Patents

Literature

32results about How to "Promote safe building" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

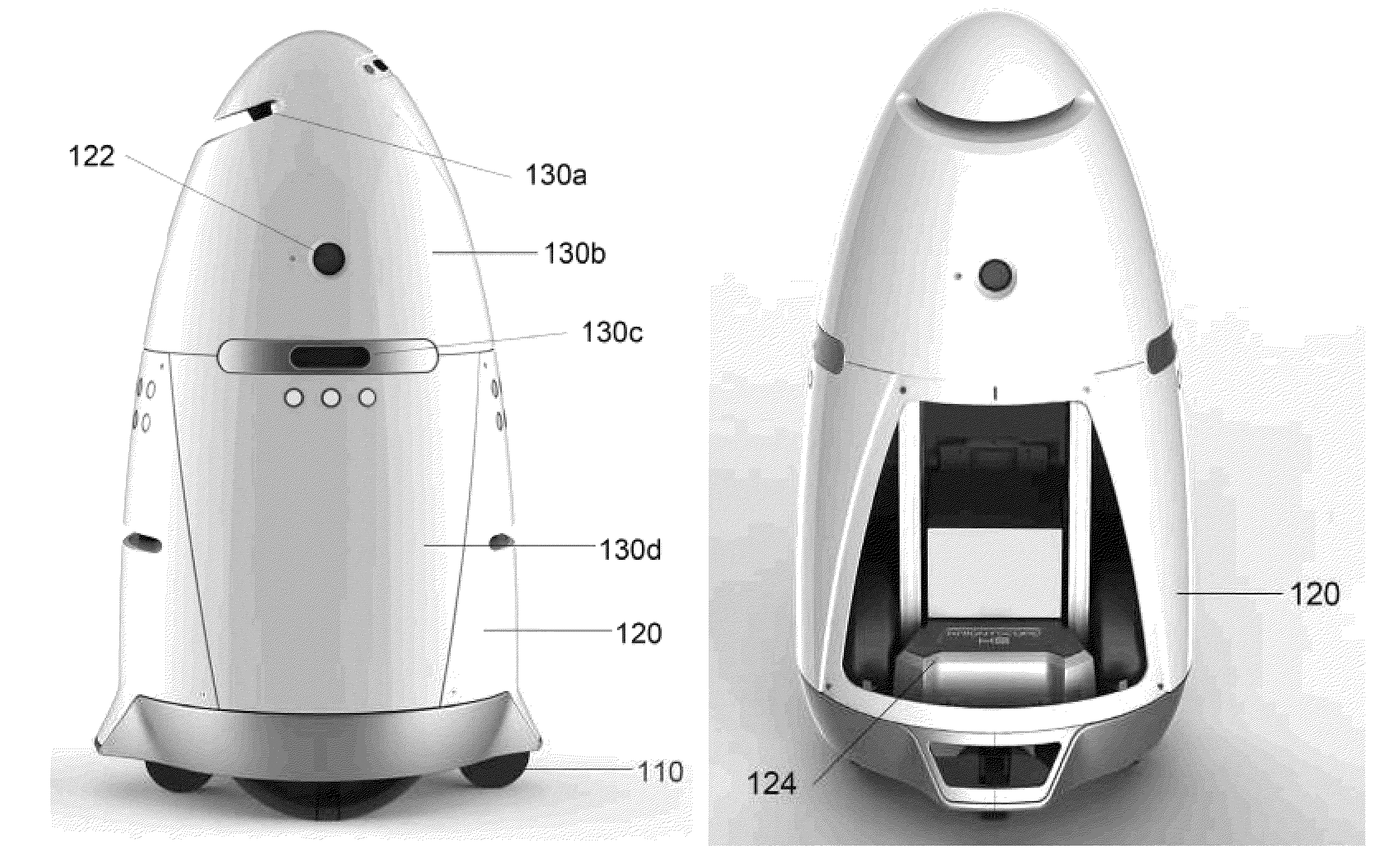

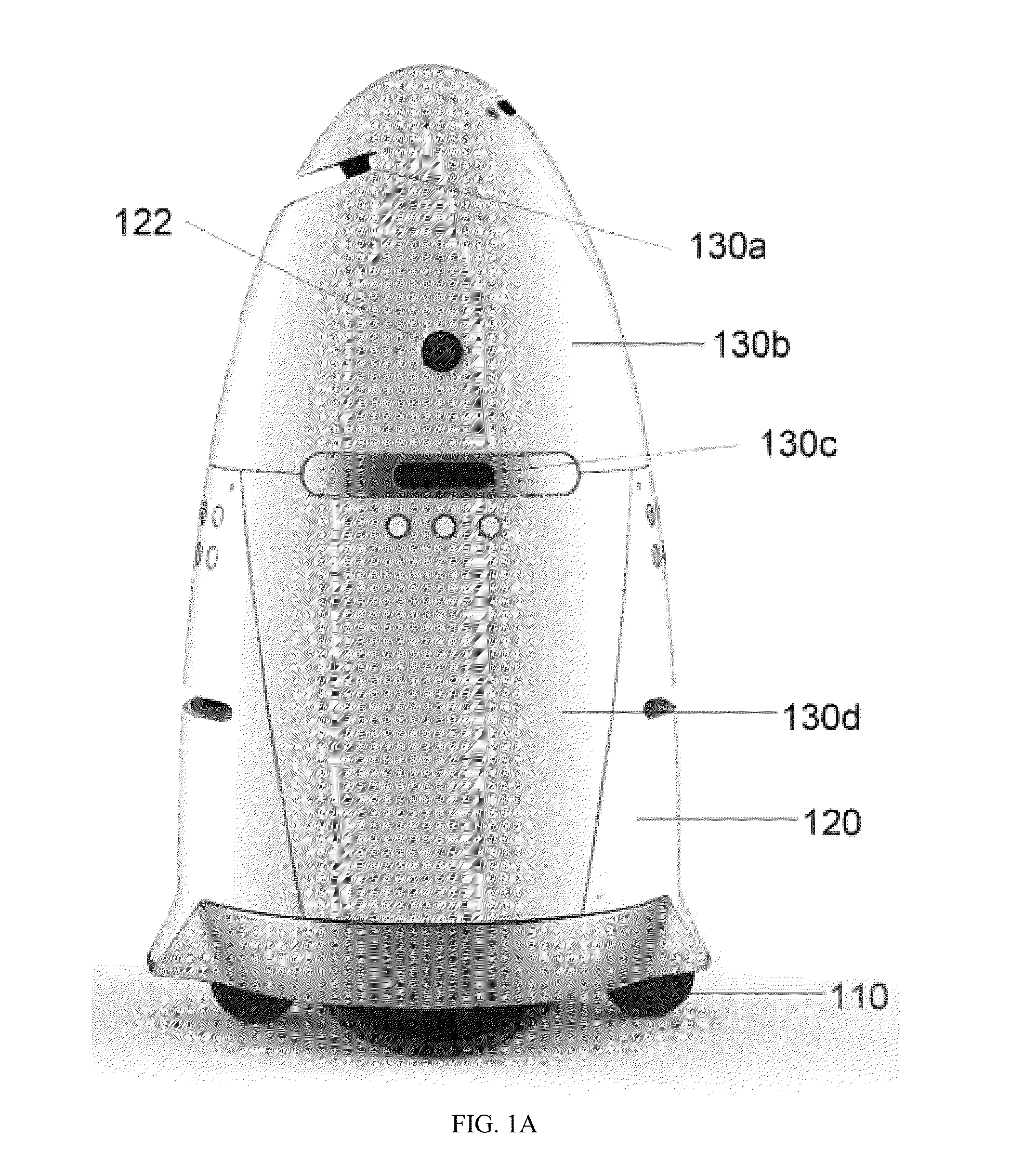

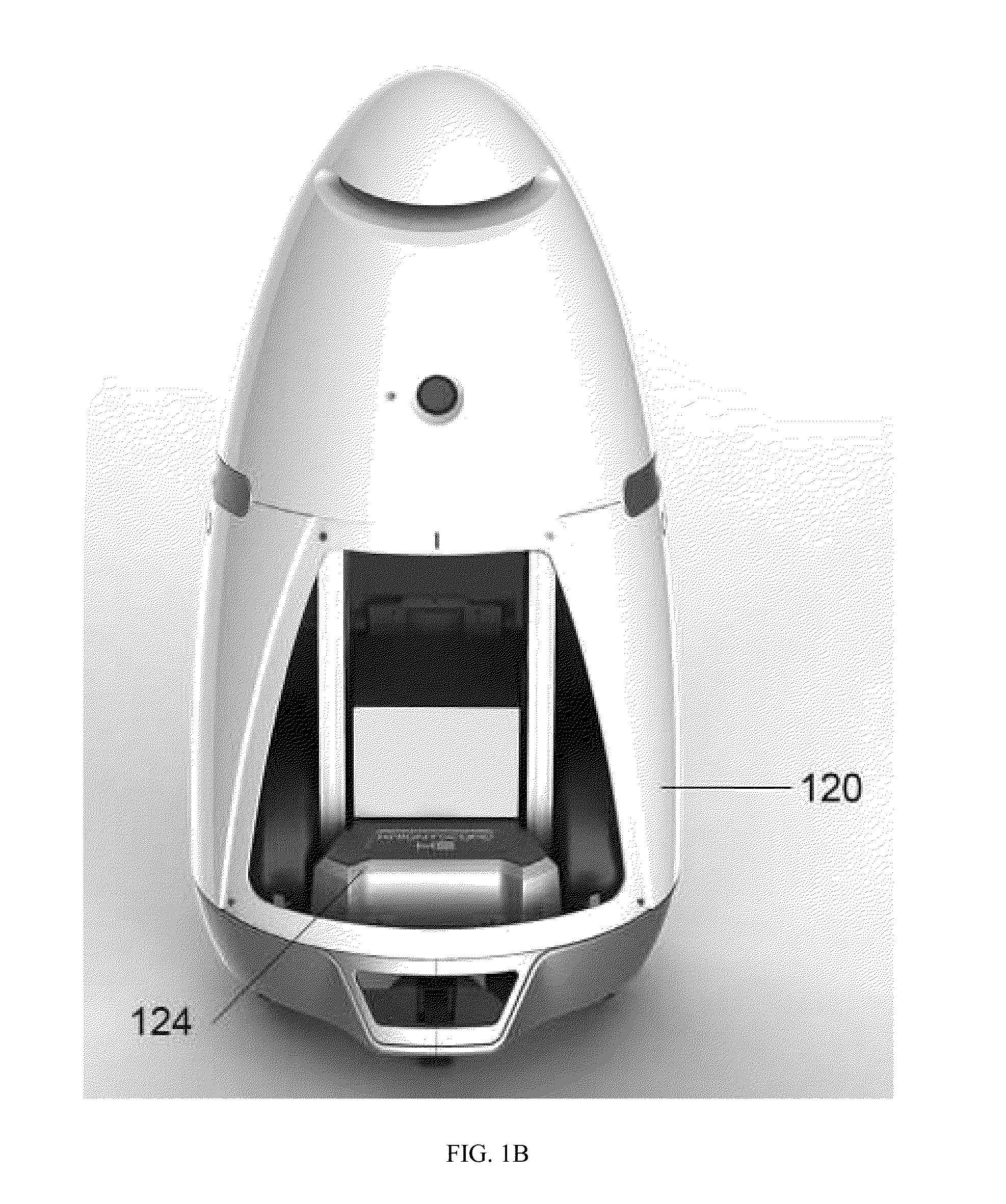

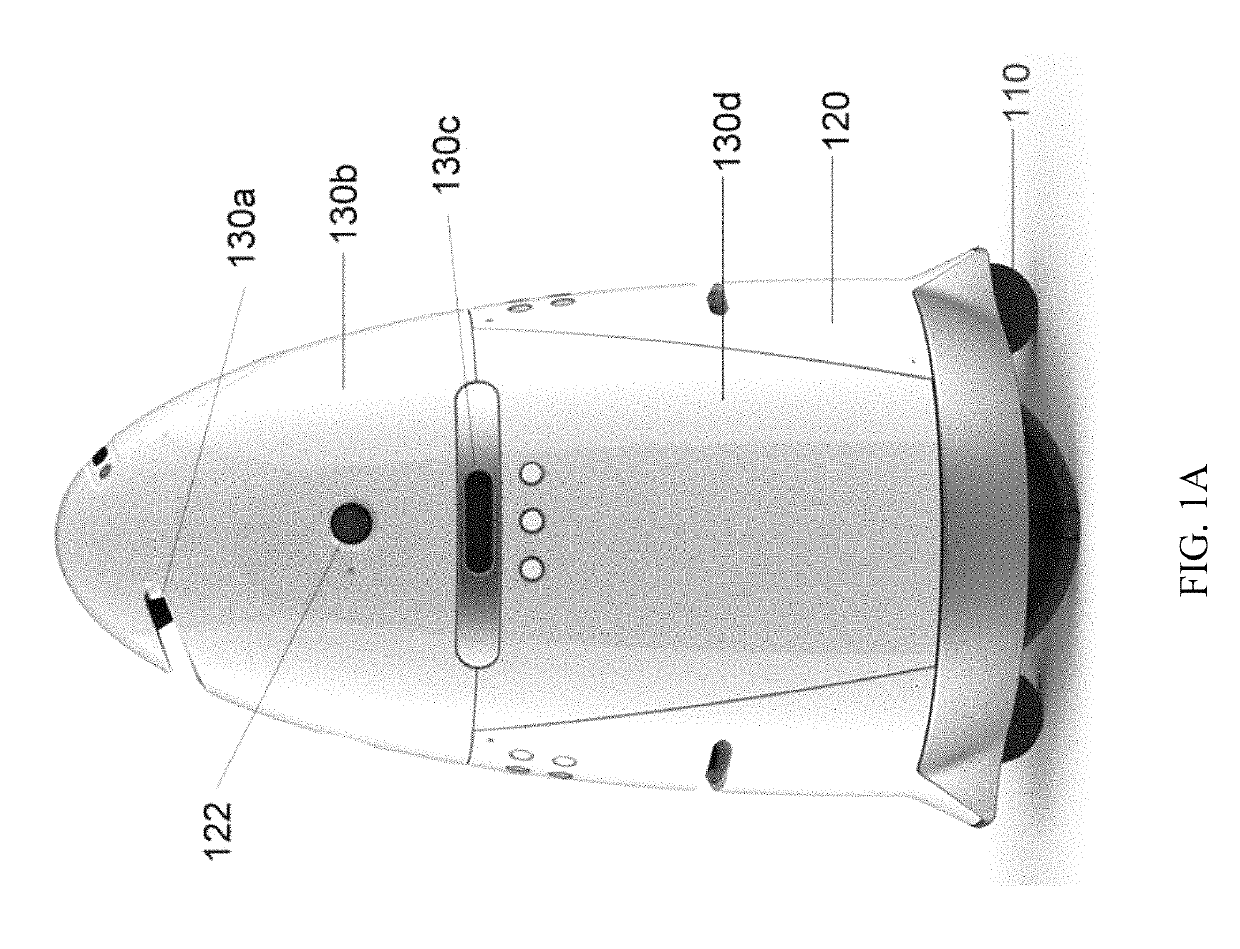

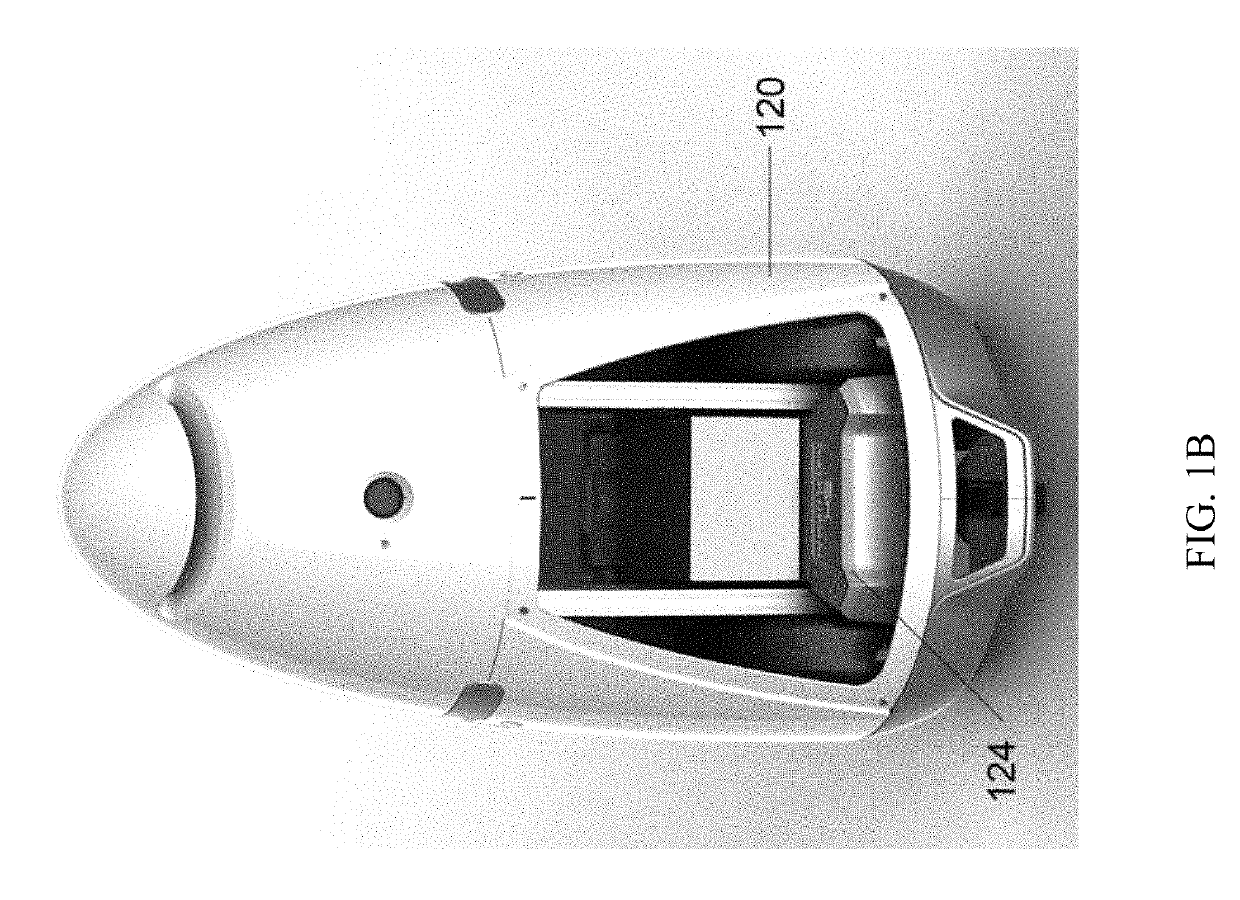

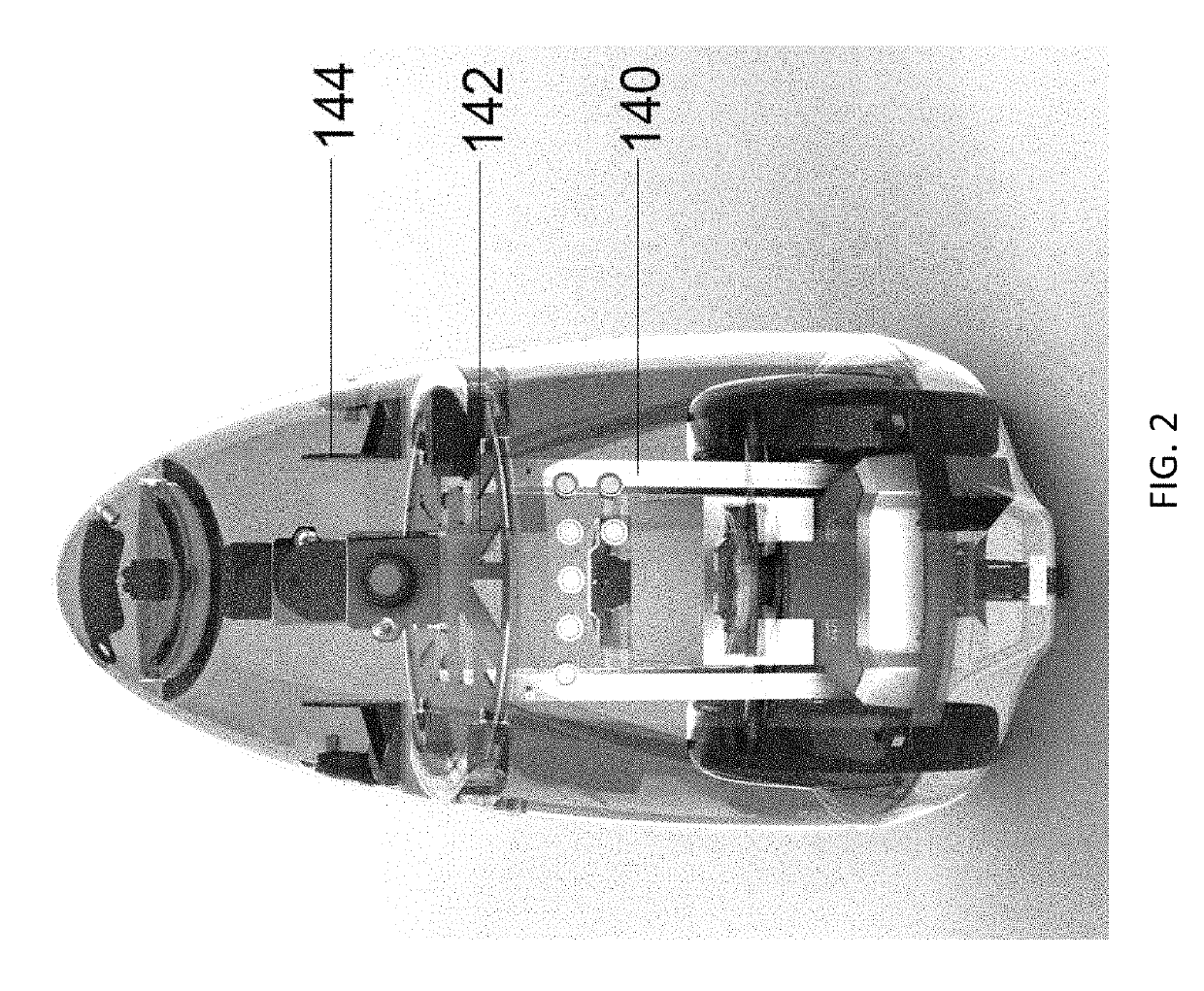

Autonomous data machines and systems

ActiveUS9329597B2Reduce negative personal and economic impactPromote safe buildingAcoustic signal devicesPropulsion by batteries/cellsData sourceData mining

