Aeronautical blade profile machining error visualization method

A technology for aviation blade and surface processing, applied in design optimization/simulation, special data processing applications, measurement devices, etc., can solve the problem of low degree of visualization of detection information, visualization method of aviation blade surface processing errors, and inability to process aviation blade surfaces Efficient and accurate analysis of errors and other issues to achieve high analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, provide the specific embodiment of the present invention. It should be noted that the blades used in the embodiments are not specific, and the method of the present invention can be generally applied to the visual analysis of processing errors of conventional blades.

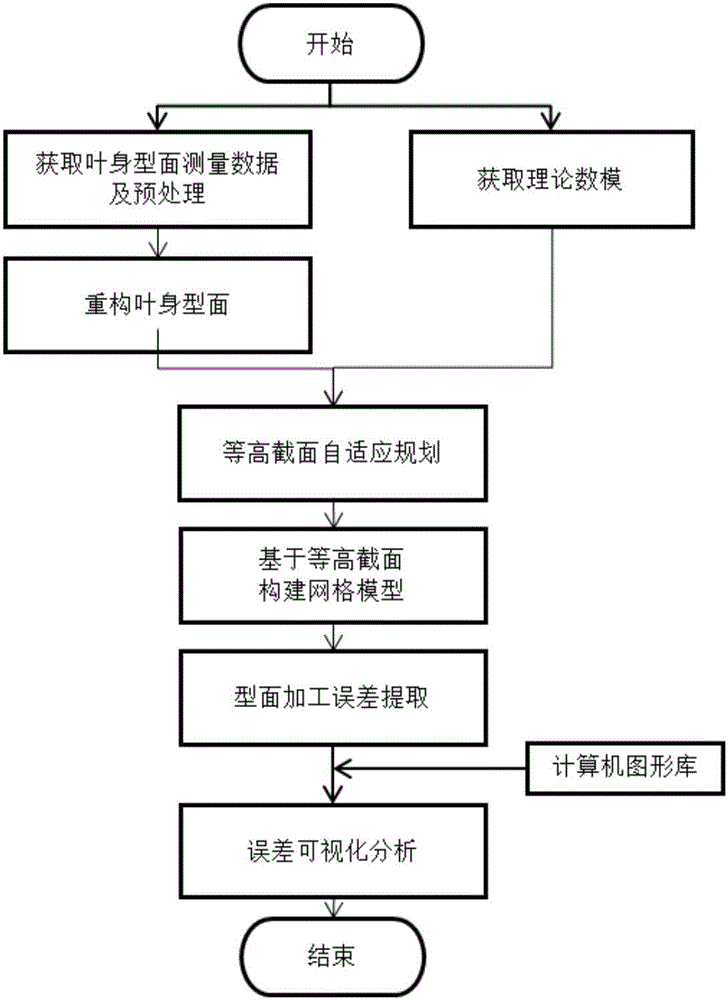

[0032] In this embodiment, a certain type of aviation blade is taken as an example. The specific process of the visual analysis method for the machining error of the airfoil profile is as follows: figure 1 shown, including the following steps:

[0033] S1: Obtain the measurement data of the airfoil profile

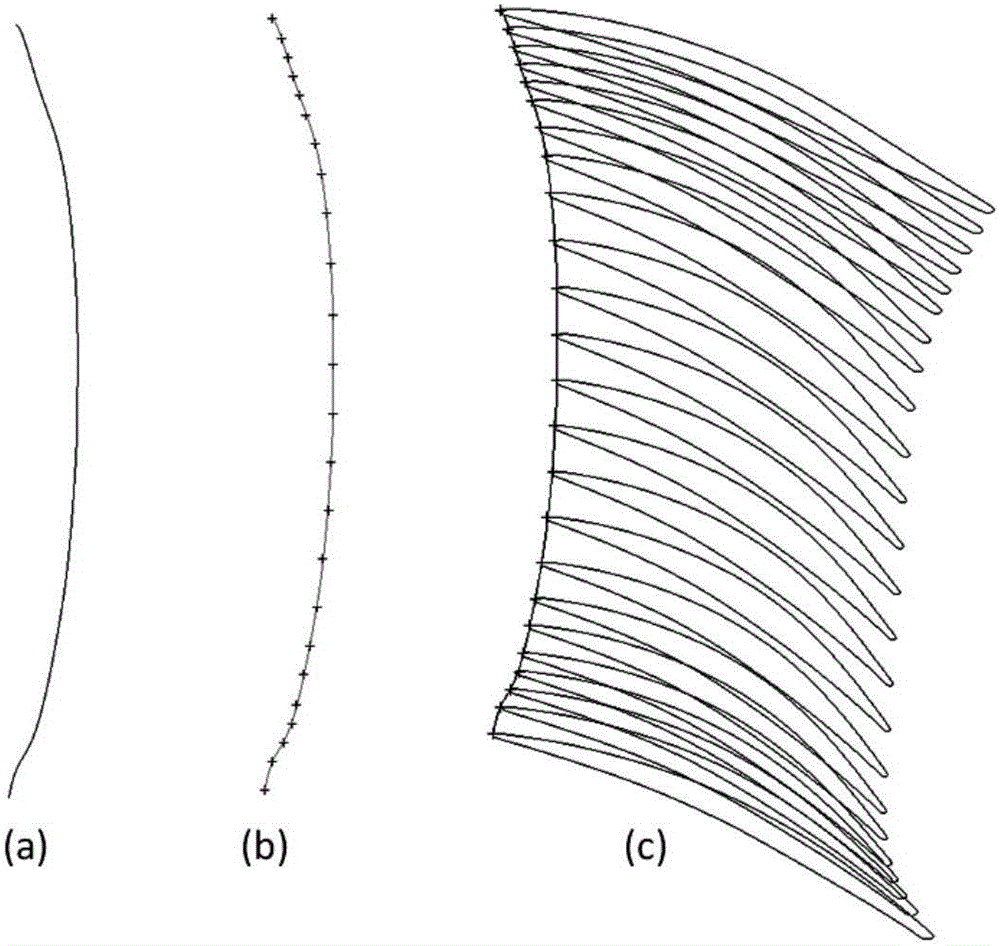

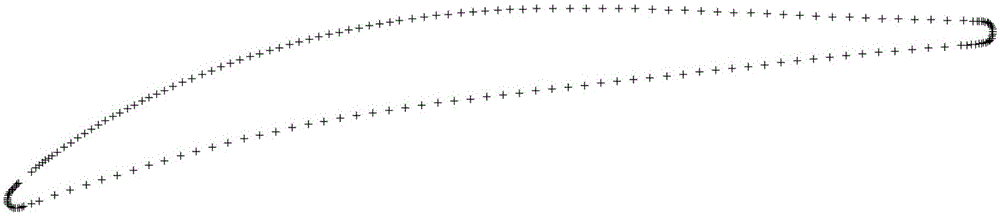

[0034] Specifically, the processed blade can be measured by the equal section method with a contact coordinate measuring machine, and the measurement data can be preprocessed accordingly to obtain accurate blade body measurement data, that is, the ordered measurement point set T i,j , where, i=1, 2...n; j=1, 2...m, n is the number of layers in the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com