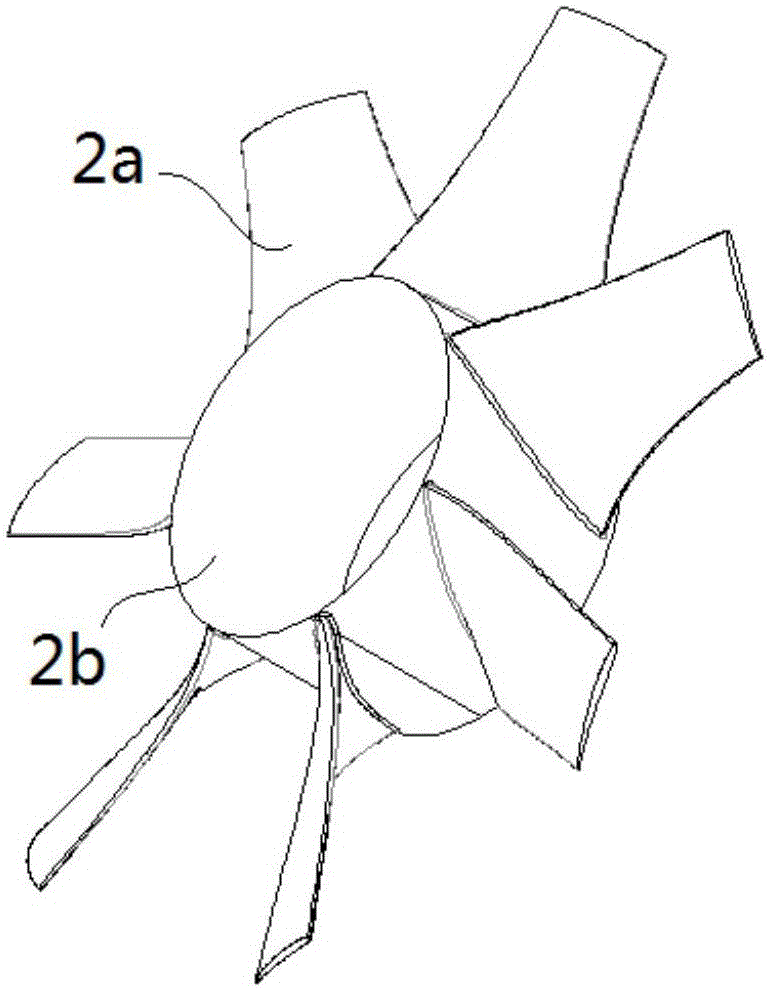

[0021] Such as figure 1 Shown is a schematic structural view of an embodiment of the air conditioner inner unit of the present invention. In this embodiment, the air conditioner internal unit includes: an internal air duct 11 and a counter-cyclone fan 2 . The internal air duct 11 communicates with the air inlet 12 and the exhaust port 13 of the indoor unit of the air conditioner, and the counter-cyclone fan 2 is arranged in the internal air duct 11 to guide the air flow from the air inlet 12 to the exhaust port along the internal air duct 11 13.

[0022] The internal air duct 11 can be formed inside the body 1 of the air conditioner, and the air inlet 12 and the exhaust port 13 can refer to figure 1 As shown, they are respectively arranged at both ends of the internal air duct 11 . In another embodiment, the air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com