Owner:KNIGHTSCOPE

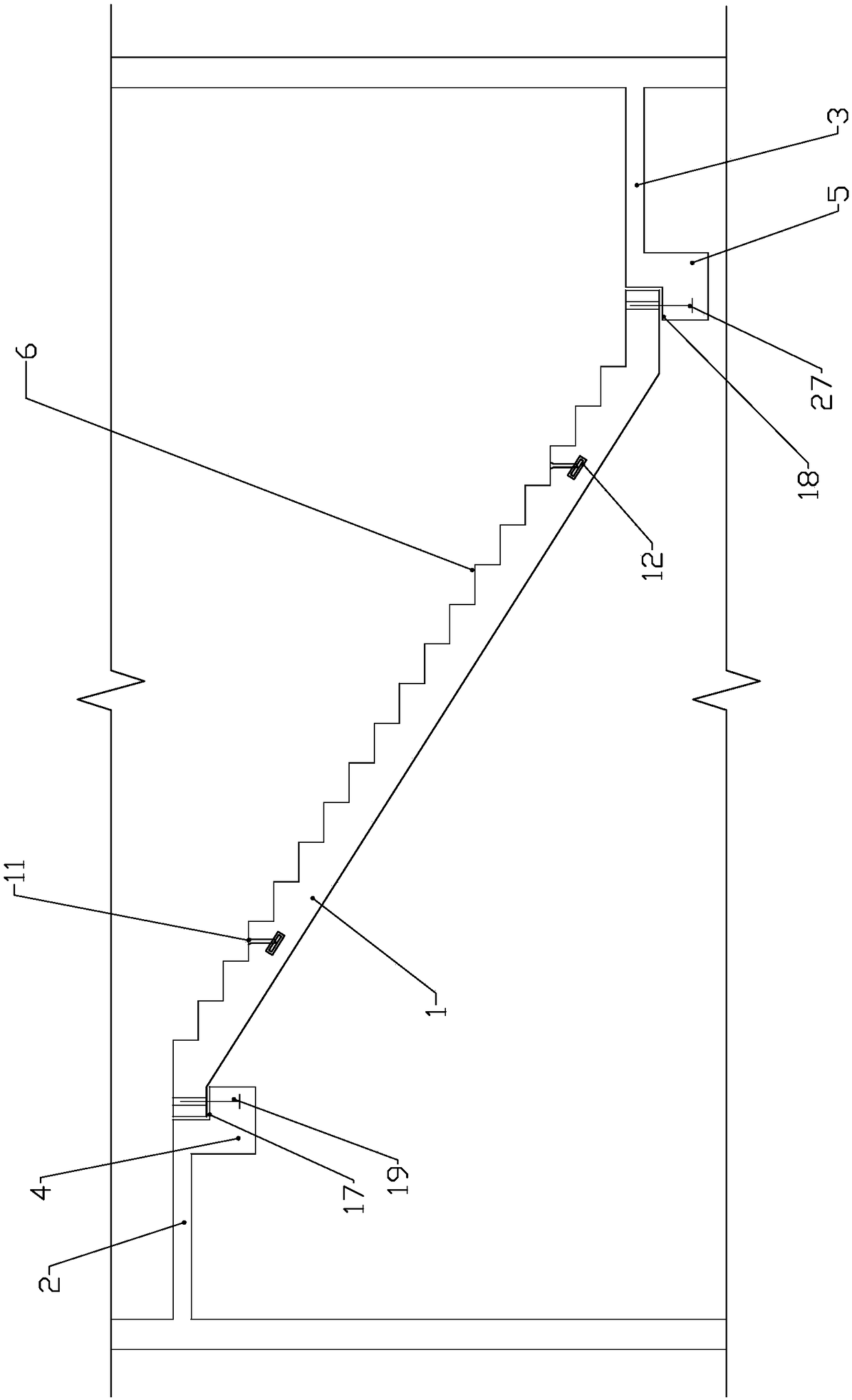

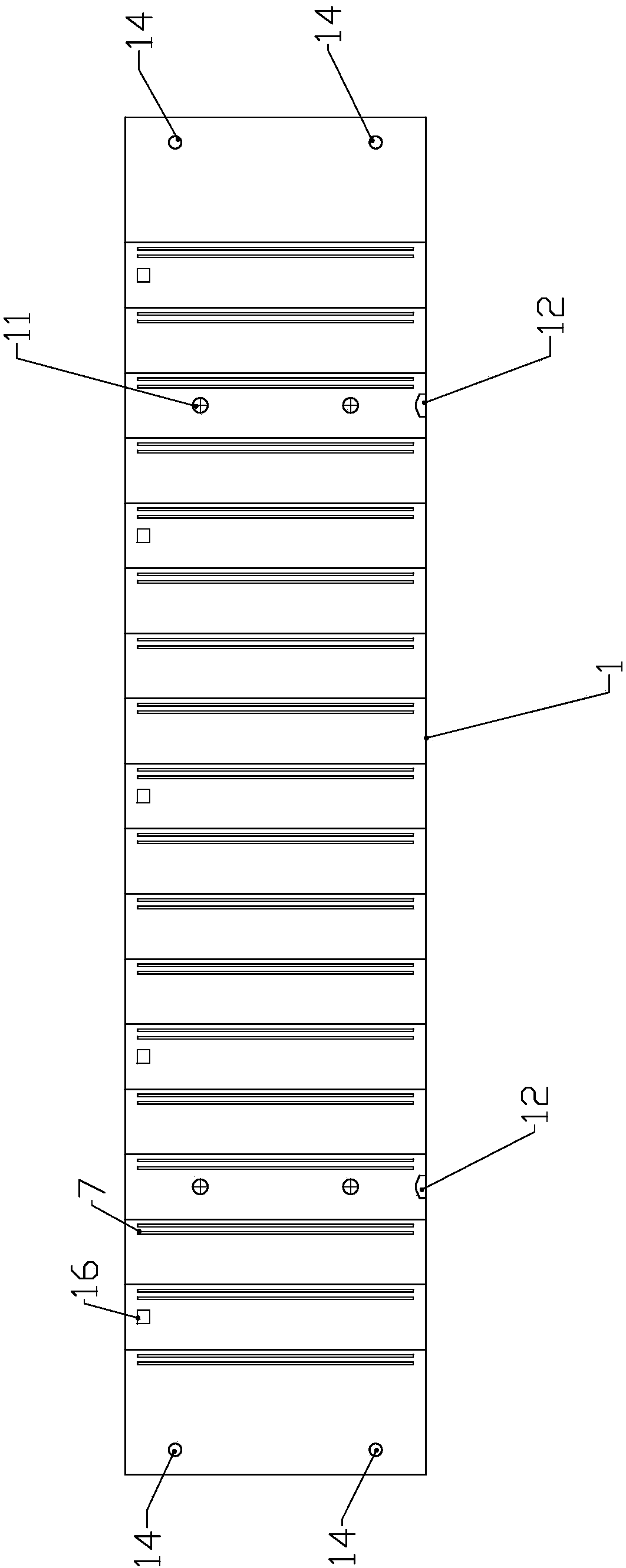

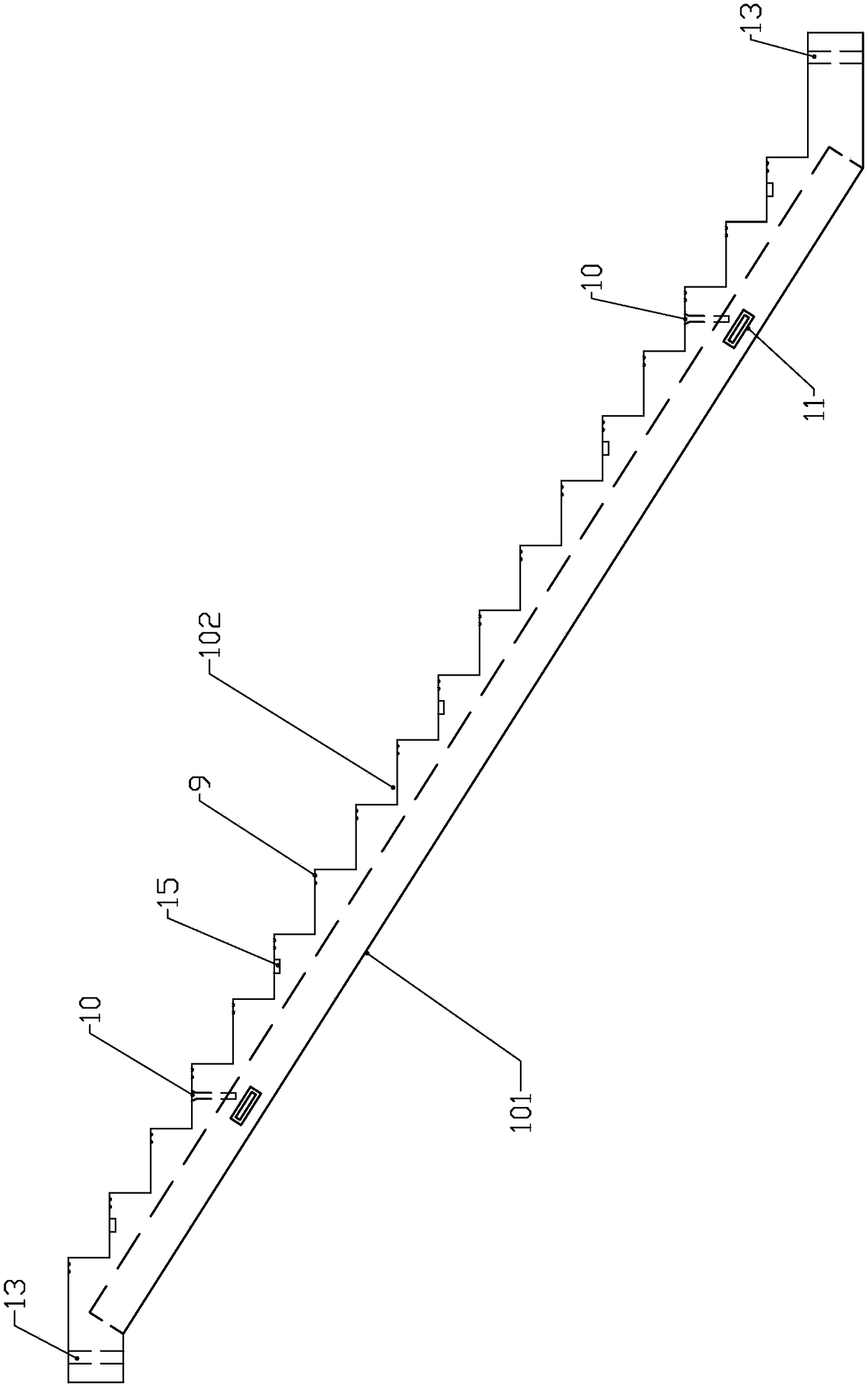

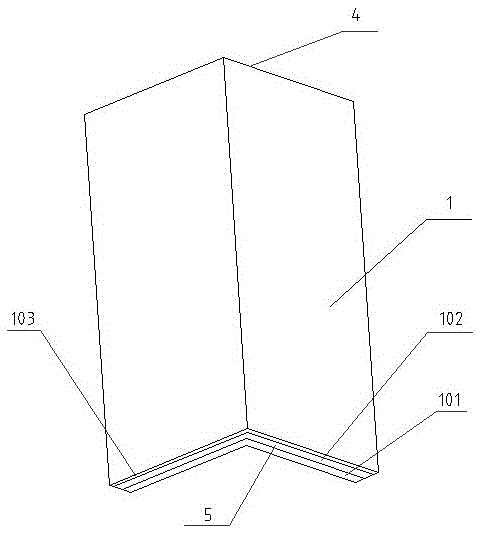

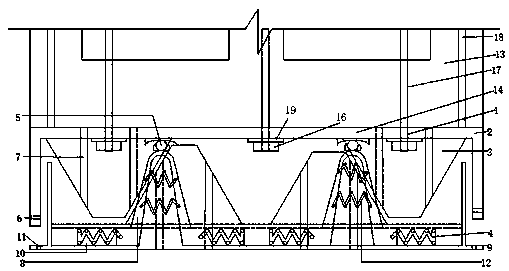

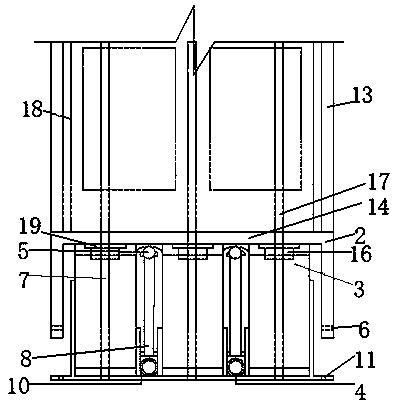

Precast prestressed-concrete slab-type stair and making construction method

PendingCN108166690AReduce transportationReduce the difficulty of hoistingTreadsEarthquake resistanceCrack resistance

