Combined throttling valve debugging tool

A technology for debugging tooling and throttle valves, which is applied to refrigeration components, fluid circulation arrangements, mechanical equipment, etc., can solve problems such as time-consuming and labor-intensive, and achieve the effects of ensuring stability, improving debugging test efficiency, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

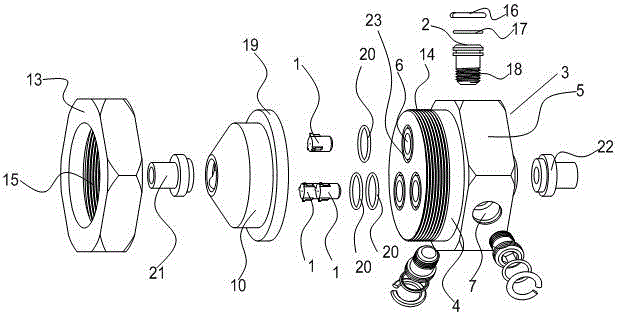

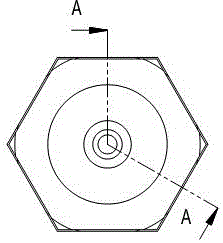

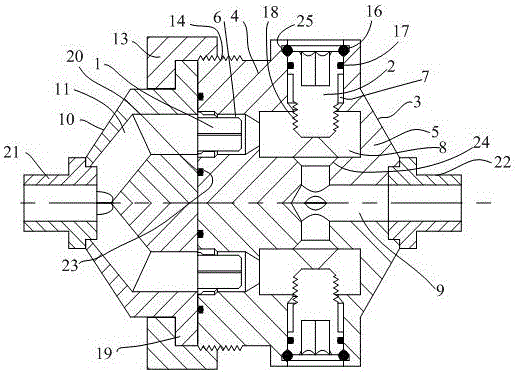

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] refer to figure 1 and image 3 , the combined throttle valve debugging tooling of the present invention includes a throttle valve core 1, a cut-off plug 2, a throttle seat 3, a shunt cover 10, and a fastener 13; the throttle seat 3 includes a coaxial and integral connection 4 and the cut-off plug installation part 5, a plurality of first assembly holes 6 are opened on the connection part 4 along the direction parallel to its axis, and a throttle valve core 1 is installed in the first assembly hole 6; A plurality of second assembly holes 7 are opened in the direction, and a cut-off plug 2 is installed in the second assembly hole 7; inside the cut-off plug installation part 5, there are a plurality of radially extending throttle channels 8 and one axially extending One end of the throttle flow channel 8 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com