Device for removing impurities in granular building material

A granular material and garbage technology, which is applied in the field of garbage removal equipment, can solve problems such as low efficiency, decreased overall building safety, and entanglement of mixing devices by garbage, etc., and achieves the effects of convenient use, ensuring building safety, and reducing labor intensity

Inactive Publication Date: 2018-01-16

宁夏博文利奥科技有限公司

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Traditionally, when using granular building materials, it needs to be mixed with water, mixed evenly, and poured or directly filled to make the building stronger. If the interior is doped with impurities such as plastic bags, the Before stirring, if it is found, it will be taken out manually. If it is not found, it will directly enter the stirring device, which will easily cause the stirring device to be entangled with garbage, which will affect the normal operation of the device. The strength of building materials after solidification has a great influence. The weakening of building strength will lead to a decrease in the overall safety of the building. If the internal impurities are manually searched, the strength is relatively high and the efficiency is relatively low. Therefore, in order to solve In these cases, it is necessary to design a device to clean up the garbage inside the granular building materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0025] Embodiment 2: The hydraulic push rod 9 can be replaced by a linear motor and a fixed rod, which can also achieve telescopic effect.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

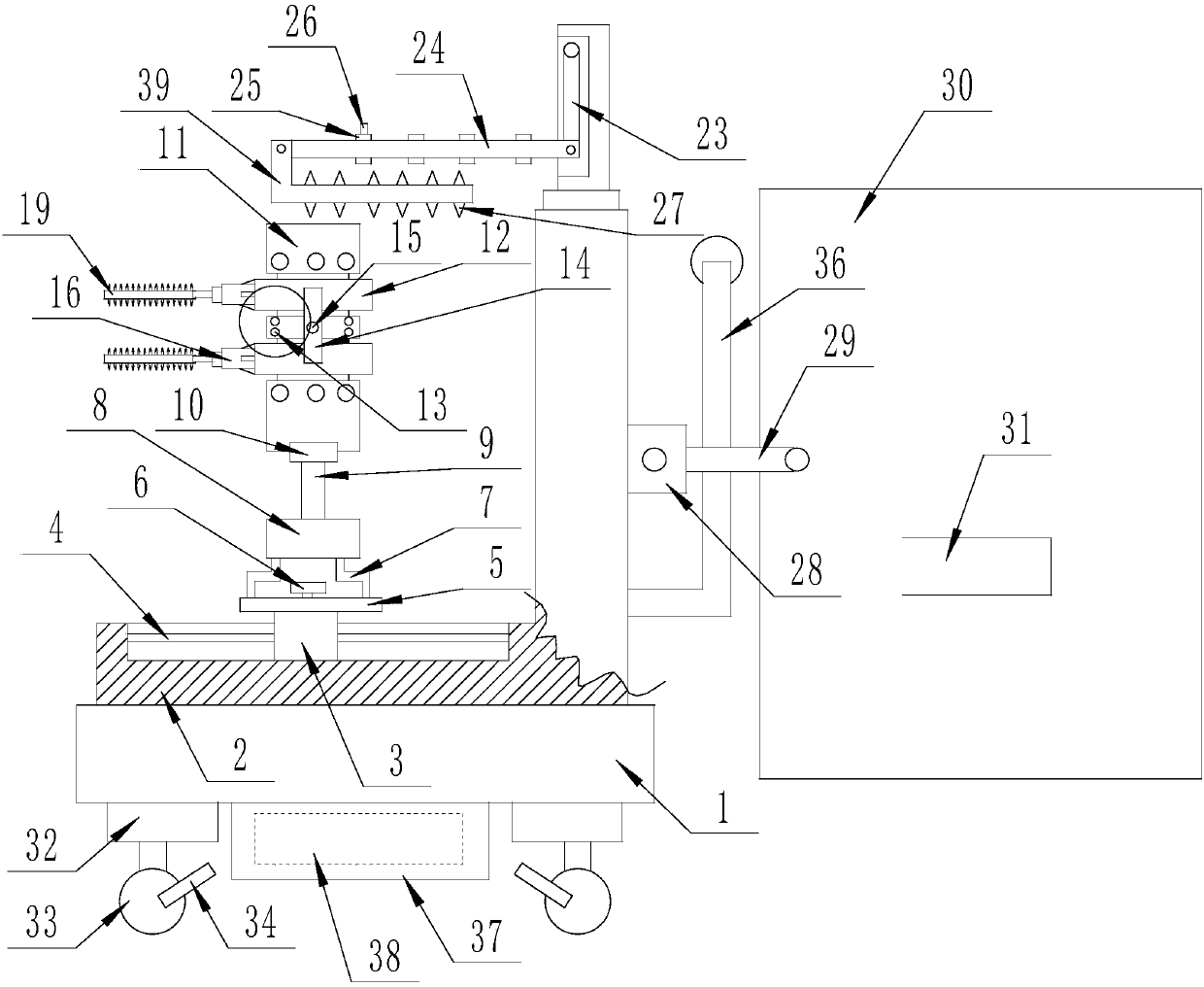

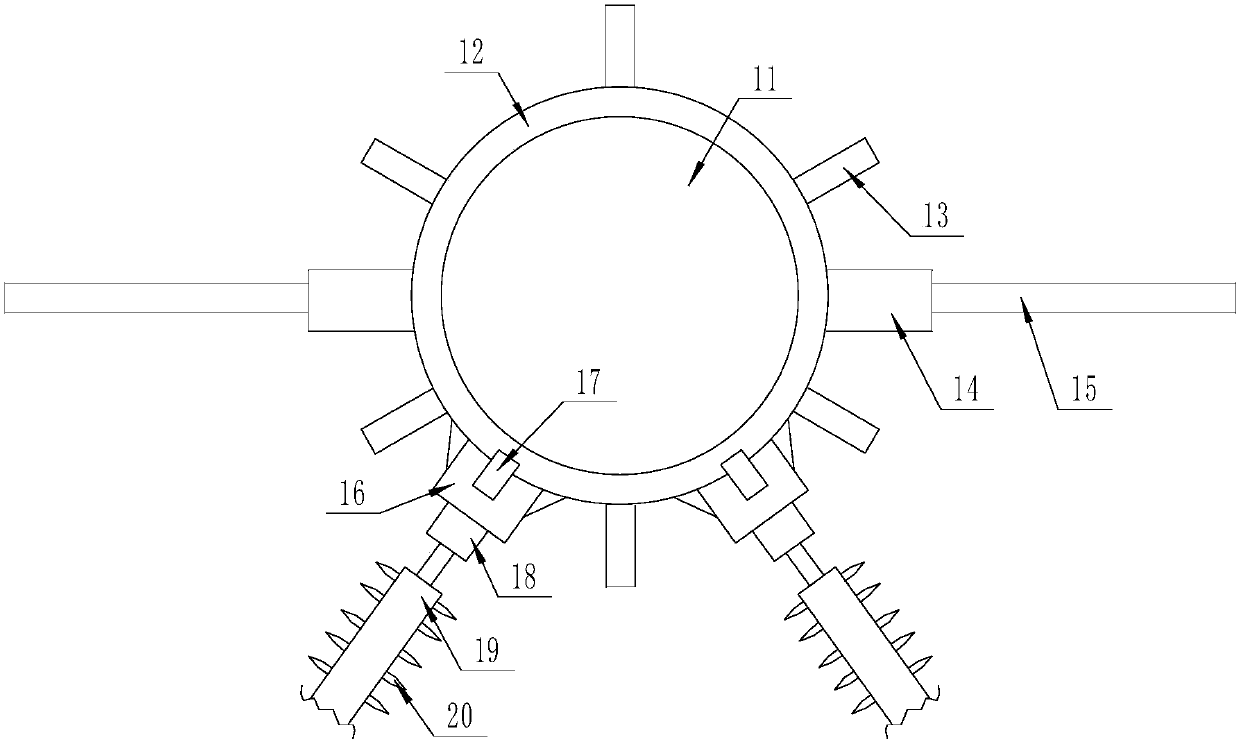

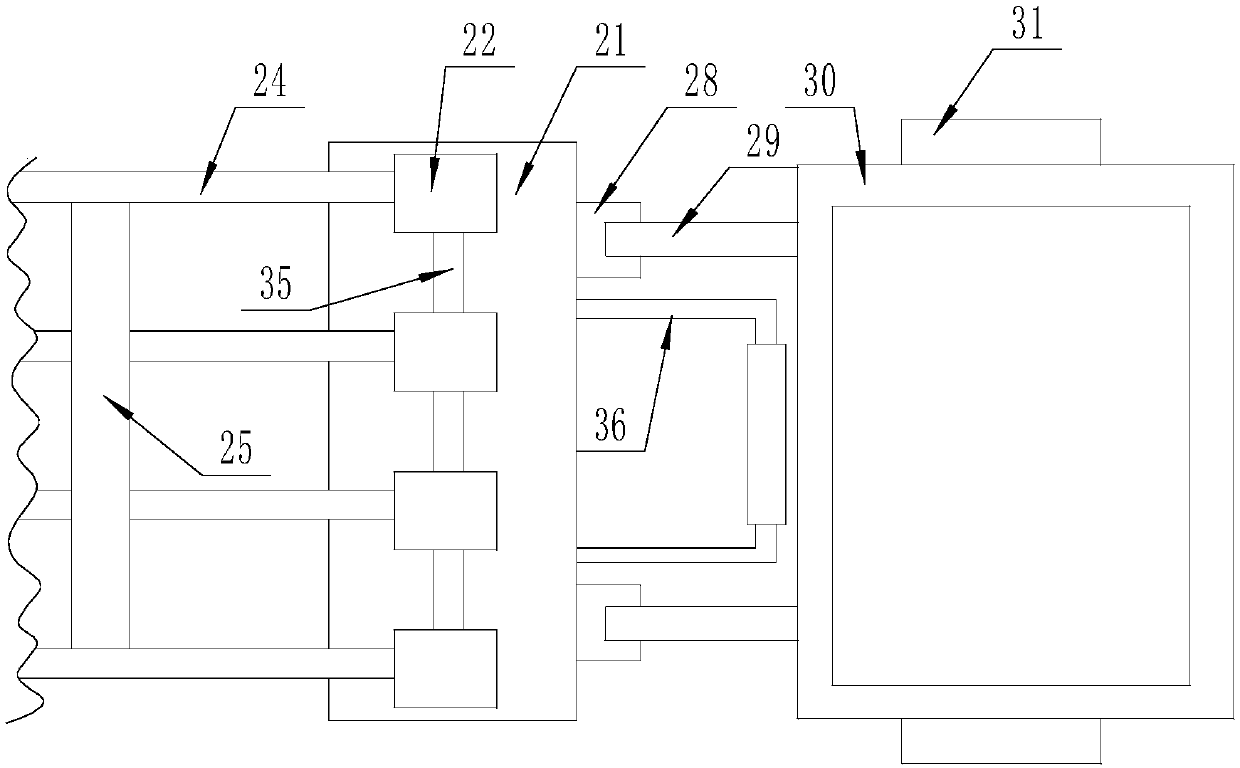

The invention discloses a device for removing impurities in a granular building material. The device comprises a rectangular supporting base, an L-shape fixed supporting plate is fixedly connected tothe upper surface of the rectangular supporting base, a drawing cleaning mechanism is arranged on the upper end face of the L-shape fixed supporting plate, a rotating cleaning mechanism is arranged onthe upper surface face of the L-shape fixed supporting plate, a moving mechanism is arranged on the lower surface of the rectangular supporting base, and a swinging shielding mechanism is arranged onthe outer side surface of the L-shape fixed supporting plate. The device has the advantages of being convenient to use and capable of effectively removing impurities in the granular building material, guaranteeing normal construction, relieving the labor intensity and guaranteeing the safety of a building using the building material.

Description

technical field [0001] The invention relates to the construction field, in particular to a garbage removal device in construction granular materials. Background technique [0002] Granular building materials, such as sand, soil or cement, concrete, are indispensable for construction. [0003] Traditionally, when using granular building materials, it needs to be mixed with water, mixed evenly, and poured or directly filled to make the building stronger. If the interior is doped with impurities such as plastic bags, the Before stirring, if it is found, it will be taken out manually. If it is not found, it will directly enter the stirring device, which will easily cause the stirring device to be entangled with garbage, which will affect the normal operation of the device. The strength of building materials after solidification has a great influence. The weakening of building strength will lead to a decrease in the overall safety of the building. If the internal impurities are ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B07B13/00B07B13/14B28C7/00

Inventor 李珅

Owner 宁夏博文利奥科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com