The invention discloses a precast prestressed-concrete slab-type stair and a making construction method, and belongs to the technical field of constructional engineering. The precast prestressed-concrete slab-type stair structurally comprises a slab-type stair body aslant arranged, an upper stair platform, a lower stair platform, an upper stair beam and a lower stair beam; the upper stair platformis connected with the upper stair beam, the lower stair platform is connected with the lower stair beam, and the two ends of the slab-type stair body are connected with the upper stair beam and the lower stair beam respectively; ladder-shaped steps are arranged on the slab-type stair body; a prestresed reinforcing steel bar is arranged at the lower portion in the slab-type stair body in the length direction, an upper common reinforcing steel bar is arranged at the upper portion in the slab-type stair body in the length direction, and annular distribution reinforcing steel bars are arranged inthe middle in the slab-type stair body in the length direction at equal intervals, and are located between the prestresed reinforcing steel bar at the lower portion and the upper common reinforcing steel bar at the upper portion. The precast prestressed-concrete slab-type stair and the making construction method have the advantages of being large in application span, good in crack resistance, light in self weight, convenient to hoist and transport, excellent in earthquake resistance and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

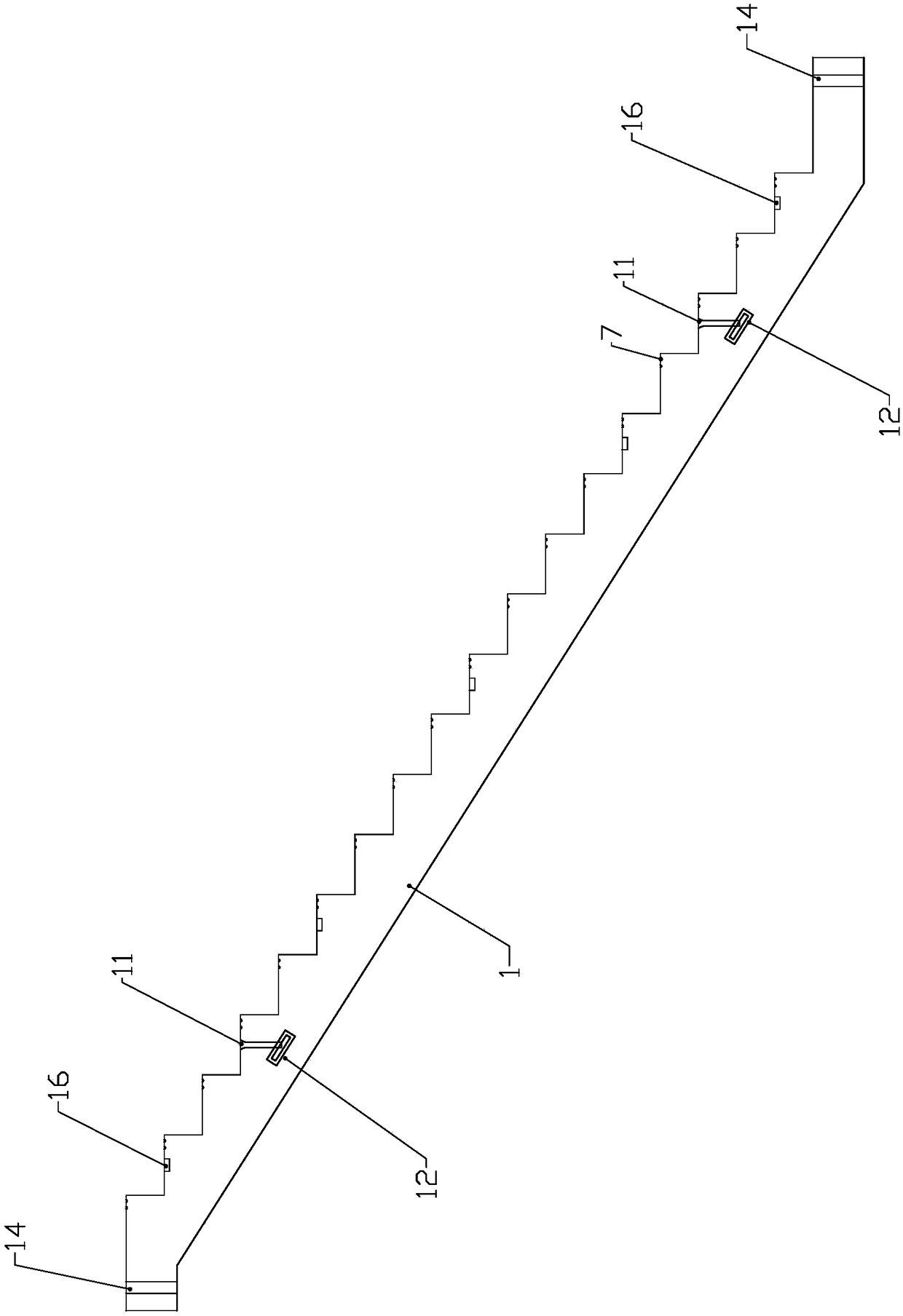

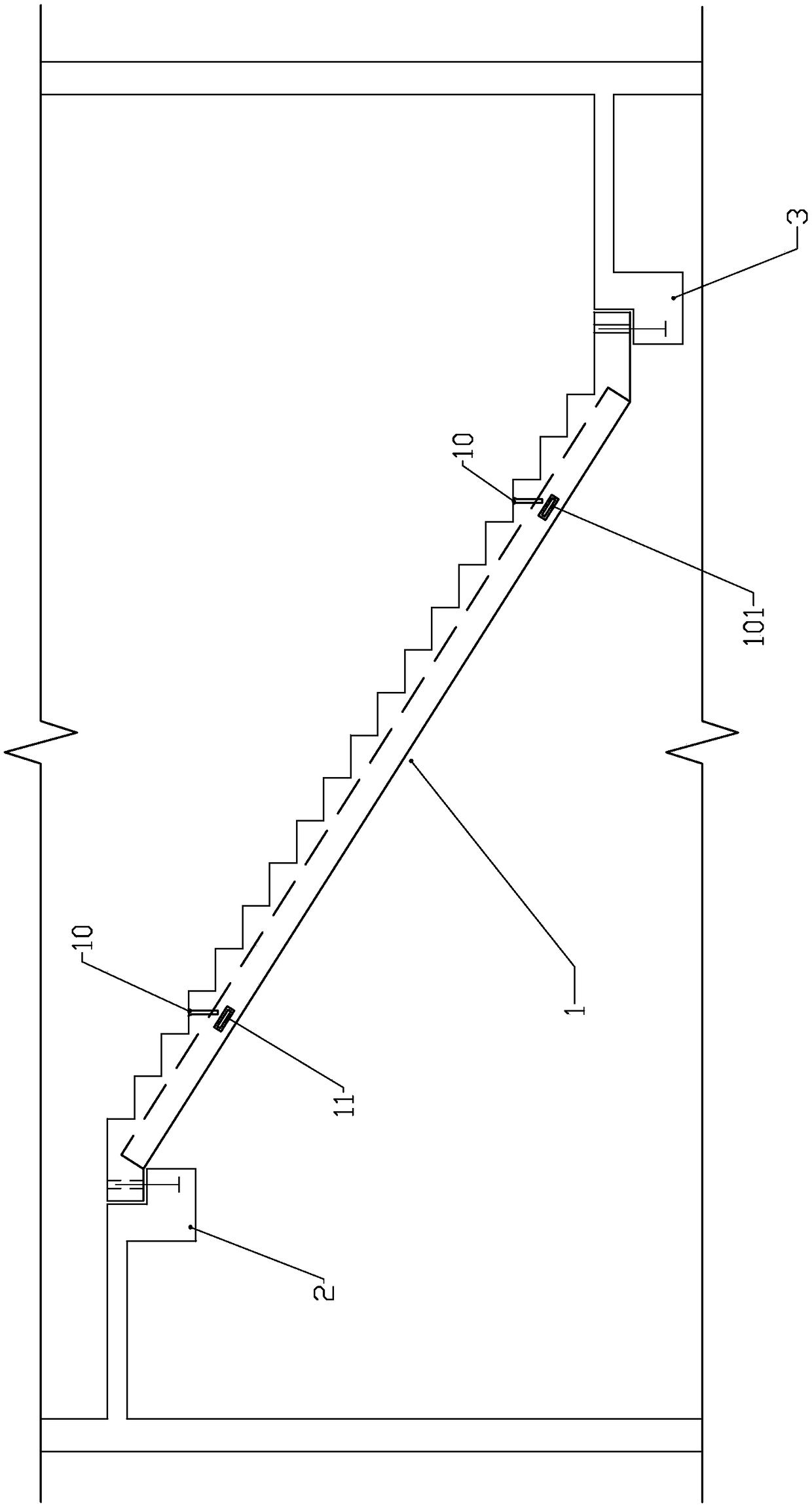

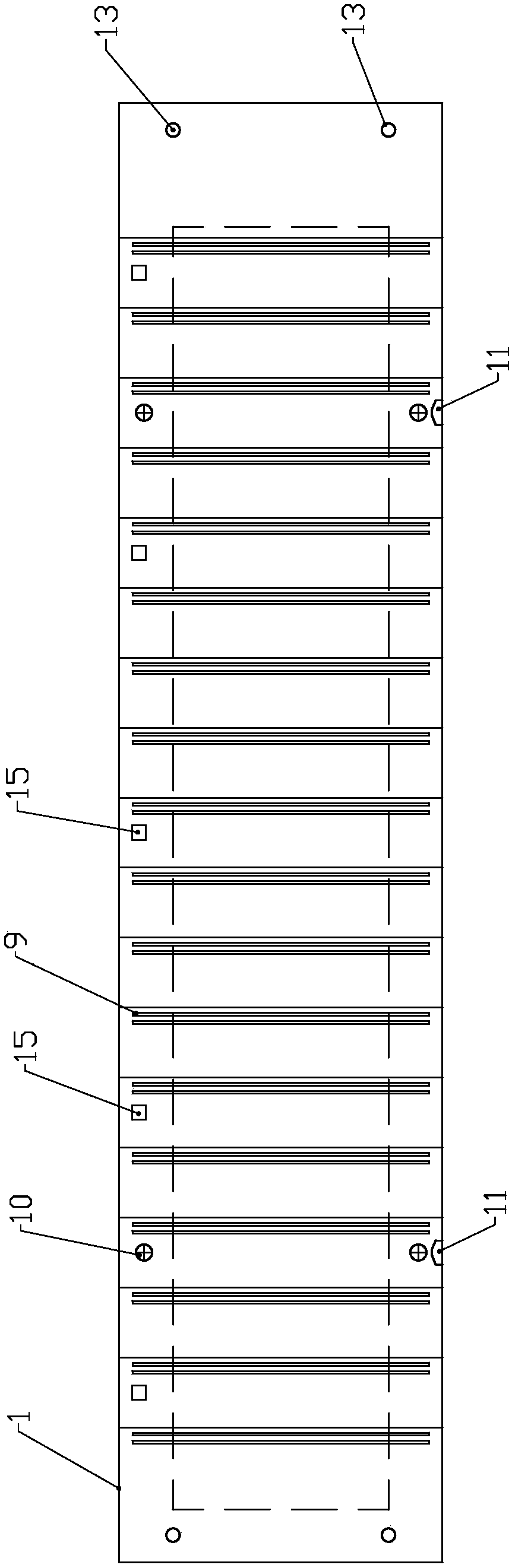

Precast prestresed-concrete beam-type stair and making construction method

PendingCN108166691AReduce difficultyIncreased out-of-plane stiffnessDischarging arrangementMouldsEarthquake resistancePrestressed concrete beam

The invention discloses a precast prestresed-concrete beam-type stair and a making construction method, and belongs to the technical field of constructional engineering. The precast prestresed-concrete beam-type stair structurally comprises a beam-type stair body, an upper stair beam and a lower stair beam, wherein the upper stair beam and the lower stair beam are used for supporting the beam-typestair body; the beam-type stair body comprises a stair-section slant beam and ladder-shaped steps, the stair-section slant beam is arranged in the length direction of the beam-type stair body, the two ends of the steps are supported on the stair-section slant beam, the two ends of beam-type stair body are connected with the upper stair beam and the lower stair beam respectively, a prestresed reinforcing steel bar is arranged at the lower portion of the stair-section slant beam in the length direction, an upper common reinforcing steel bar is arranged at the upper portion of the stair-sectionslant beam in the length direction, stirrups are arranged outside the prestresed reinforcing steel bar and the upper common reinforcing steel bar in the length direction at equal intervals, the prestresed reinforcing steel bar and the upper common reinforcing steel bar are located in the stirrups, and step distribution reinforcing steel bars are arranged in the steps. The precast prestresed-concrete beam-type stair and the making construction method have the advantages of being large in application span, good in crack resistance, light in self weight, convenient to hoist and transport, excellent in earthquake resistance and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Energy-saving and environment-friendly brick and preparation method

The invention discloses an energy-saving and environment-friendly brick and a preparation method. A brick body comprises cement, fly ash, waste plastics, waste fiber, plant straw, river bottom sludge, calcium carbonate, glass microbeads, quartz powder, wood chips and high-adhesion attapulgite clay. The preparation method comprises the steps of evenly mixing the cement, the fly ash, the river bottom sludge, the calcium carbonate and the quartz powder, adding the smashed waste plastics, waste fiber, plant straw and the wood chips and performing uniform mixing, adding water and performing mixing; adding the glass microbeads, the quartz powder and the high-adhesion attapulgite clay, and perform uniform mixing; forming the mixture, placing the mixture in a steam curing system for steam curing, and obtaining the energy-saving and environment-friendly brick. The energy-saving and environment-friendly brick has the advantages of being low in manufacturing cost and light in mass. Waste materials are adopted to replace soil sand and pebbles and the like, environmental disruption caused by overexploitation is avoided, waste reutilization is implemented, and the brick body further has good effects of water prevention and heat insulation.

Owner:合肥永泰新型建材有限公司

Construction method of plant community in South China

InactiveCN101836572AScientific control of seeding rateReduced safety builtSeed and root treatmentForestryPlant communityPlanting seed

The invention provides a construction method of plant community in South China, comprising the following steps of selecting plant seeds of grasses, shrub and arbor; treating a part of the seeds; preparing a seed mixture; preparing a substrate mixture; preparing a seed and substrate mixture; jetting the seed and substrate mixture; controlling the herb height and the density of the shrub and the arbor; spraying paclobutrazol physic liquor to herbs; spraying stress resistant high nutrition foliar fertilizer to the arbor; and finally, carrying out conventional management. The invention can promote the seeds to fast and safely germinate, guarantee stable structure and function of artificial vegetation, and efficiently shorten the succession period from the artificial vegetation to natural vegetation, and is used for the construction method of geotechnical wound surfaces including slopes, abandoned dreg sites and mining places and plant communities of degraded soils in the South China.

