Suction cup sucking device

A suction cup and disc body technology is applied in the field of negative pressure adsorption to achieve the effect of enhancing negative pressure balance and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

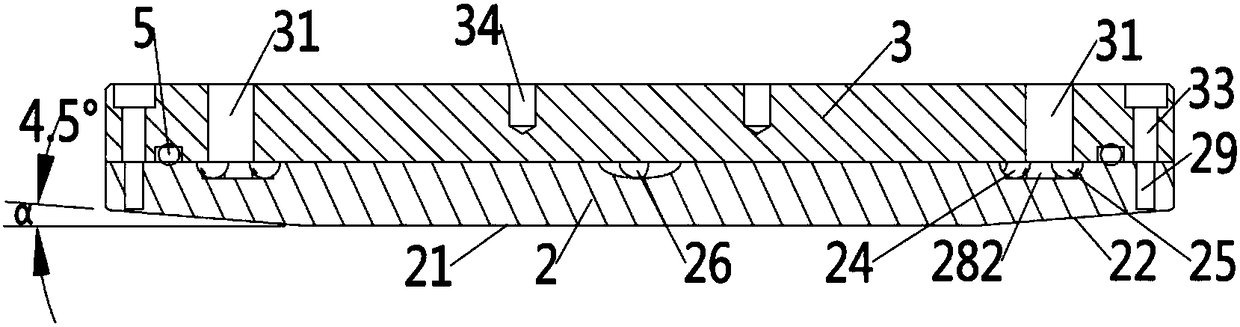

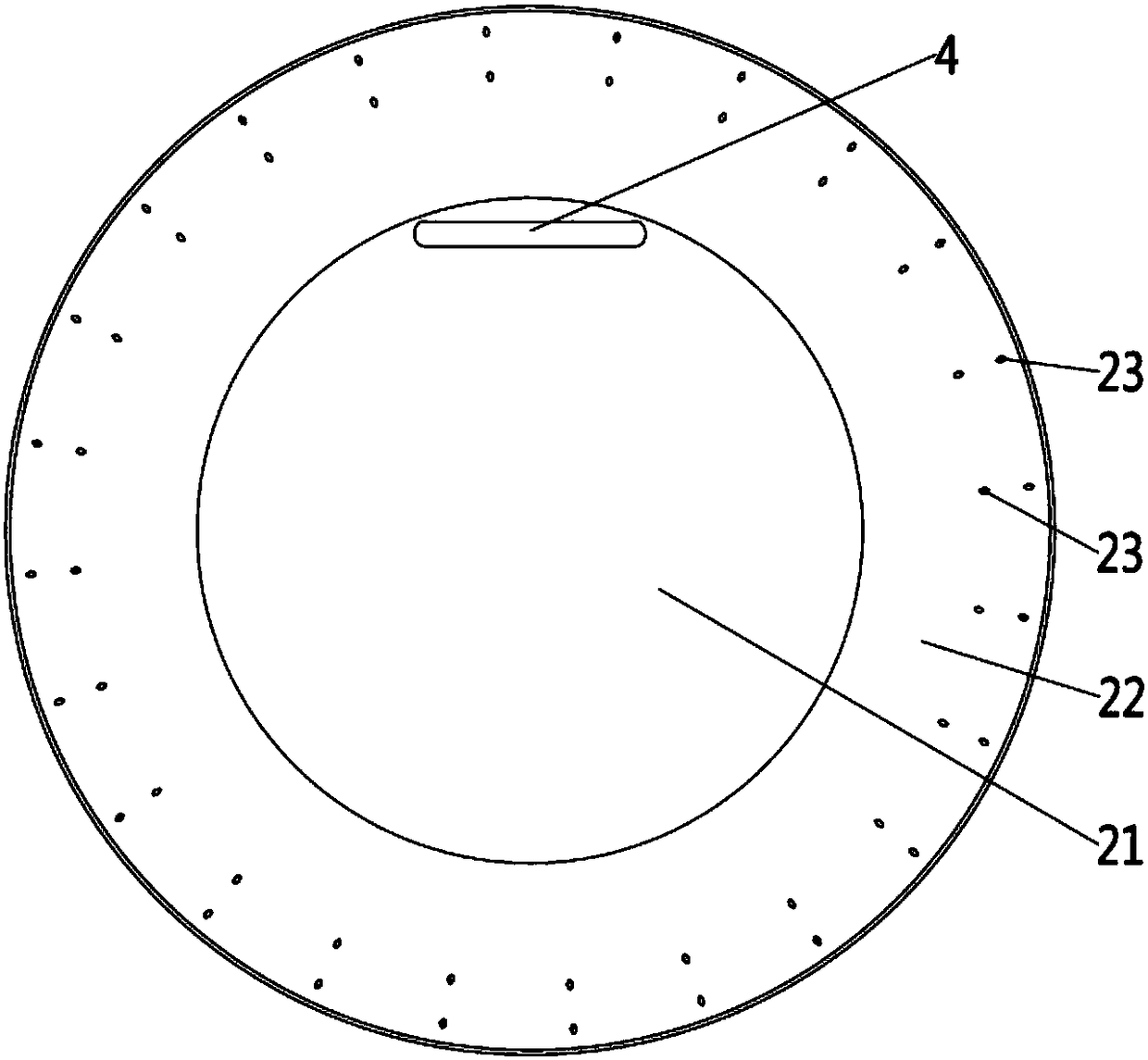

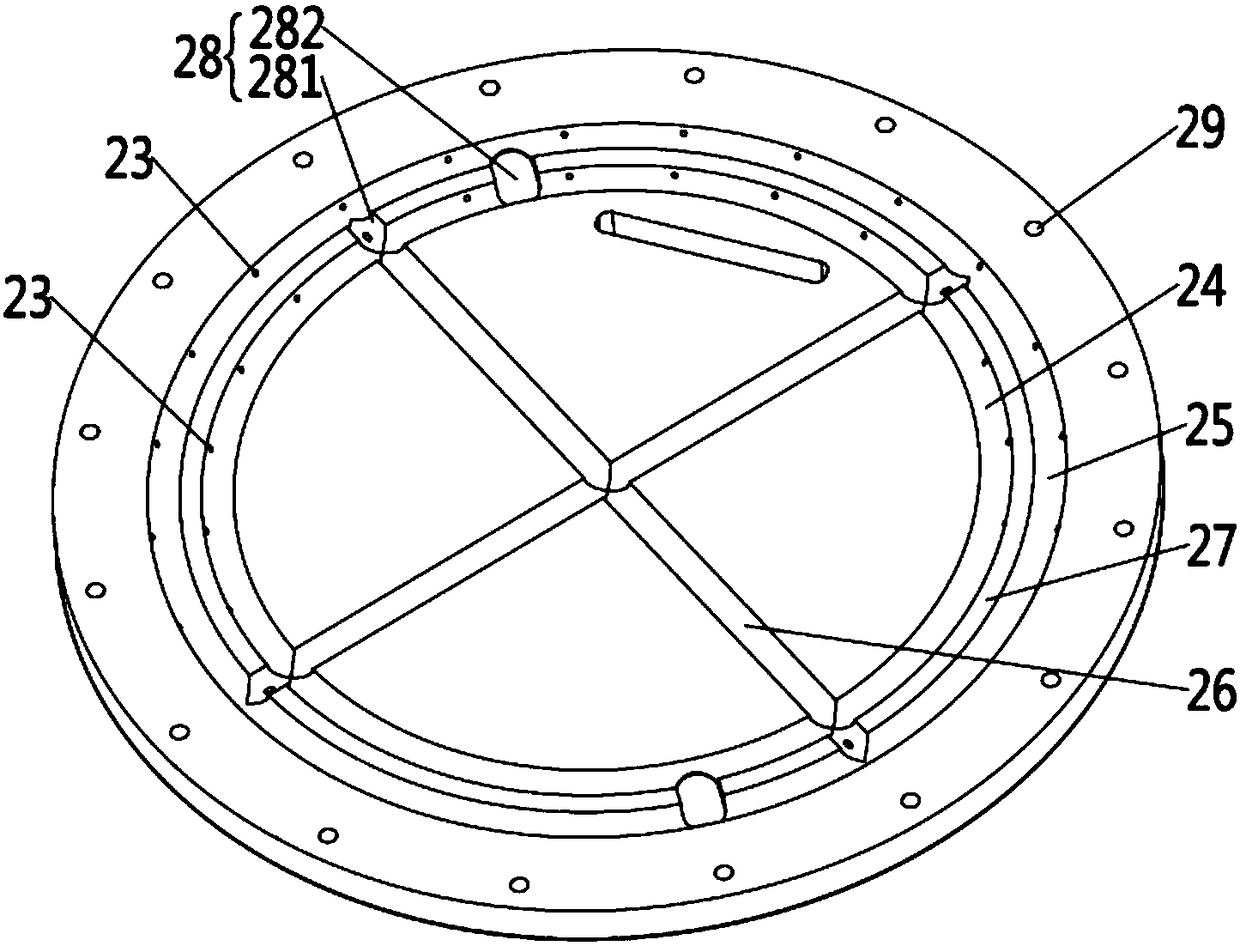

[0051] This embodiment provides a suction cup, such as figure 1 As shown, it includes a main body, and the main body includes a first disc body 2 , a second disc body 3 and a sealing ring 5 . A hollow cavity is formed between the second disc body 3 and the first disc body 2 .

[0052] Such as figure 1 , Figure 4 as well as Figure 5 As shown, the second disc body 3 is provided with an air extraction hole 31 , a sealing groove 32 , a first through hole 33 and a third through hole.

[0053] The second disc body 3 is preferably a disc-shaped structure, and its two circular surfaces serve as the inner wall surface and the outer wall surface respectively.

[0054] The outer peripheral edge of the second disc body 3 is provided with first through holes 33 extending from the inner wall surface to the outer wall surface, for example, several first through holes 33 are evenly distributed along the circumference of the second disc body 3, and the first through holes 33 for coopera...

Embodiment 2

[0072] This embodiment provides a suction device. Compared with the structure of the suction device provided in Embodiment 1, the only difference is that the detection device may not include a light-emitting element and a photosensitive element, but uses a weight detection element to pair the suctioned The air-permeable material is weighed, and the number of sheets of the air-permeable material absorbed is measured by weighing. At this time, the detection hole 4 can be cancelled.

Embodiment 3

[0074] This embodiment provides a suction cup. Compared with the structure of the suction cup provided in Embodiment 1 or 2, the only difference is that the angle α formed between the support surface 21 and the adsorption surface 22 is 3°; further The included angle α formed between the support surface 21 and the adsorption surface 22 is 9°; further, it can be 4°, 6° and other angles in the range of 3°-9°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com