Multifunctional anti-extrusion neutral section passing debugging tool for motor train unit

A debugging tooling and multi-functional technology, applied in railway vehicle testing and other directions, can solve the problems of low debugging efficiency and single debugging tooling function, and achieve the effect of improving debugging test efficiency, simple structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

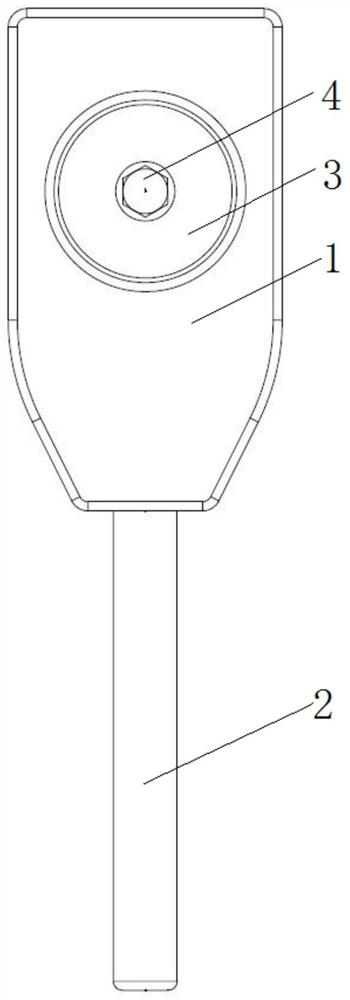

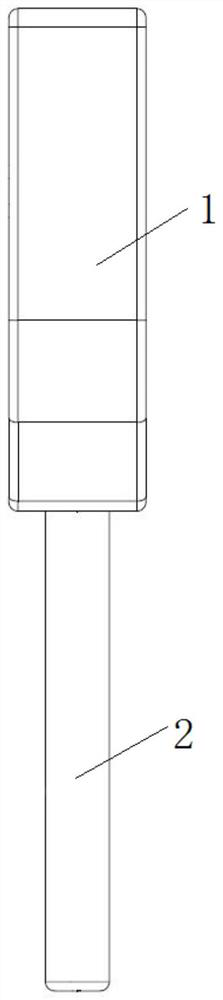

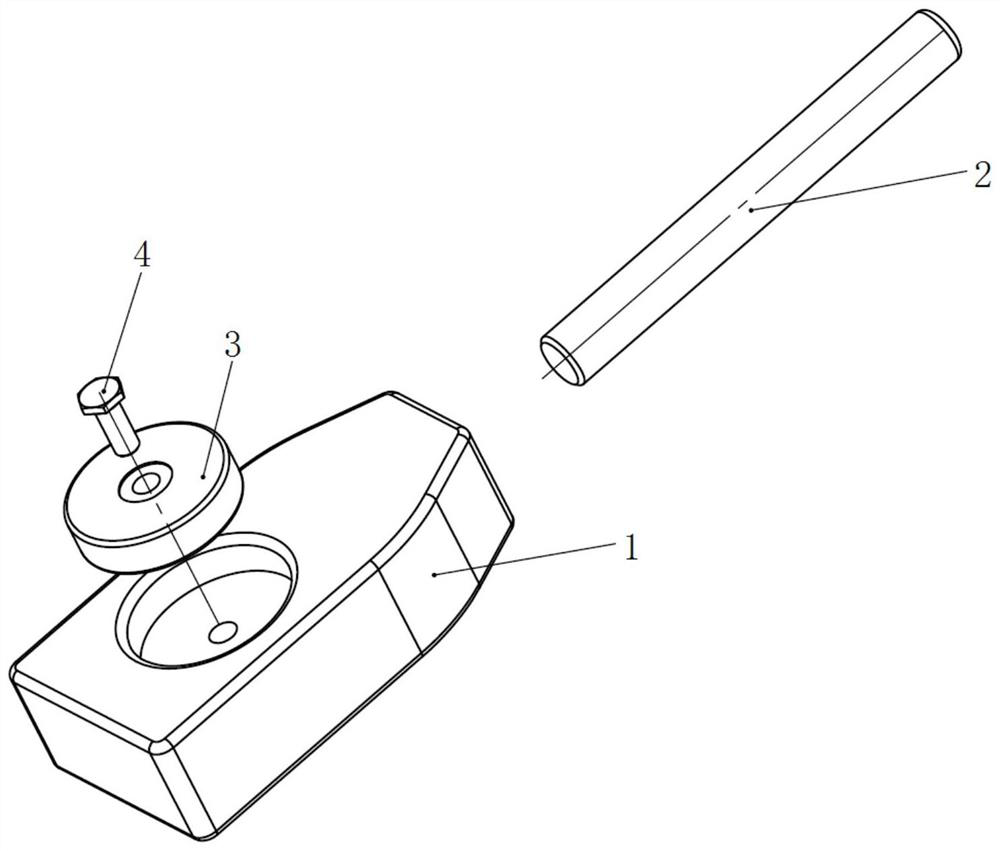

[0025] Such as Figure 1 to Figure 3 As shown, a multifunctional anti-extrusion over-phase debugging tool for EMUs, including a debugging tool body 1, a handle 2, and a strong magnet 3, the top of the debugging tool body 1 is detachably connected to the handle 2, and the side of the debugging tool body 1 is connected to the strong magnet 3 fixed connections. The advantage of the detachable handle 2: According to the size requirements of the debugging tool during the 98% door closing test of different models of plug doors, different types of handles 2 that meet the test requirements can be replaced at any time to adapt to the test requirements of different models, and the debugging tool of the present invention can be added Versatility, reducing debugging costs.

[0026] Specifically in this embodiment, the upper part of the debugging tool body 1 is screwed to the handle 2 .

[0027] In this embodiment, as a preference, the end of the handle 2 is provided with an external thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com