Owner:SICHUAN UNIV

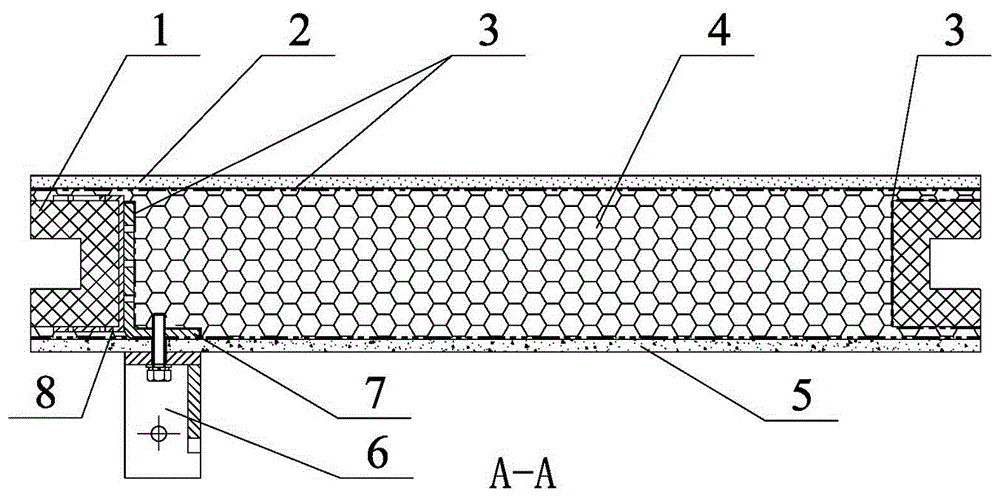

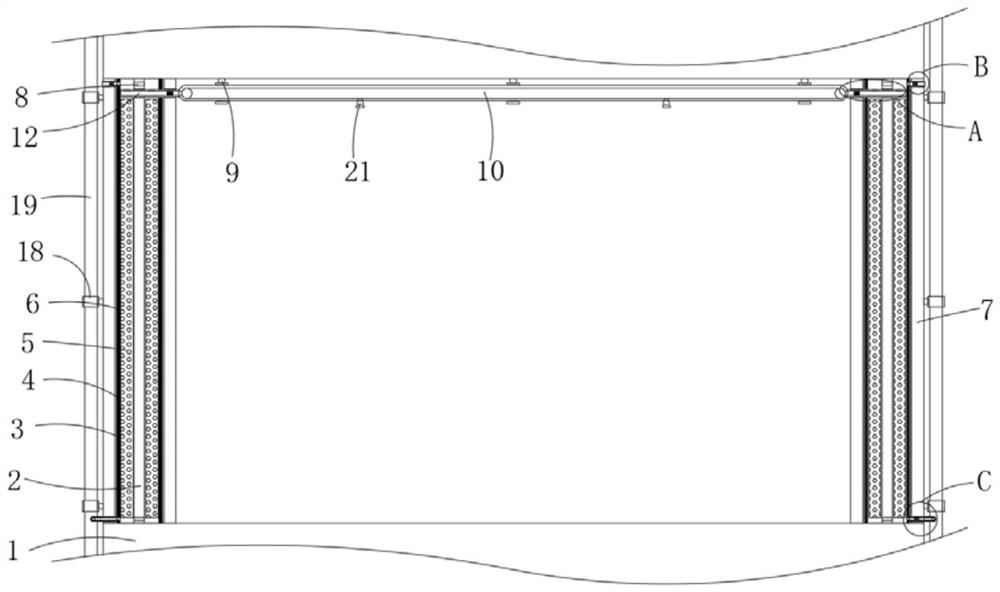

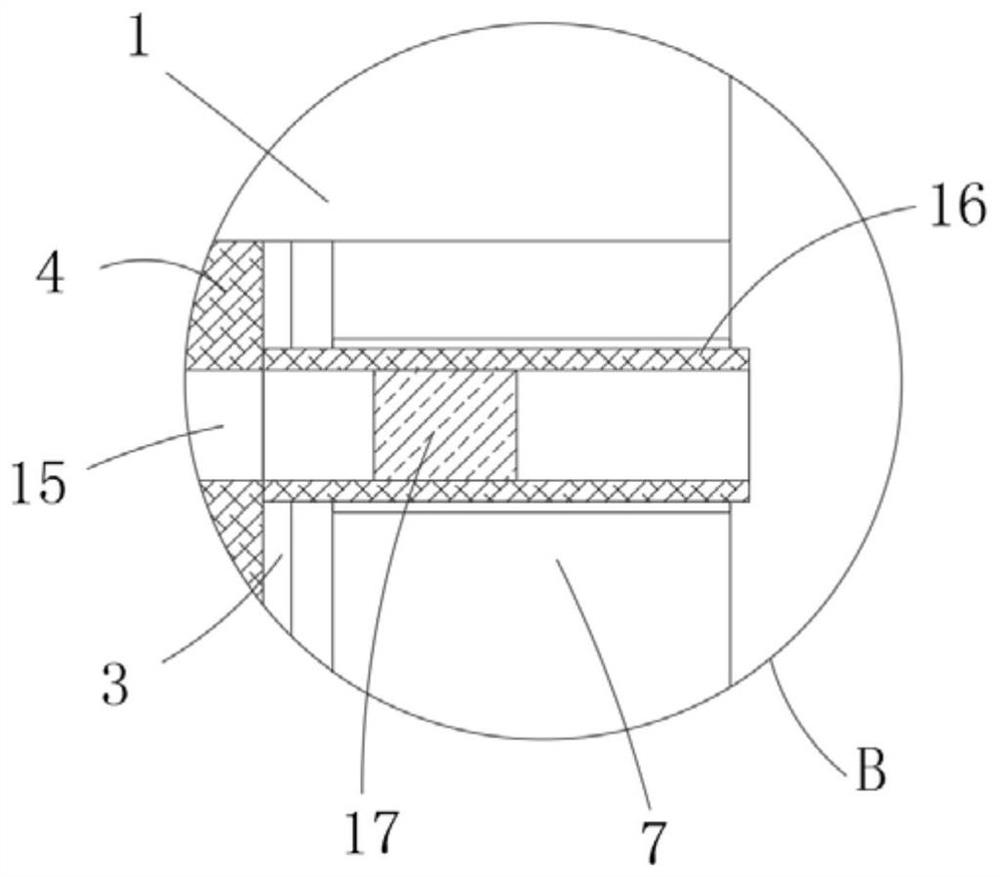

Unit curtain wall of composite bearing structure

InactiveCN104594535AReduce mechanical performance requirementsReasonable forceWallsSkin effectEngineering

A unit curtain wall of a composite bearing structure solves the problems that high-rigidity panels of an existing curtain wall of a frame supporting system do not share wind loads and consequently construction cost is high and construction energy consumption is large. The unit curtain wall comprises unit plates and connecting assemblies for assembling the unit plates and a building main body, and is technically characterized in that according to each unit plate, an inner panel, an outer panel and a frame with a port are combined through core materials and bonding layers to form an integrated structure with a skin effect; each connecting assembly comprises a plate inner embedded part, a plate connecting part, a main body structure connecting part, a sealing rubber strip and a plate insertion positioning block or a plate insertion positioning frame, and the two ends of each main body structure connecting part are fixedly connected with the corresponding plate connecting part and a building main body structure. The composite bearing structure design is adopted, the plates of the curtain wall bear force more reasonably, and the materials are utilized more sufficiently; on the basis of guaranteeing construction safety and decoration effects, the materials are further saved, the construction cost and energy consumption of the curtain wall are reduced, and diversified demands of construction effects are met.

Owner:上海易旋建筑设计咨询有限公司

Construction method of plant community in Central China

InactiveCN101836544AImprove germination rateScientific control of seeding rateForestryPlant protectionPlant communityPlanting seed

The invention provides a construction method of plant community in Central China, comprising the following steps of selecting plant seeds; pretreating a part of the seeds; preparing a seed mixture; preparing a substrate mixture; preparing a seed and substrate mixture; jetting the seed and substrate mixture; controlling the herb height and the density of shrub and arbor; spraying paclobutrazol physic liquor to herbs; spraying stress resistant high nutrition foliar fertilizer to the arbor; and carrying out conventional management. The invention can promote the seeds to fast and safely germinate, guarantee stable structure and function of artificial vegetation, and efficiently shorten the succession period from the artificial vegetation to natural vegetation, and is used for constructing geotechnical wound surfaces including slopes, abandoned dreg sites and mining places and plant communities of degraded soils in Central China.

Owner:SICHUAN UNIV

Autonomous data machines and systems

ActiveUS10279488B2Reduce negative personal and economic impactPromote safe buildingBatteries circuit arrangementsVehicular energy storageEngineeringCharging station

A charging system for an autonomous data machine may be provided. The system may comprise: a charging station, wherein the charging station has a low profile allowing the autonomous data machine to drive over to charge a power supply of the autonomous data machine automatically; and one or more processors of the autonomous data machine configured to make charging decisions to effect charging operations of the autonomous data machine that include charging time, charging location, and operations to be performed during charging. In some instances, the charging decision are based on at least one of the following: location of charging station, availability of charging station, mission parameters, locations of other autonomous data machines, and / or charging requirements and / or availability of charging stations.

Owner:KNIGHTSCOPE

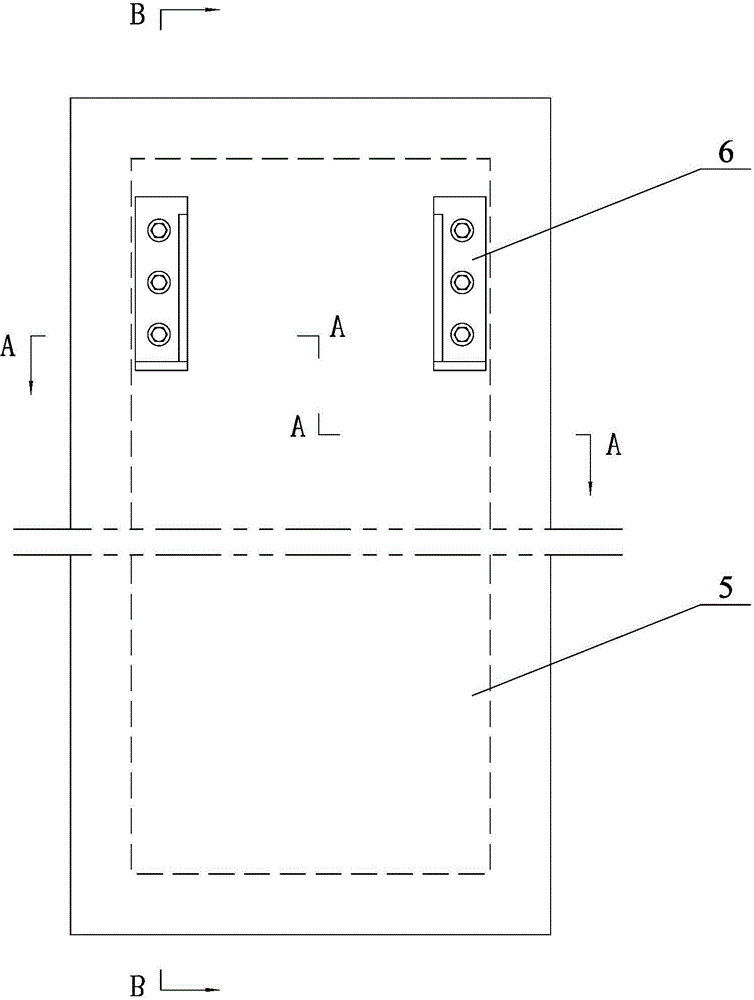

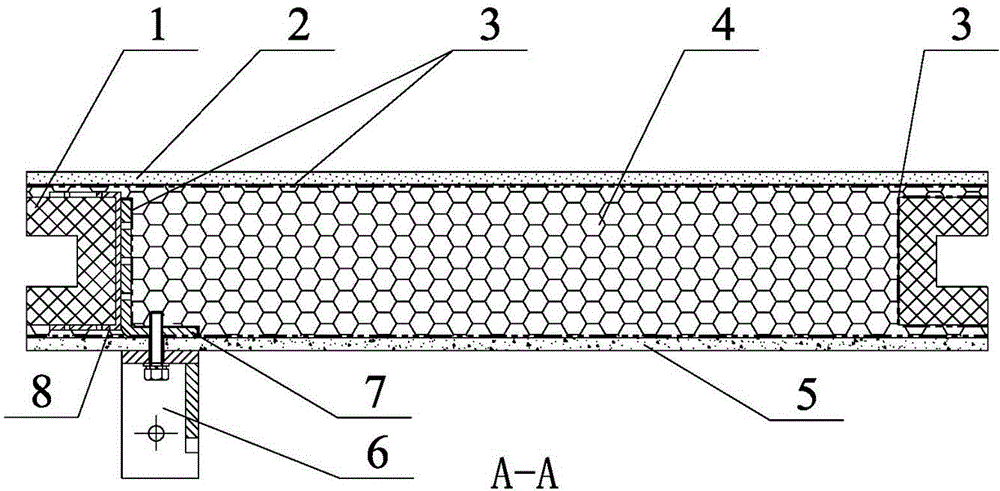

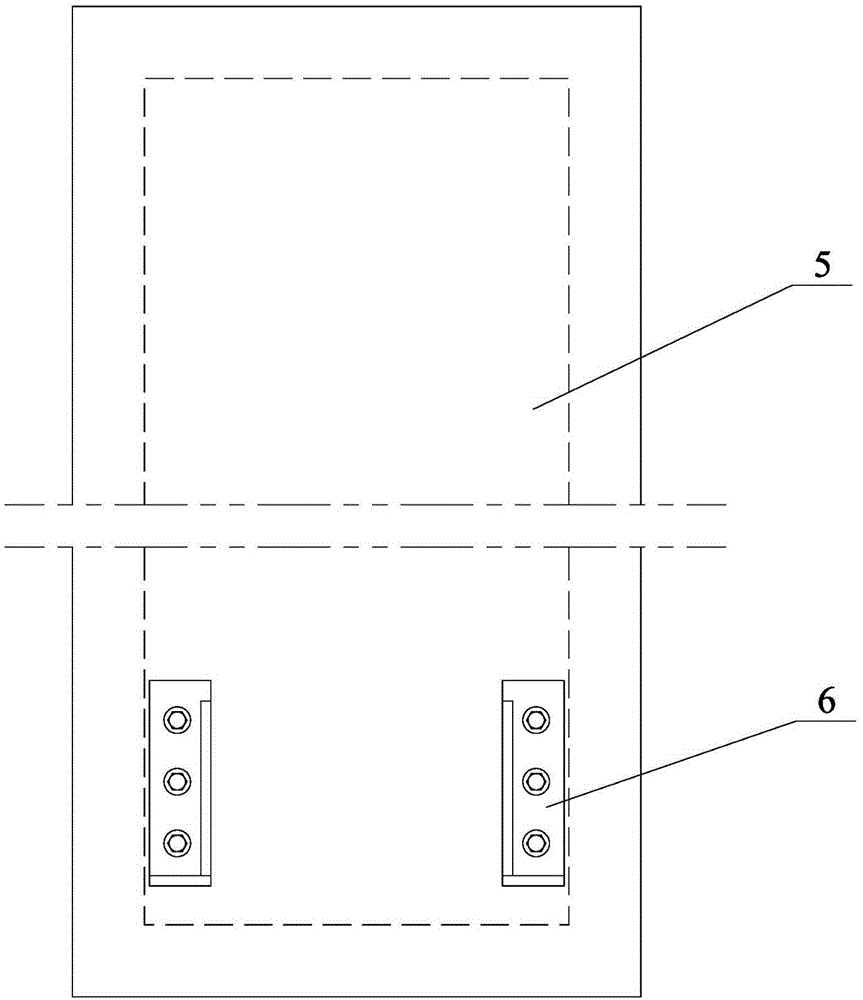

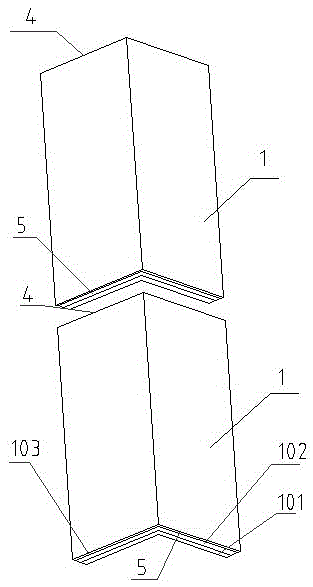

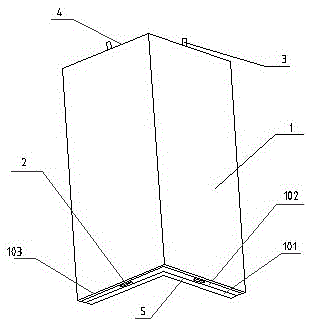

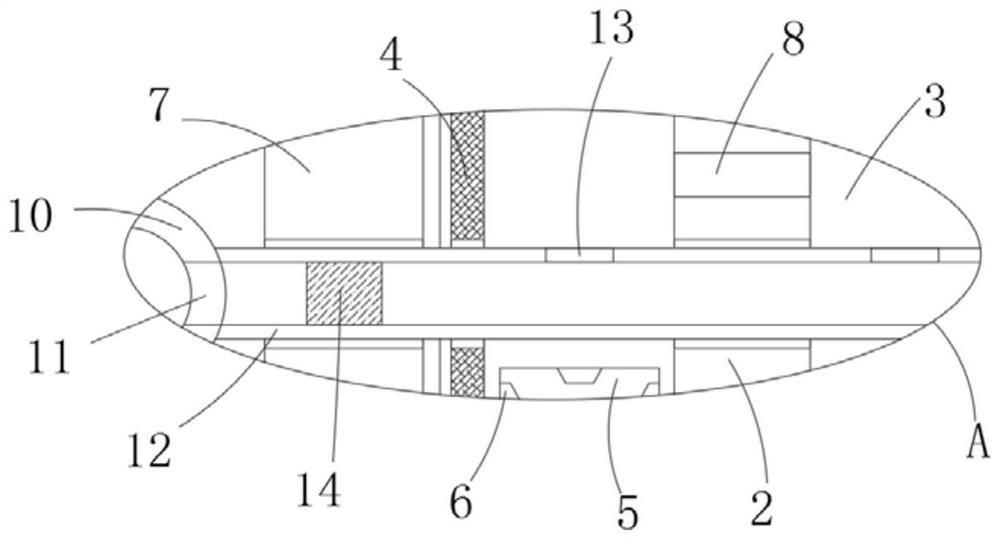

PCF board fixing device and installing method

InactiveCN105544996AQuick placementGuaranteed verticalityBuilding material handlingConstruction engineeringEconomic benefits

The invention relates to the technical field of building construction, in particular to a PCF board fixing device. The PCF board fixing device comprises a PCF board and further comprises a positioning hole formed in the upper installing end face of the PCF board and a positioning shaft arranged on the lower installing end face of the PCF board. The positioning hole and the positioning shaft are arranged in a matched mode. Due to the fact that the PCF board is provided with the positioning hole and the positioning shaft, the problem that the PCF board is difficult to place is effectively solved, the problem that the PCF board needs to be adjusted for the second time, and accordingly construction progress and building quality are affected is also solved, the PCF board can be fast and conveniently positioned and fixed, construction progress is substantially accelerated, lots of time and manpower are saved, there are large influences on increase of economic benefits, meanwhile, building quality is improved, and safety of a building is guaranteed.

