Multifunctional punching die capable of rotating automatically

A technology of automatic rotation and stamping dies, applied in the field of stamping dies, can solve the problems of lack of flexibility in production and manufacturing, and achieve the effects of high usable value, increased diversity, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

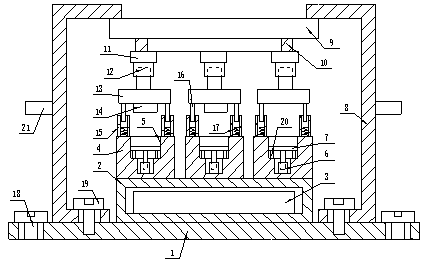

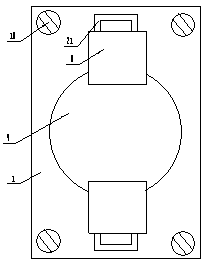

[0014] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, an automatic rotating multifunctional stamping die includes a lower fixing seat 1, the upper surface of the lower fixing seat 1 is fixedly connected with a circular lower mold seat 2, and the inside of the circular lower mold seat 2 is a hollow structure, The circular lower mold base 2 is provided with a sound-absorbing sponge 3, and the upper surface of the circular lower mold base 2 is fixedly connected with a plurality of lower molds 4, each of which is processed with a concave mold cavity 5 on the upper surface of the lower mold 4. , the inner and lower surface of each concave mold cavity 5 is processed with a rectangular groove, and each of the inner and lower surfaces of the rectangular groove is fixedly connected with an electronically controlled telescopic strut 6 with the telescopic end upward, and each of the electrically controlled The tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com