Wind-proof protecting wall used for construction site

A technology for construction sites and protective walls, applied in construction, protective equipment, etc., can solve the problems of only dismantling, troublesome paving, easy to dump, etc., to avoid being blown over by the wind and facilitate transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

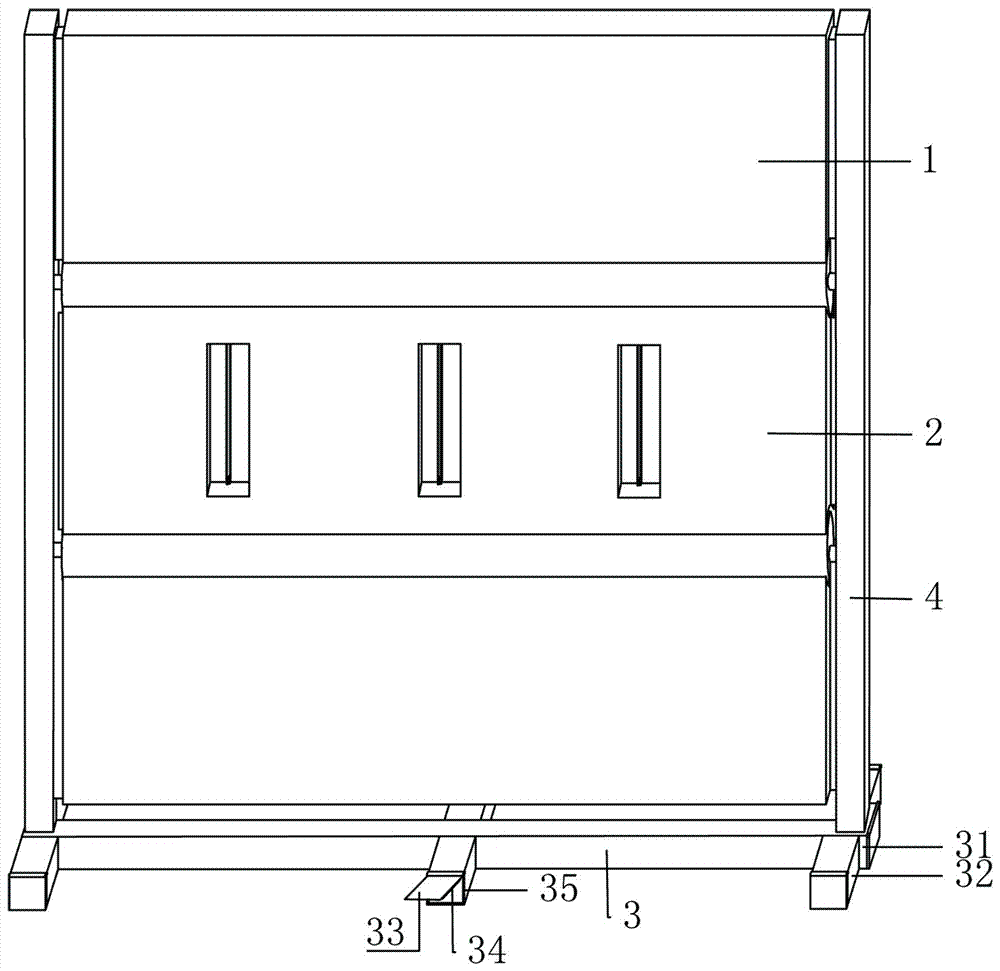

[0022] refer to Figure 1-4 As shown, a wind-resistant protective wall for a construction site in this embodiment includes several repeating units, and each unit includes two first guard plates 1, second guard plates 2, base 3 and two installation columns 4. The base 3 includes a hollow horizontal support rod 31 and a number of hollow longitudinal support rods 32. The horizontal support rod 31 and the longitudinal support rod 32 intersect vertically. The ends of the horizontal support rod 31 and the longitudinal support rod 32 are hinged with a cover plate 33 , the inner surface of the cover plate 33 is provided with a magnetic piece 34, a lead weight 35 is inserted in the horizontal support rod 31 and the longitudinal support rod 32, and the end of the lead weight 35 is fixed with an iron sheet; the bottom ends of the two mounting columns 4 are fixed on the horizontal At both ends of the support rod 31, two first guard plates 1 are symmetrically arranged on the upper and lowe...