Owner:CHENGDU SIXTH CONSTR ENG

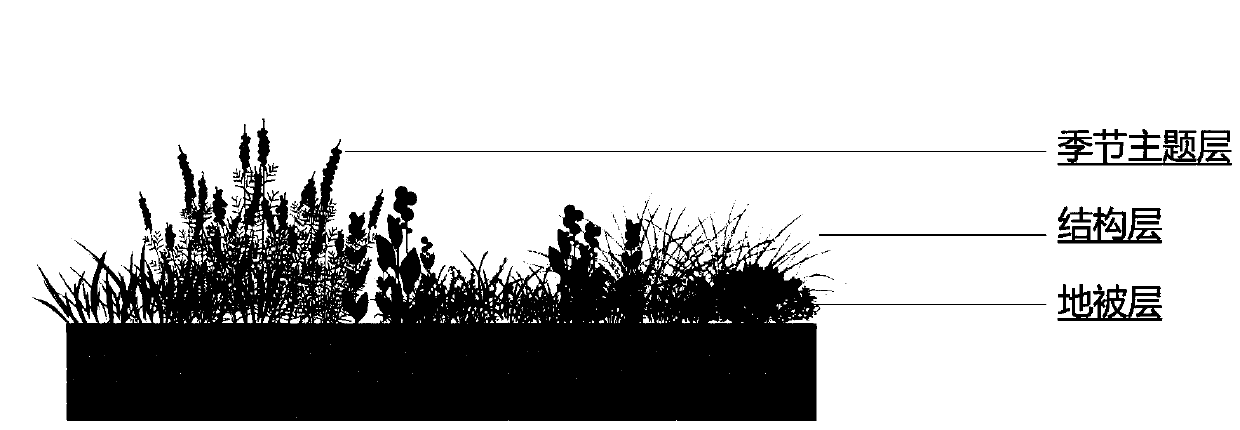

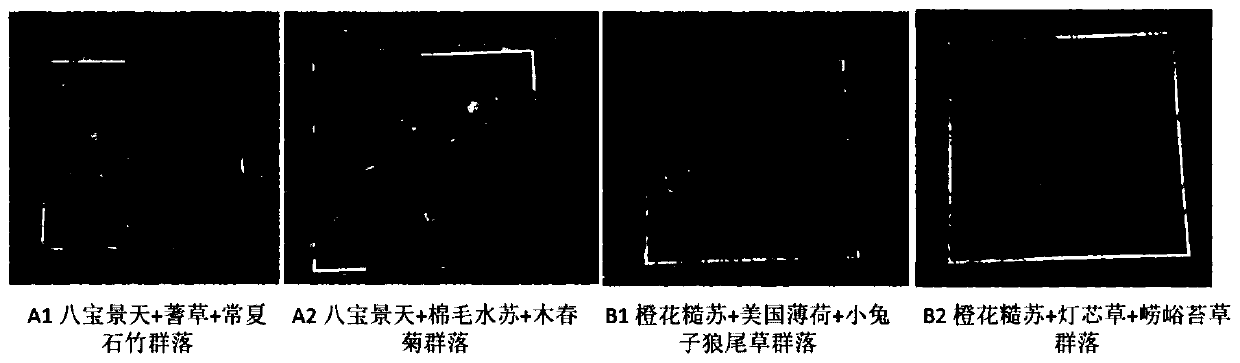

Plant community construction method

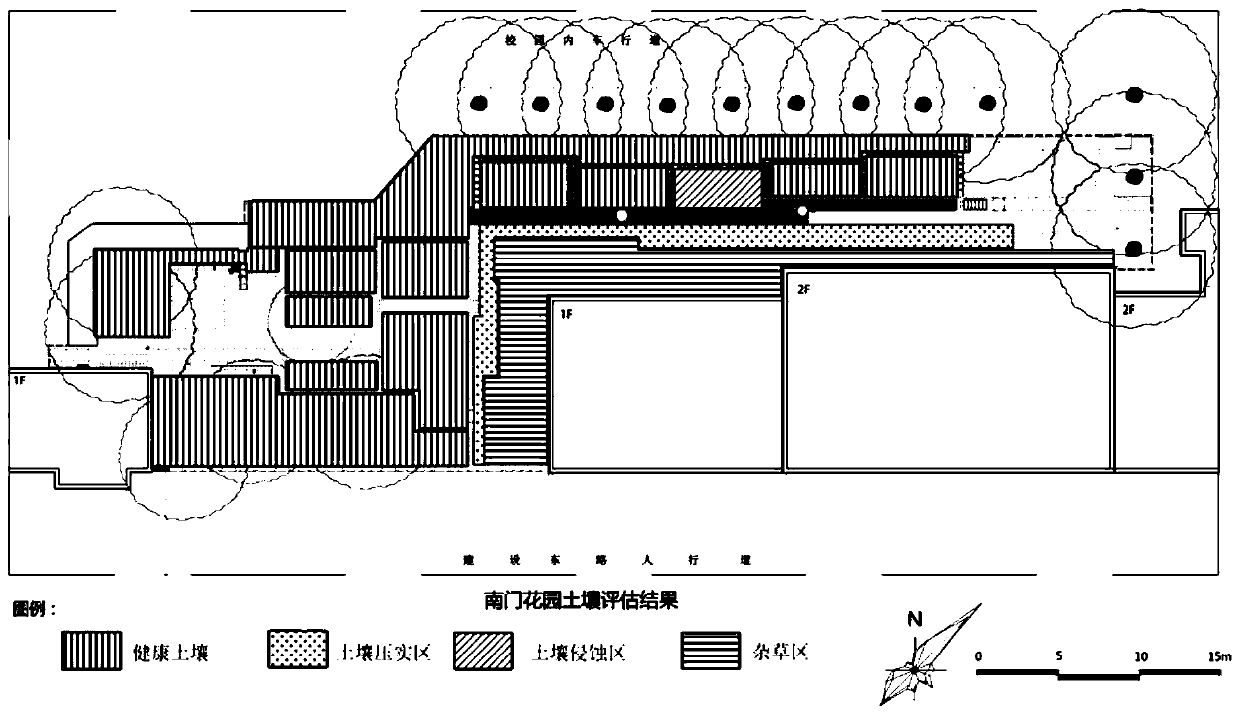

InactiveCN110326492APromote safe buildingReduce consumption intensityFlowers cultivationHops/wine cultivationDesign patternHabitat

The invention provides a plant community construction method. A plant community constructed by the method is suitable for the climate and soil environment of the northwest regions, and the method comprises the following steps: (1) soil quality evaluation; (2) soil improvement; (3) plant community construction; and (4) continuity design. The plant community construction method has the effects thatthrough the combination of ecology and design creation as well as the application of a principle of plant community science, site design is taken as a starting point, and the basic method for constructing the ground cover plant community on a site scale is proposed; the characteristics of regional climate, environment and typical engineering habitats are taken into full account, and based on the differences in vegetation structure characteristics and functional roles, a layered design pattern of structural layer + seasonal theme layer + ground cover layer is innovatively proposed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Board for compartment and preparation method thereof

InactiveCN107225814AReduce manufacturing costLight and goodSynthetic resin layered productsLaminationFiberSlag

The invention discloses a board for a compartment and a preparation method thereof. The board comprises a substrate layer and waterproof surface layers arranged on two surfaces of the substrate layer, wherein the substrate layer comprises fly ash, slag, plant fiber, wood chips, waste plastics, calcium carbonate, vitrified beads, quartz powder, high-viscosity attapulgite clay and an ethylene-vinyl acetate copolymer; the waterproof surface layers are graphene-modified polyethylene board layers; and the substrate layer is connected with the waterproof surface layers by an adhesive. The preparation method comprises the following steps: crushing all the components at first, adding the crushed components into a mixing roll for uniform mixing, and then adding the obtained mixture into a forming machine for foaming and molding so as to obtain the substrate layer; then separately coating the upper surface and the lower surface of the substrate layer with the adhesive; and then respectively adhering the waterproof surface layers onto the upper surface and the lower surface of the substrate layer so as to obtain the board for the compartment. The board provided by the invention has the advantages of low production cost and light weight, also has good water resistance, thermal insulation performance and sound insulation performance and shows good application value.

Owner:合肥永泰新型建材有限公司

Method for establishing plant community in North China

InactiveCN101836543AReduced safety builtPromote safe buildingExcavationsSeed coating/dressingVegetation successionFertilizer

The invention provides a method for establishing a plant community in North China, comprising the following steps of: selecting seeds of herbaceous plants, shrubs and arbors; processing a part of the seeds; preparing the mixed seeds; preparing the base material mixture; preparing the base material mixture of the seeds; jetting the base material mixture of the seeds; controlling height of the herbaceous plants and densities of the shrubs and arbors; spraying cycocel soup to the herbaceous plants; spraying stress resistant high nutritive foliar fertilizers to the shrubs and arbors; and finally performing routine management. The method can promote the seeds to germinate rapidly and safely, ensure that the artificial vegetations are structurally and functionally stable, effectively shorten the succession period from the artificial vegetations to the natural vegetations and establish the plant community on wound surface of rock-soil and degraded land of side slopes, waste disposal areas and mining areas and the like in North China.

Owner:SICHUAN UNIV

Method for establishing plant community in East China

InactiveCN101836547AImprove germination rateScientific control of seeding rateExcavationsForestryPlant communityNorth china

The invention provides a method for establishing a plant community in East China, comprising the following steps of: selecting appropriate seeds of herbaceous plants, shrubs and arbors; processing the germinated seeds; preparing the mixed seeds; preparing the base material mixture; preparing the base material mixture of the seeds; jetting the base material mixture of the seeds; controlling height of the herbaceous plants and densities of the shrubs and arbors; spraying cycocel soup to the herbaceous plants; spraying stress resistant high nutritive foliar fertilizers to the shrubs and arbors; and finally performing routine management. The method can promote the seeds to germinate rapidly and safely, ensure that the artificial vegetations are structurally and functionally stable, effectively shorten the succession period from the artificial vegetations to the natural vegetations and establish the plant community on wound surface of rock-soil and degraded land of side slopes, waste disposal areas and mining areas and the like in North China.

