Positioning structure of miniature metal sheet in injection mold

A positioning structure and metal sheet technology, applied in the direction of coating, etc., can solve the problems of large size, increased cost, and easy falling off of steel sheets, and achieve the effects of reducing mold repair costs, improving production efficiency, and saving cutting processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

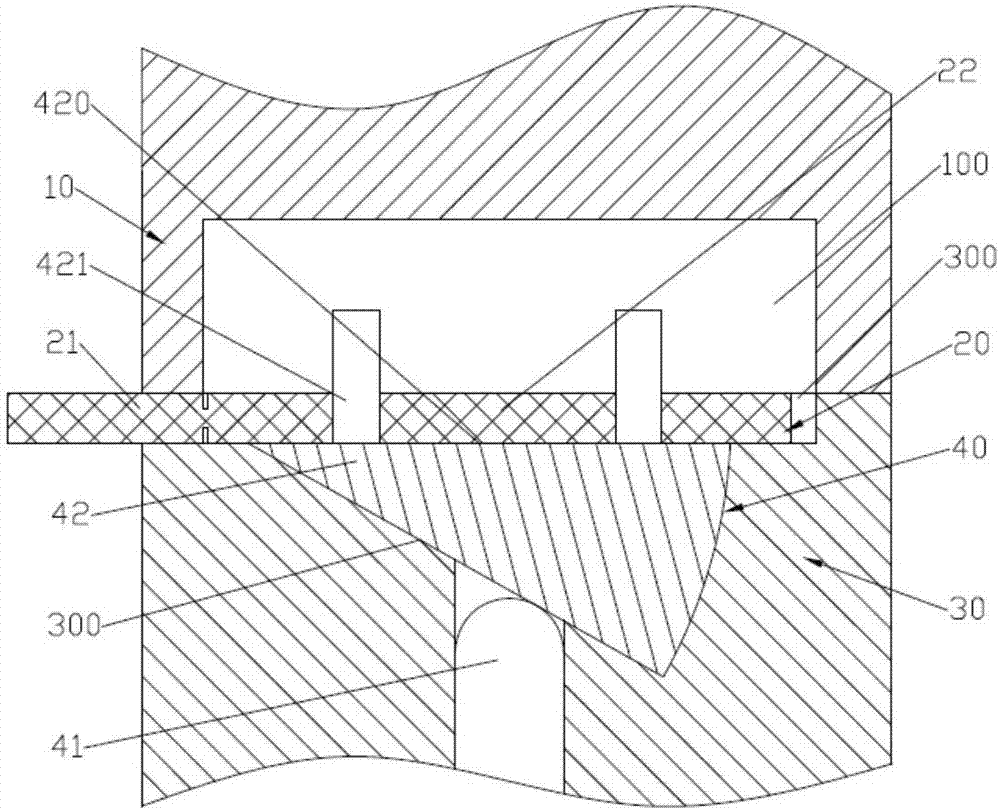

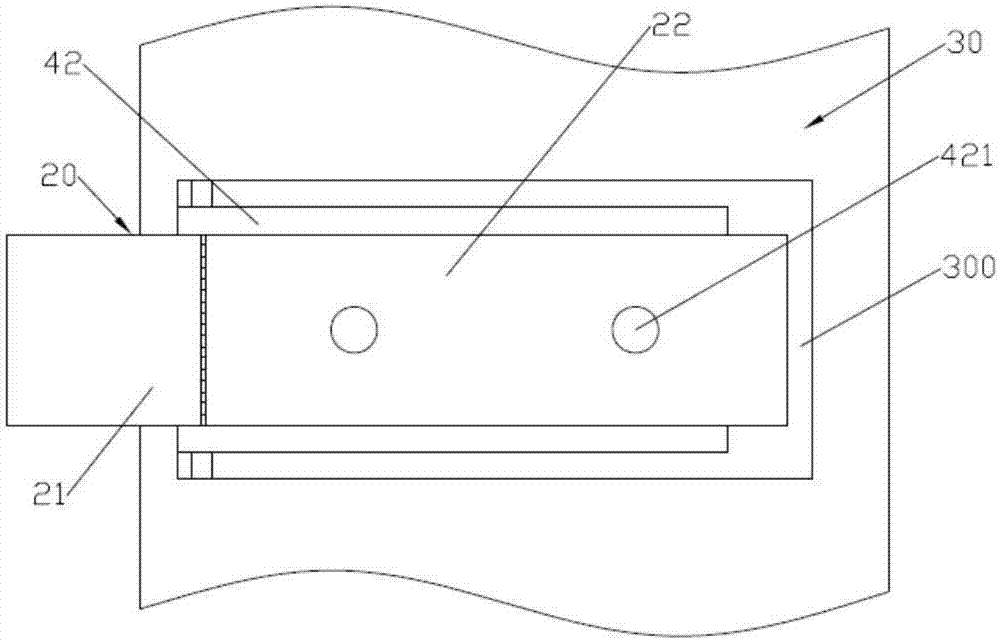

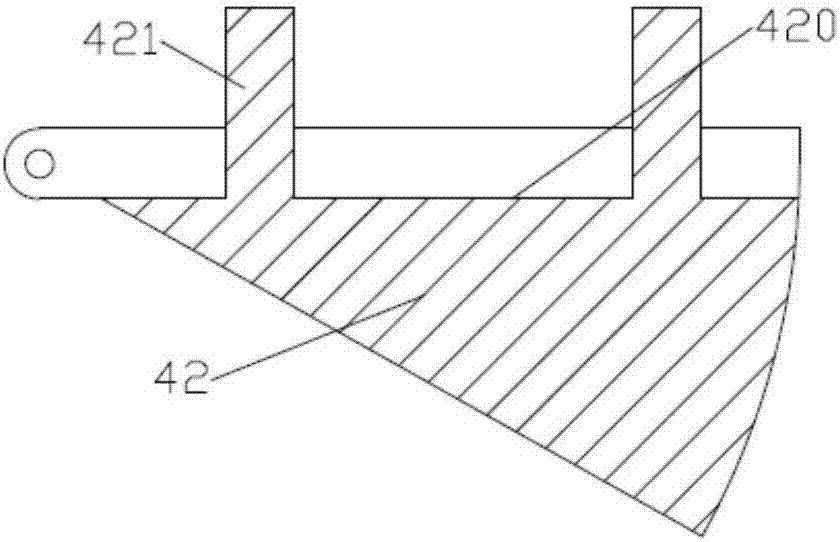

[0015] like Figure 1 ~ Figure 3 As shown, a positioning structure for small metal sheets in an injection mold includes an upper mold 10, a metal sheet unit 20, a lower mold 30 and a supporting breaking device 40; the lower end surface of the side wall of the upper mold 10 is formed with a rectangular breaking groove 100 The sheet metal unit 20 is made up of the sheet metal body 21 on the left and the supporting sheet 22 on the right; The end surface is formed with a placement groove 300 that runs through the left side; the supporting breaking device 40 includes a rotating breaking block 42; the left end of the rotating breaking block 42 is hinged between the front and rear side walls of the placement groove 300; the upper end surface of the rotating breaking block 42 is formed with left and right through The limit groove 420; when the upper end surface of the rotating breaking block 42 is in a horizontal state, the bottom surface of the limit groove 420 is flush with the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com