Embodiment 2

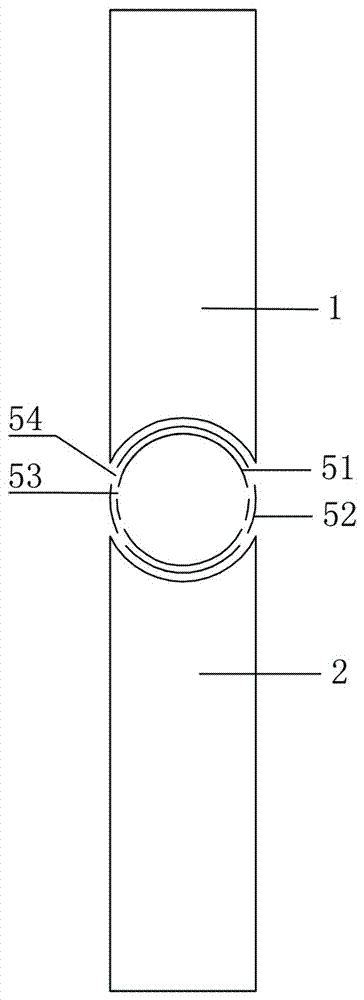

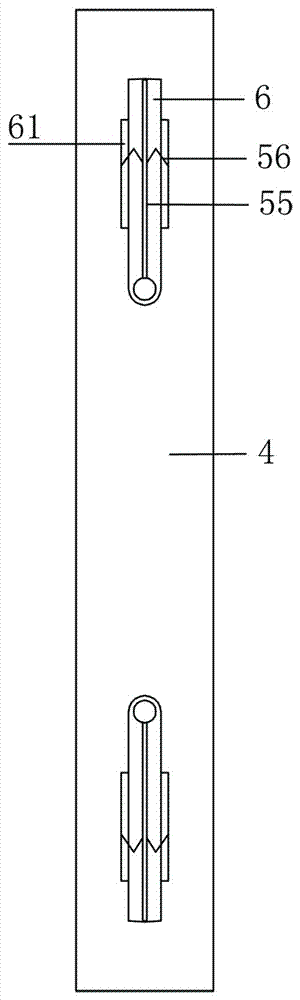

[0028] refer to Figure 5-8 As shown, a wind-resistant protective wall for a construction site in this embodiment includes several repeating units, and each unit includes two first guard plates 1, second guard plates 2, base 3 and two installation columns 4. The base 3 includes a hollow horizontal support rod 31 and a number of hollow longitudinal support rods 32. The horizontal support rod 31 and the longitudinal support rod 32 intersect vertically. The ends of the horizontal support rod 31 and the longitudinal support rod 32 are hinged with a cover plate 33 , the inner surface of the cover plate 33 is provided with a magnetic piece 34, a lead weight 35 is inserted in the horizontal support rod 31 and the longitudinal support rod 32, and the end of the lead weight 35 is fixed with an iron sheet; the bottom ends of the two mounting columns 4 are fixed on the horizontal At both ends of the support rod 31, two first guard plates 1 are symmetrically arranged on the upper and lowe...

Embodiment approach

[0033] As an improved specific embodiment, it also includes a corner assembly, the corner assembly includes a support column 81 and two corner plates 82, the side of the corner plate 82 is hinged on the support column 81, and the other side of the corner plate 82 is connected with The arc-shaped connecting plate 83 is hooped on the outer wall of the mounting column 4 , and the bottom end of the connecting plate 83 is fixed on the transverse support bar 31 . Because the side of the corner plate 82 is hinged on the support column 81, the corner assembly can adapt to the needs of corners of various radians, and the arc-shaped connecting plate 83 is hooped on the outer wall of the installation column 4, so that the installation column 4 can fix the corner assembly. And the connecting plate 83 can be rotated along the mounting column 4 according to the actual rotation angle range.

[0034] As an improved specific embodiment, a third hollow groove 21 is arranged on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com