Owner:SICHUAN UNIV

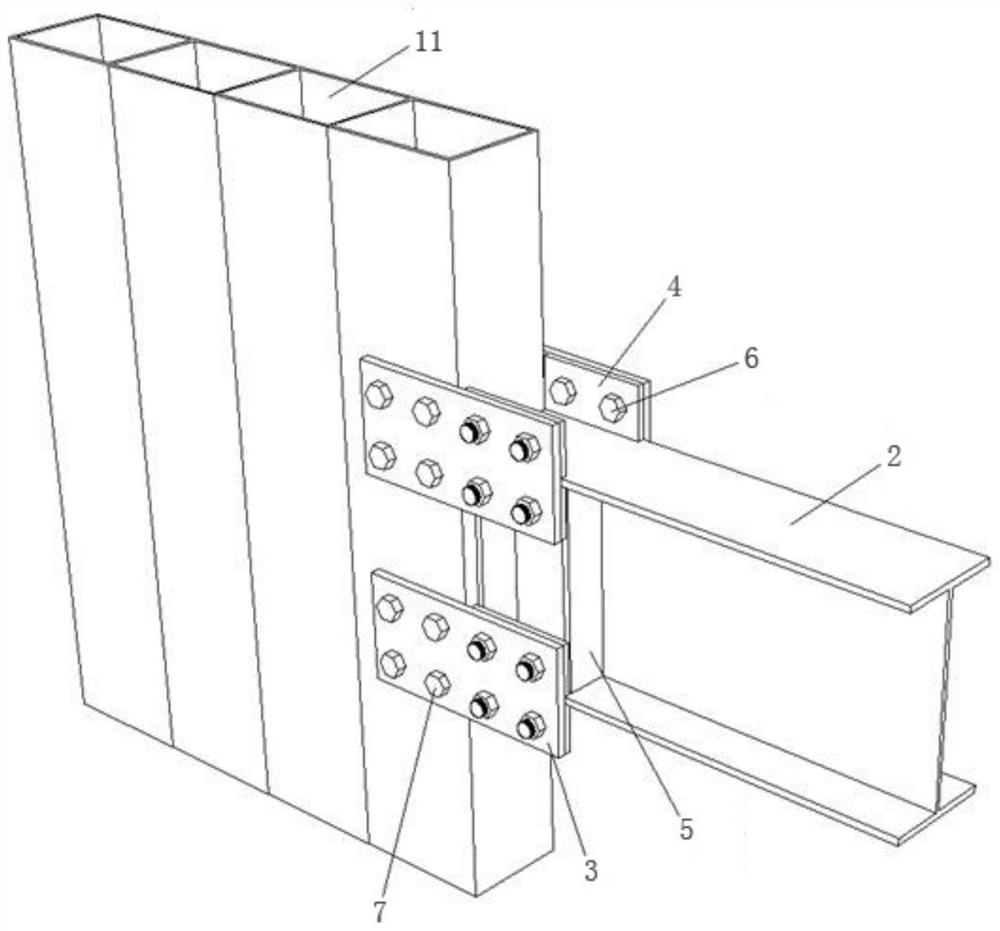

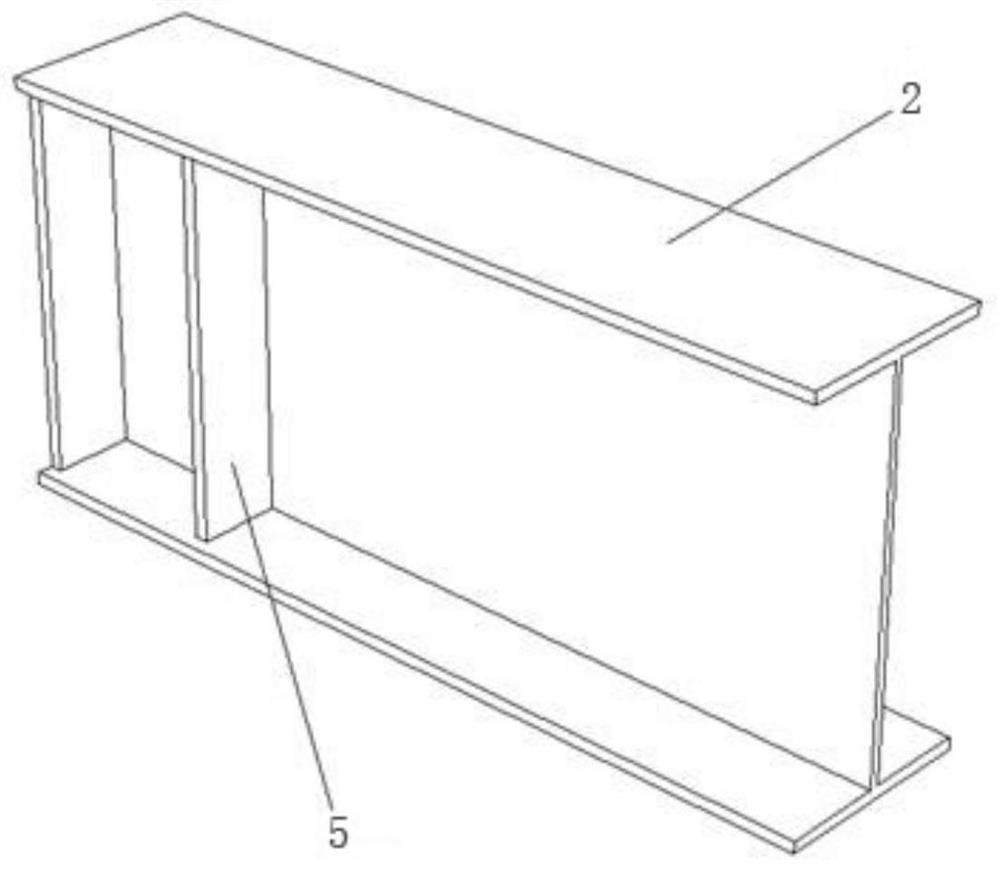

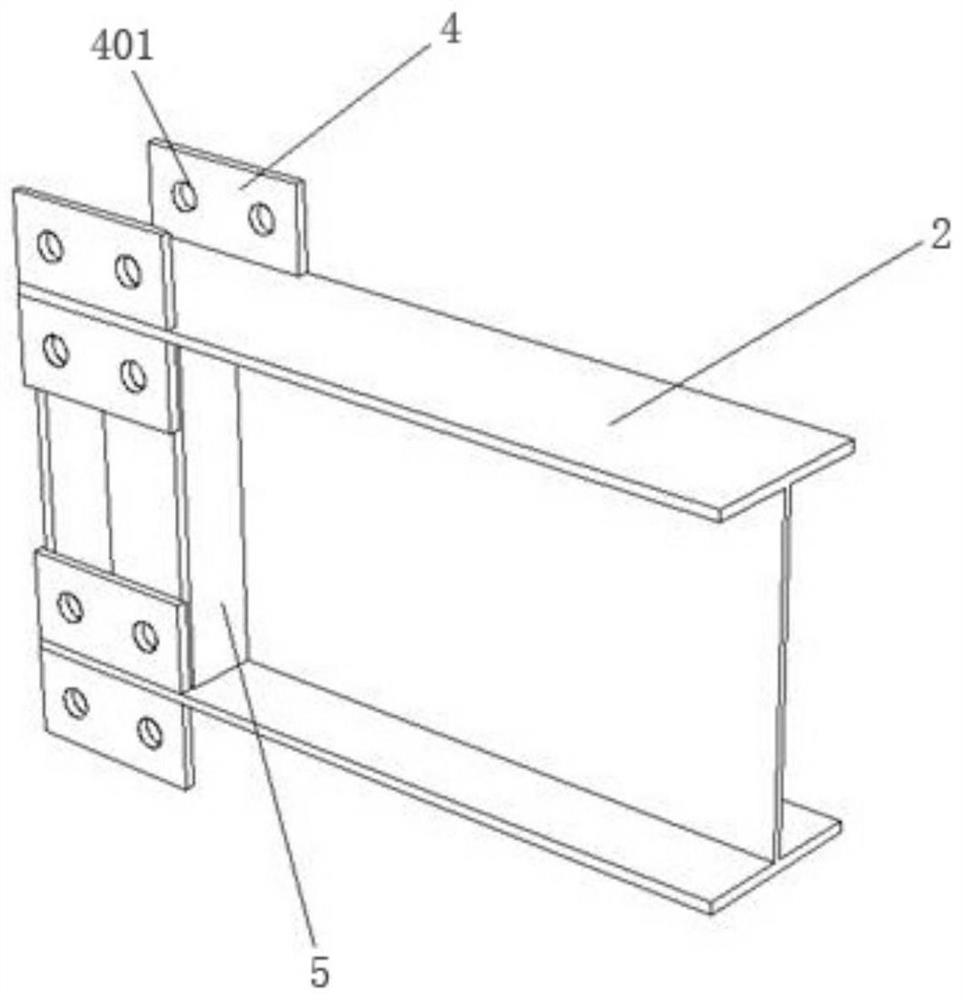

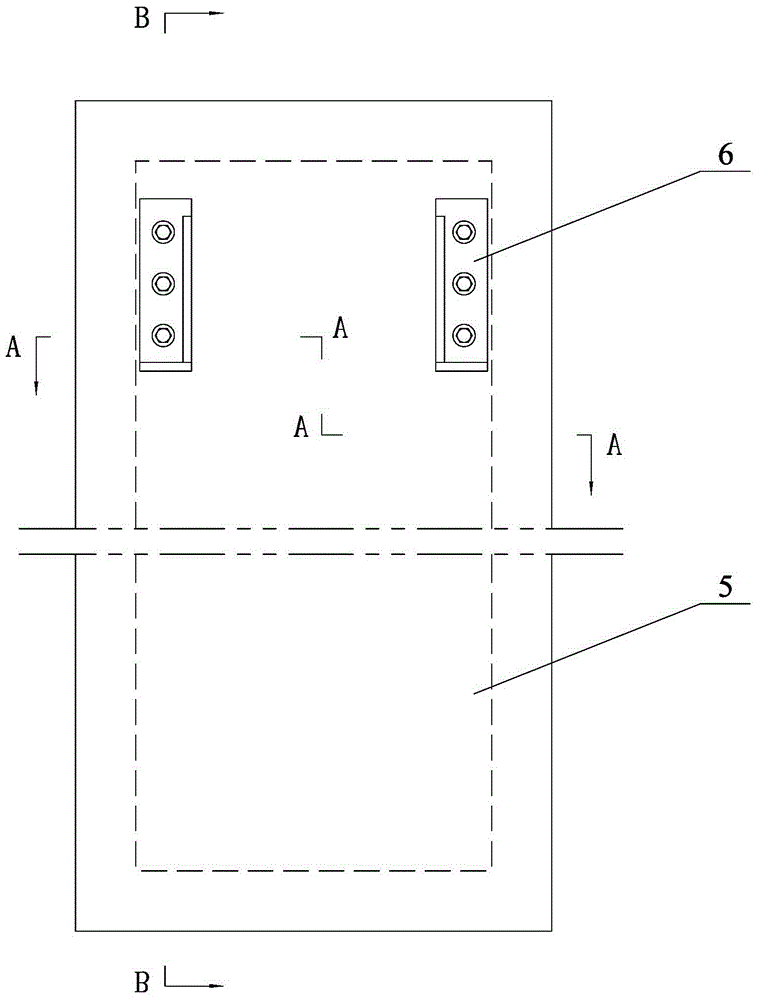

Fabricated side plate joint of steel beam and concrete-filled steel tube vertical element

PendingCN112523367APrevent excessive deformationNodal Strength and Stiffness EnhancementsStrutsGirdersSteel tubeEarthquake resistant

The invention discloses a fabricated side plate joint of a steel beam and a concrete-filled steel tube vertical element. The joint comprises the concrete-filled steel tube vertical element, the steelbeam and a connecting assembly; the connecting assembly comprises a connecting side plate and a flange welding plate; the flange welding plate is connected with the end, close to the concrete-filled steel tube vertical element, of the steel beam; the end, close to the steel beam, of the connecting side plate is attached to and connected with the side face of the corresponding flange welding plateon the steel beam; and the end, close to the concrete-filled steel tube vertical element, of the connecting side plate is attached to and connected with the side wall of the tail end of the concrete-filled steel tube vertical element. According to the fabricated side plate joint of the steel beam and the concrete-filled steel tube vertical element, on the premise that joint connection is rigid andconnection is safe and reliable, joint on-site welding work is avoided, joint on-site full-bolt connection is achieved, the problems that bolts are difficult to tighten and construction is complex ina closed section are solved, the construction efficiency is remarkably improved, the influence on the environment is small, good anti-seismic performance is achieved, and the steel structure fabricated building technology can be perfected.

Owner:CHINA SOUTHWEST ARCHITECTURAL DESIGN & RES INST CORP LTD

Plant community constructing method in northeastern area

InactiveCN101836545APromote safe buildingImprove germination rateSeed and root treatmentClimate change adaptationPlant communityVegetation succession

The invention provides a plant community constructing method in the northeastern area, which comprises the following steps of: selecting herb, shrub and arbor seeds; treating seeds difficult to sprout; preparing a seed mixture; preparing a base material mixture; preparing a seed and base material mixture; spraying the seed and base material mixture to rock-soil wound surfaces or degraded lands; controlling the height of herbs and the density of shrubs and arbors; spraying paclobutrazol liquor to the herbs; spraying a stress-resisting foliage fertilizer to the shrubs and the arbors; and conventionally managing moisture and nutrients. The method ensures fast and safe seed sprouting, guarantees stable structure and functions of artificial vegetations, and shortens the succession period of the artificial vegetations into natural vegetations. The plant community constructing method is used for the rock-soil wound surfaces or the degraded lands, such as side slopes, waste disposal areas, mining areas and the like in the northeastern area.

Owner:SICHUAN UNIV

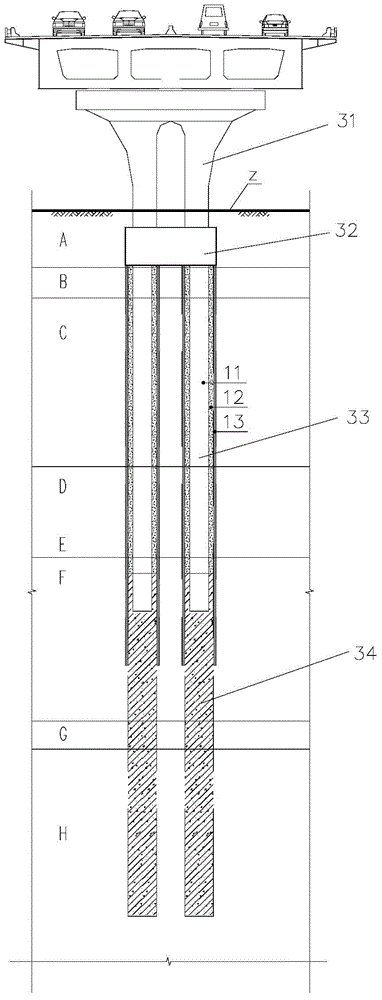

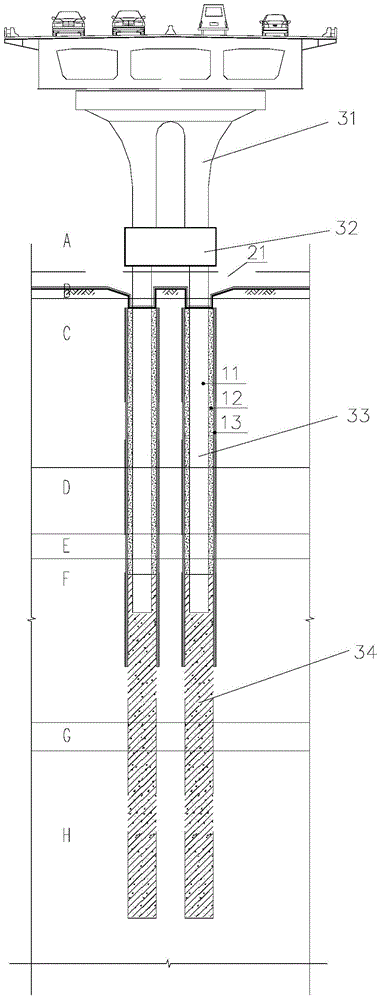

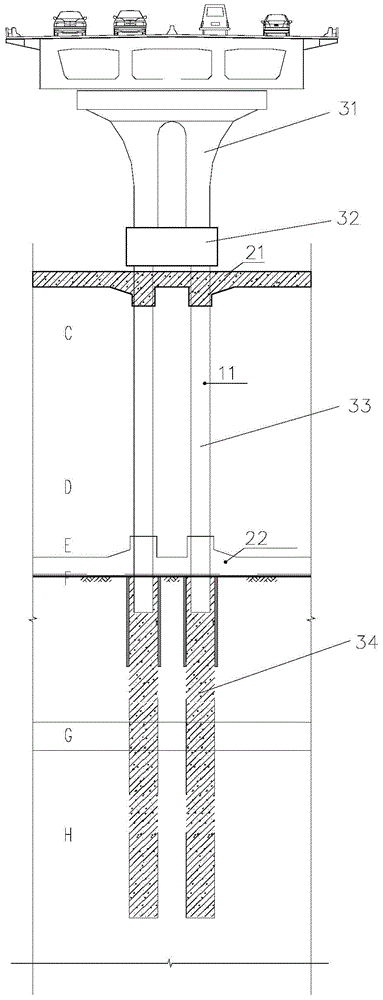

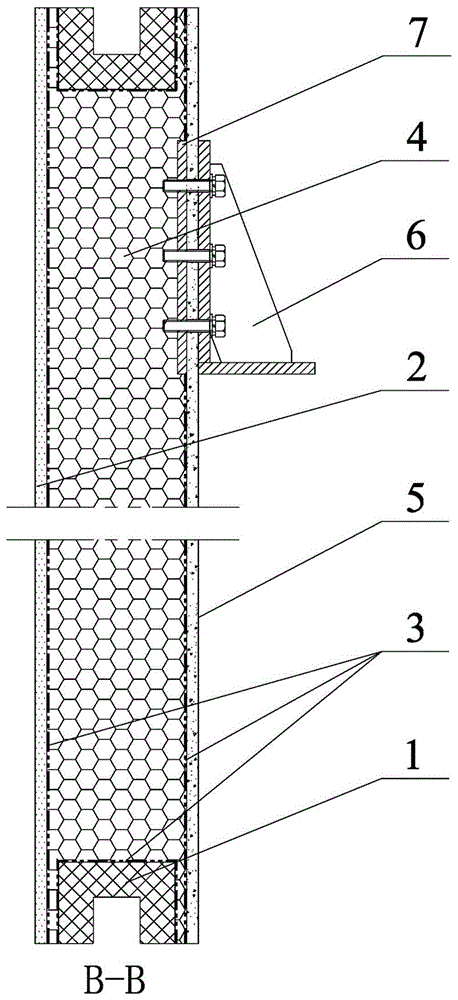

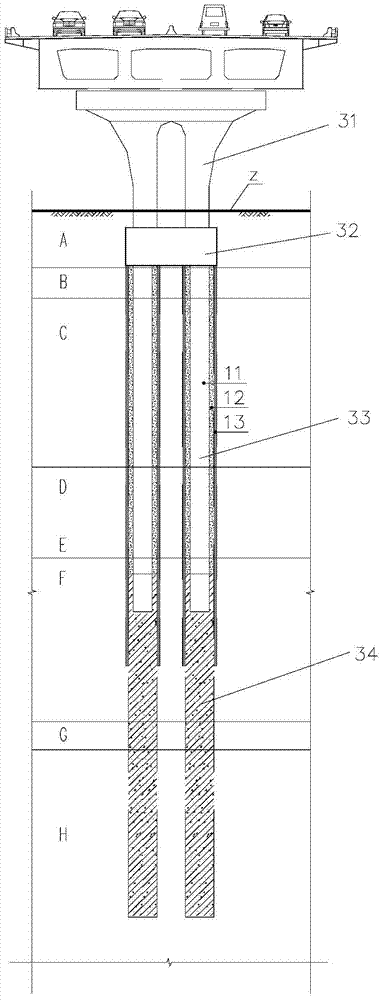

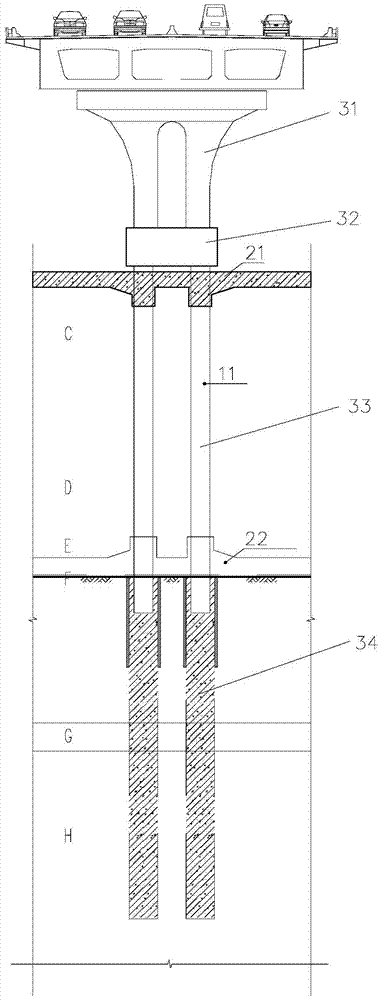

Subway station building method using bridge and station combined building mode

ActiveCN105625184AThe construction site occupies a small areaReduce the impactArtificial islandsBridge erection/assemblySubway stationGround transportation

The invention provides a subway station building method using a bridge and station combined building mode. The subway station building method using the bridge and station combined building mode comprises the following steps of first building a bridge pier which is also used as a subway station structural column; building a bridge on the bridge pier; and then beginning to build a subway station top slab and excavate a foundation pit; and finally, building a subway station bottom slab, a foundation pit fender post and the rest structures. According to the invention, small area occupied by a construction site and small influence on ground transportation in the whole construction process are ensured; and four walls of the whole subway station are stably stressed in the later stage, the stress cannot make a big difference, and the stability and safety of the subway station are enhanced.

