Vacuum absorbing device

A vacuum adsorption and vacuum technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of complex structure of thrust adsorption mechanism, limit the application of adsorption mechanism, and low working reliability, so as to save manpower and material resources, improve efficiency, and work Safe and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

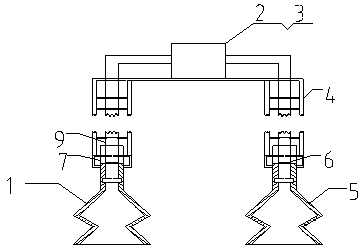

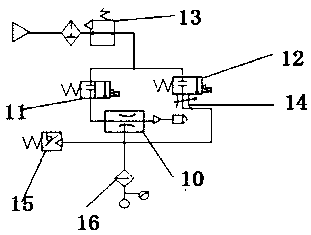

[0012] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

[0013] like figure 1 figure 2 A vacuum adsorption device is shown, which includes an adsorption mechanism 1, a vacuum mechanism 2, a pneumatic mechanism 3 and a connecting mechanism 4; the output end of the vacuum mechanism 2 is connected to the input end of the adsorption mechanism 1, and the pneumatic mechanism 3 controls the vacuum mechanism 2 and the adsorption mechanism 1; one end of the connection mechanism 4 is connected to the adsorption mechanism 1, and the other end is connected to the vacuum mechanism 2;

[0014] The adsorption mechanism 1 includes a short bellows type suction cup 5, a sealing felt 6, and a gas distribution interface 7; the short bellows type suction cup 5 has a conical structure, and a vacuum channel is opened in the middle of the short bellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com