Owner:GUANGZHOU METRO DESIGN & RES INST

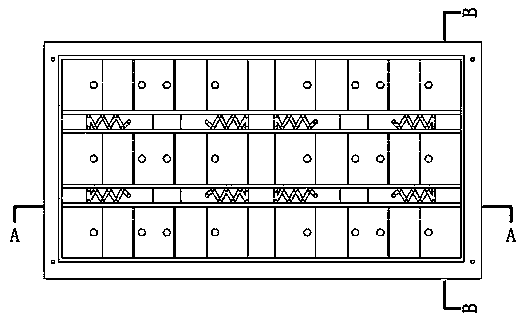

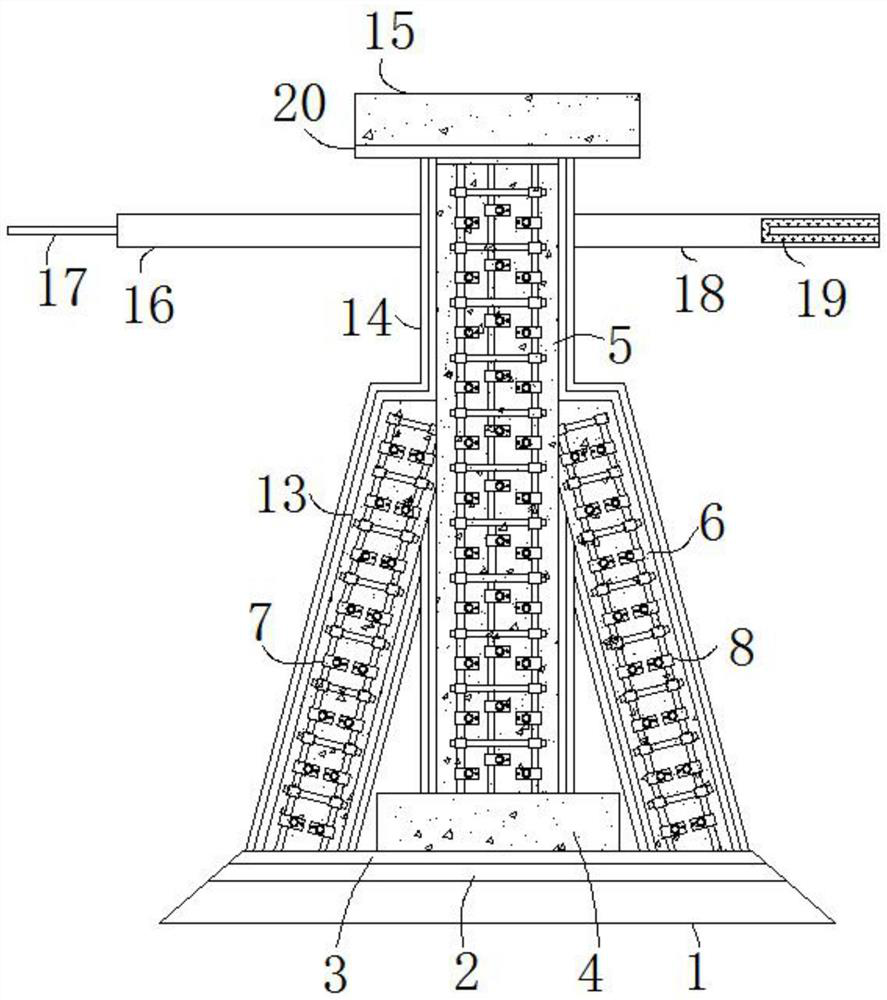

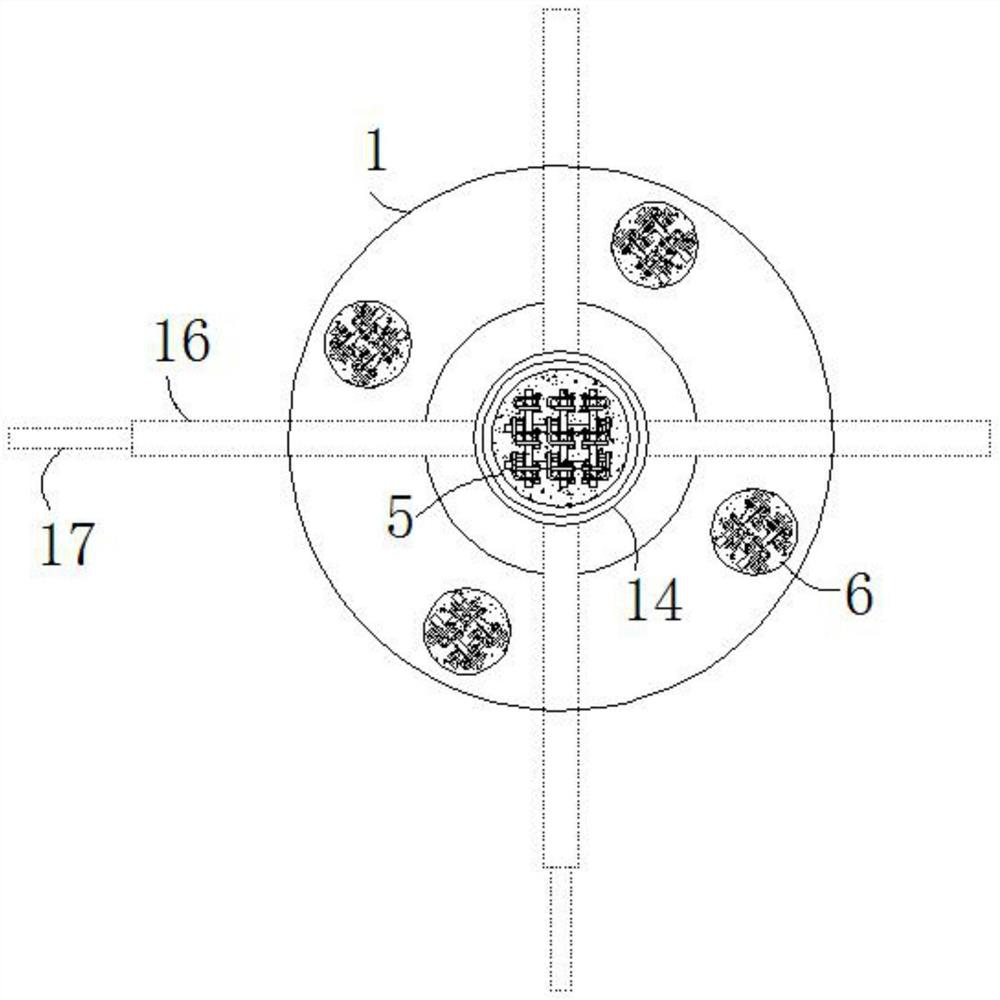

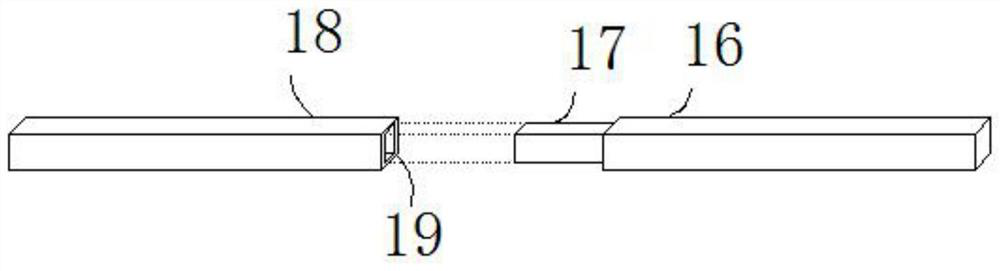

Assembly-type prefabricated concrete column without dismantling formworks and preparation process of assembly-type prefabricated concrete column

PendingCN111139973AEasy to assembleQuick assemblyStrutsCeramic shaping apparatusArchitectural engineeringEarthquake disaster

The invention discloses an assembly-type prefabricated concrete column without dismantling the formworks and a preparation process of the assembly-type prefabricated concrete column. The assembly-typeprefabricated concrete column comprises a prefabricated concrete column body, the prefabricated concrete column body is connected with a shock absorption support through a bolt and an iron base plateand comprises the four composite formwork without dismantling, a main reinforcement and a filling concrete part, stirrups are bound on the main reinforcement at equal interval, the four composite formworks without dismantling are externally buckled on a rectangular cage reinforced skeleton frame formed by the main reinforcement and the stirrups, two rows of rectangular square grooves are formed in the inner side surface of each composite formwork without dismantling, the filling concrete part is poured in a rectangular cylinder-shaped frame defined by the composite formworks without dismantling, bolt holes corresponding to column connection holes are formed in the filling concrete part, and bolts are connected within the column connection holes and the bolt holes in a penetrating mode. According to the assembly-type prefabricated concrete column without dismantling formworks, the prefabricated concrete column body and the shock absorption support are assembled as a whole to avoid theerosion of the shock absorption support by the rain and other adverse factors, and the shock absorption support can play a high shock absorption role and reduces the damage of the whole column body inan earthquake disaster.

Owner:EAST CHINA JIAOTONG UNIVERSITY

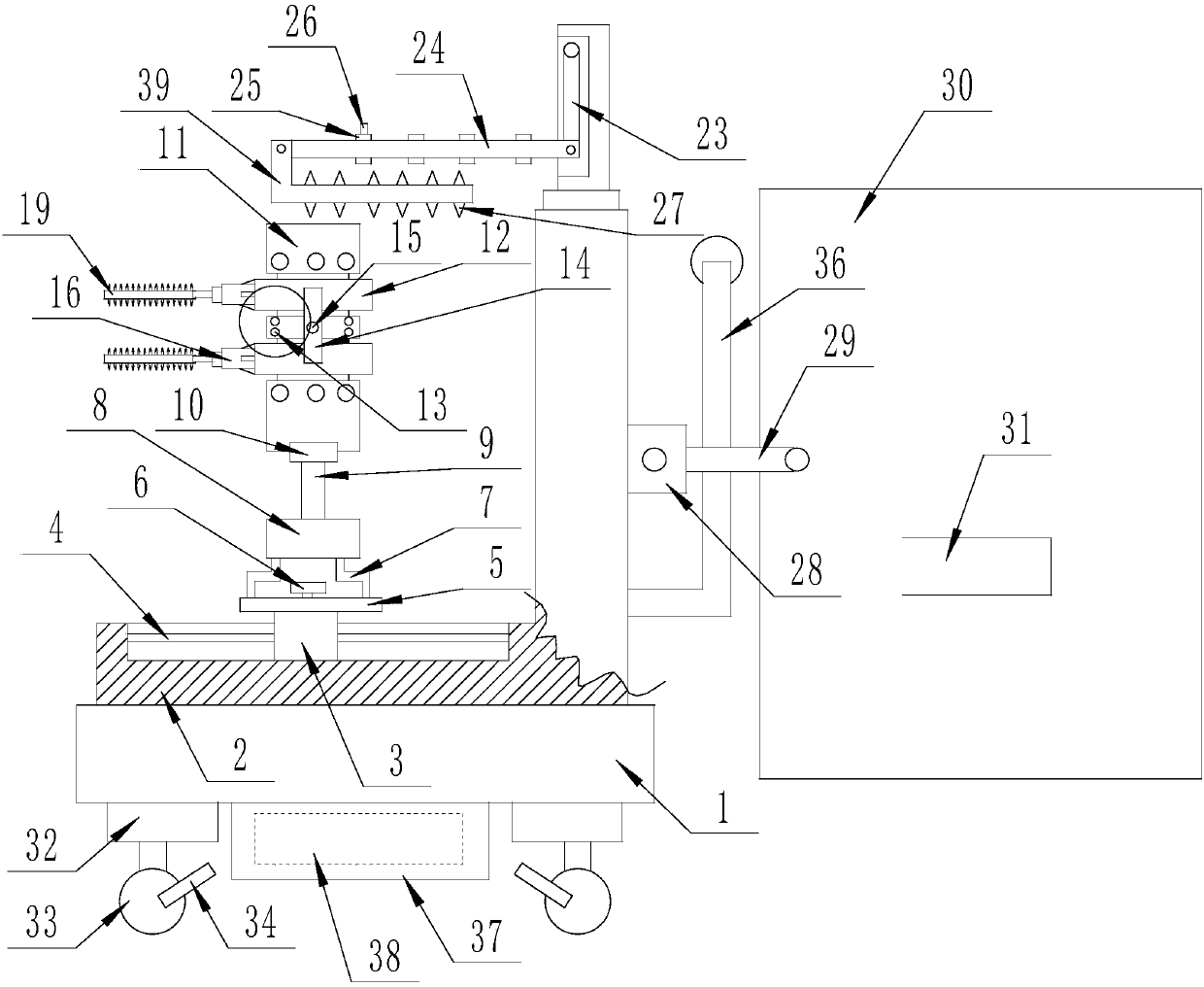

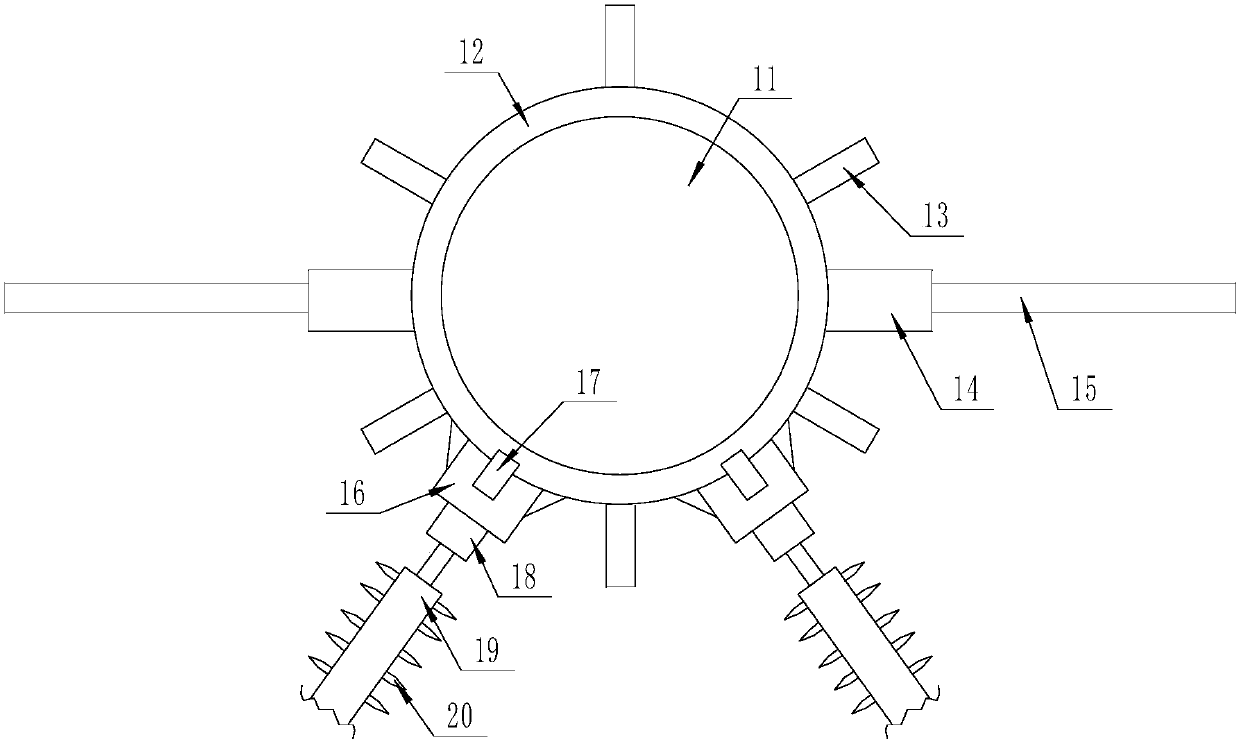

Device for removing impurities in granular building material

InactiveCN107583867APromote safe buildingEasy to cleanMixing operation control apparatusGradingImpurityBuilding construction

The invention discloses a device for removing impurities in a granular building material. The device comprises a rectangular supporting base, an L-shape fixed supporting plate is fixedly connected tothe upper surface of the rectangular supporting base, a drawing cleaning mechanism is arranged on the upper end face of the L-shape fixed supporting plate, a rotating cleaning mechanism is arranged onthe upper surface face of the L-shape fixed supporting plate, a moving mechanism is arranged on the lower surface of the rectangular supporting base, and a swinging shielding mechanism is arranged onthe outer side surface of the L-shape fixed supporting plate. The device has the advantages of being convenient to use and capable of effectively removing impurities in the granular building material, guaranteeing normal construction, relieving the labor intensity and guaranteeing the safety of a building using the building material.

Owner:宁夏博文利奥科技有限公司

Method for establishing plant community in North China

InactiveCN101836543BScientific control of seeding ratePromote growthExcavationsSeed coating/dressingPlant communityNorth china

The invention provides a method for establishing a plant community in North China, comprising the following steps of: selecting seeds of herbaceous plants, shrubs and arbors; processing a part of the seeds; preparing the mixed seeds; preparing the base material mixture; preparing the base material mixture of the seeds; jetting the base material mixture of the seeds; controlling height of the herbaceous plants and densities of the shrubs and arbors; spraying cycocel soup to the herbaceous plants; spraying stress resistant high nutritive foliar fertilizers to the shrubs and arbors; and finally performing routine management. The method can promote the seeds to germinate rapidly and safely, ensure that the artificial vegetations are structurally and functionally stable, effectively shorten the succession period from the artificial vegetations to the natural vegetations and establish the plant community on wound surface of rock-soil and degraded land of side slopes, waste disposal areas and mining areas and the like in North China.

Owner:SICHUAN UNIV

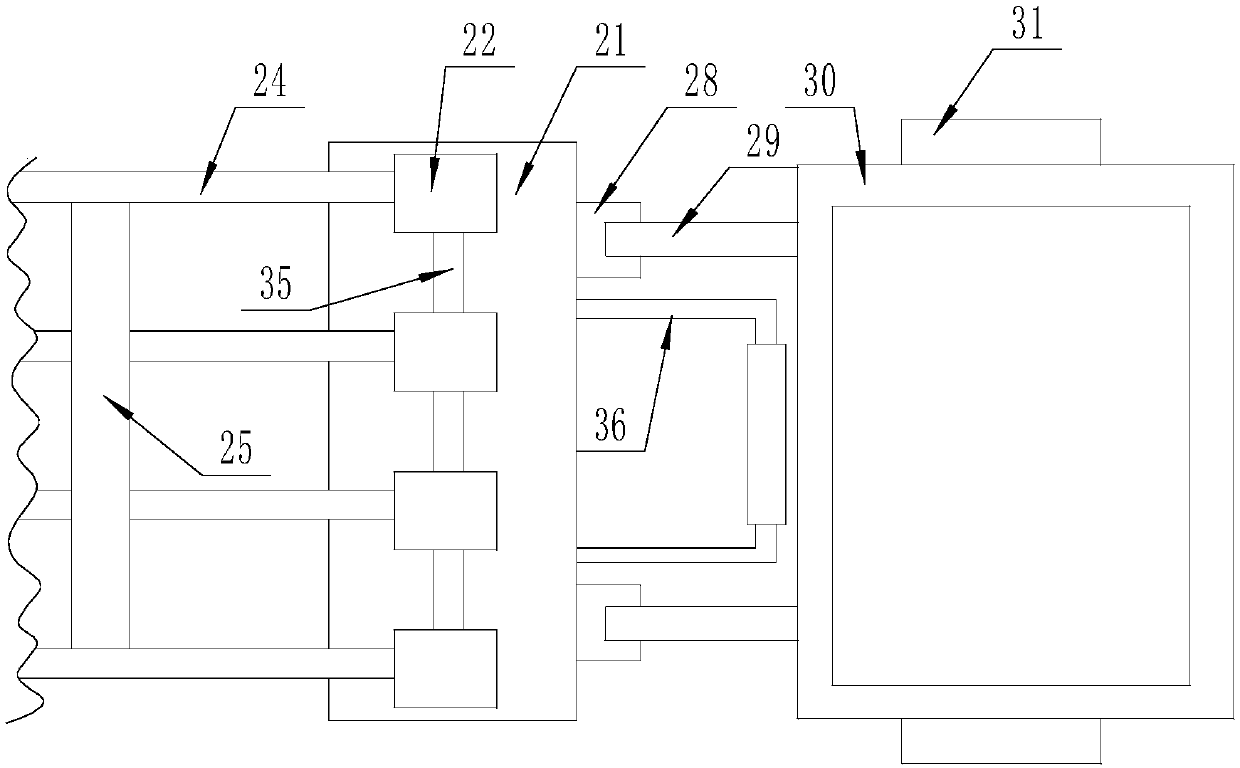

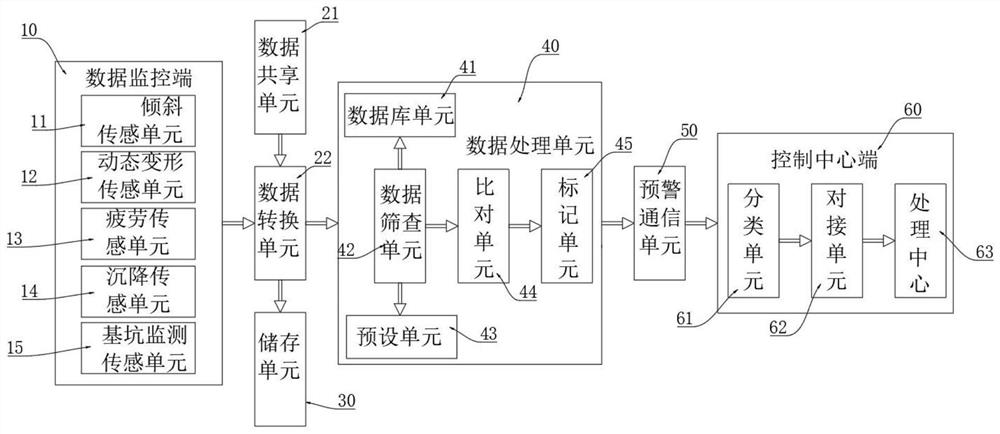

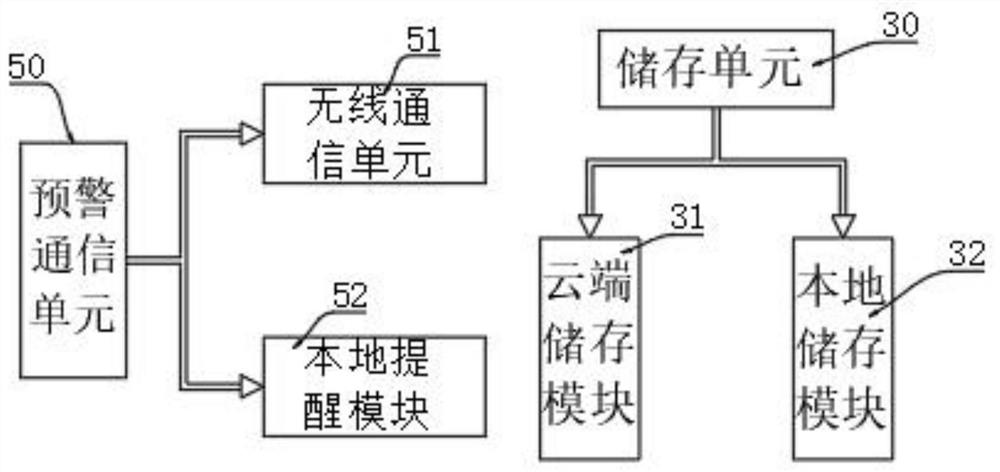

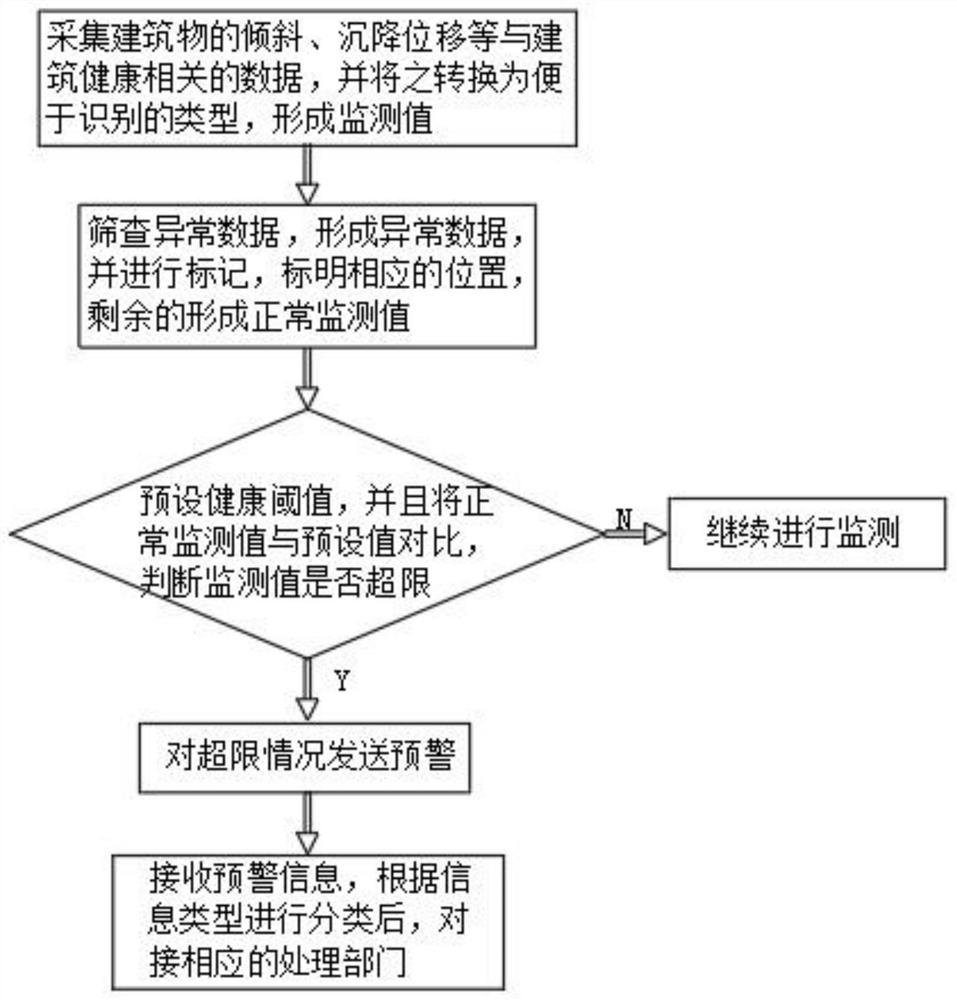

Building structure health management platform and implementation method thereof

PendingCN113902588AAvoid misjudgmentAvoid it happening againDigital data information retrievalResourcesCommunication unitData transformation

The invention discloses a building structure health management platform and an implementation method thereof, and relates to the building field, and the building structure health management platform comprises a data monitoring end, and also comprises a data processing unit which is used for calling health data obtained by a data conversion unit, screening out abnormal data, and judging whether the building structure is in a healthy state or not through the remaining normal data; an early warning communication unit which is used for sending an early warning to a user when the comparison unit outputs a result that the monitoring value is higher than a health threshold value; and a control center end which is used for calling an output result of the early warning communication unit and performing targeted processing according to the result. When health monitoring is carried out on a building structure, the platform can realize whole-process tracking, real-time early warning processing and monitoring trace storage, so that a user can conveniently take the monitoring trace at any time, and the building safety is ensured.

Owner:应急管理部四川消防研究所

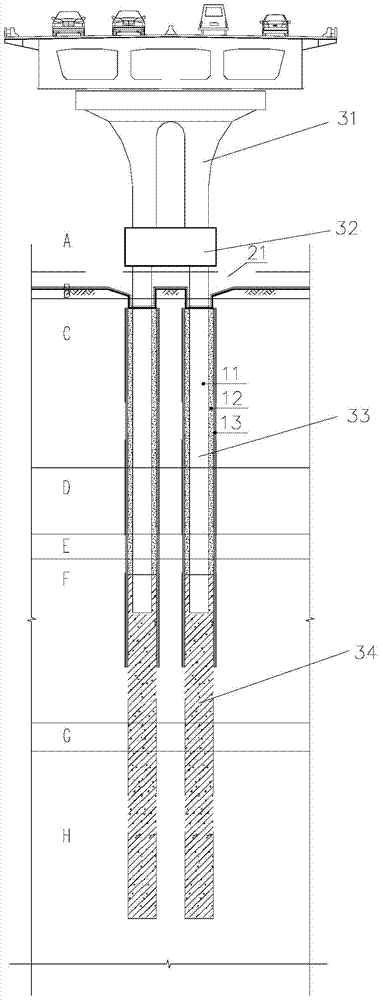

Building construction foundation pile

ActiveCN113818470AHigh strengthImprove waterproof performanceProtective foundationBulkheads/pilesEarthquake resistanceArchitectural engineering

The invention discloses a building construction foundation pile which comprises a concrete base, wherein the concrete base is poured in a drill hole, a cement stabilizing layer is laid at the top end of the concrete base, and a reinforcing layer is laid at the top end of the cement stabilizing layer; a concrete bearing seat which is poured in the middle of the upper surface of the reinforcing layer; a bearing main pile which is arranged in the middle of the upper surface of the concrete bearing seat, wherein a concrete leveling layer is arranged at the top end of the bearing main pile; secondary bearing piles which are arranged at the outer end of the main bearing pile at equal intervals; and a concrete bearing platform which is poured above the concrete leveling layer. According to the building construction foundation pile, the reinforcing bars can be conveniently and rapidly combined, the working pressure of workers is relieved, the overall strength of the foundation pile is improved, the waterproof performance is improved, a lifting space is provided for concrete combination bars used for connection and combination, and the anti-seismic performance is improved.

Owner:ZHAOQING CONSTR ENG

Method for establishing plant community in East China

InactiveCN101836547BImprove germination rateScientific control of seeding rateExcavationsForestryPlant communityNorth china

Owner:SICHUAN UNIV

Combined bearing structure unit curtain wall

InactiveCN104594535BReasonable forceTake full advantage of mechanical propertiesWallsSupporting systemEngineering

Owner:上海易旋建筑设计咨询有限公司

Construction method of subway station in bridge and station joint construction mode

ActiveCN105625184BImprove stabilityImprove securityArtificial islandsBridge erection/assemblyArchitectural engineeringSubway station

The invention provides a method for constructing a subway station in a bridge-station joint construction mode. The construction method first builds bridge piles that double as structural columns of the subway station, and then builds a bridge on the bridge piles; then starts to build the roof of the subway station and excavate the foundation pit , and finally build the base plate of the subway station, the retaining piles around the foundation pit and other structures. The invention ensures that during the whole construction process, the construction site occupies a small area and has little impact on ground traffic; the force on the four walls of the entire subway station is stable in the later stage, and the force does not produce huge changes, thereby improving the stability and safety of the subway station.

Owner:GUANGZHOU METRO DESIGN & RES INST

Construction method of plant community in Central China

InactiveCN101836544BReduce the impact of competitionImprove germination rateForestryPlant protectionPlant communityNutrition

The invention provides a construction method of plant community in Central China, comprising the following steps of selecting plant seeds; pretreating a part of the seeds; preparing a seed mixture; preparing a substrate mixture; preparing a seed and substrate mixture; jetting the seed and substrate mixture; controlling the herb height and the density of shrub and arbor; spraying paclobutrazol physic liquor to herbs; spraying stress resistant high nutrition foliar fertilizer to the arbor; and carrying out conventional management. The invention can promote the seeds to fast and safely germinate, guarantee stable structure and function of artificial vegetation, and efficiently shorten the succession period from the artificial vegetation to natural vegetation, and is used for constructing geotechnical wound surfaces including slopes, abandoned dreg sites and mining places and plant communities of degraded soils in Central China.

Owner:SICHUAN UNIV

Construction method of plant community in South China

InactiveCN101836572BScientific control of seeding rateReduced safety builtSeed and root treatmentForestryPlant communityPlanting seed

The invention provides a construction method of plant community in South China, comprising the following steps of selecting plant seeds of grasses, shrub and arbor; treating a part of the seeds; preparing a seed mixture; preparing a substrate mixture; preparing a seed and substrate mixture; jetting the seed and substrate mixture; controlling the herb height and the density of the shrub and the arbor; spraying paclobutrazol physic liquor to herbs; spraying stress resistant high nutrition foliar fertilizer to the arbor; and finally, carrying out conventional management. The invention can promote the seeds to fast and safely germinate, guarantee stable structure and function of artificial vegetation, and efficiently shorten the succession period from the artificial vegetation to natural vegetation, and is used for the construction method of geotechnical wound surfaces including slopes, abandoned dreg sites and mining places and plant communities of degraded soils in the South China.

Owner:SICHUAN UNIV

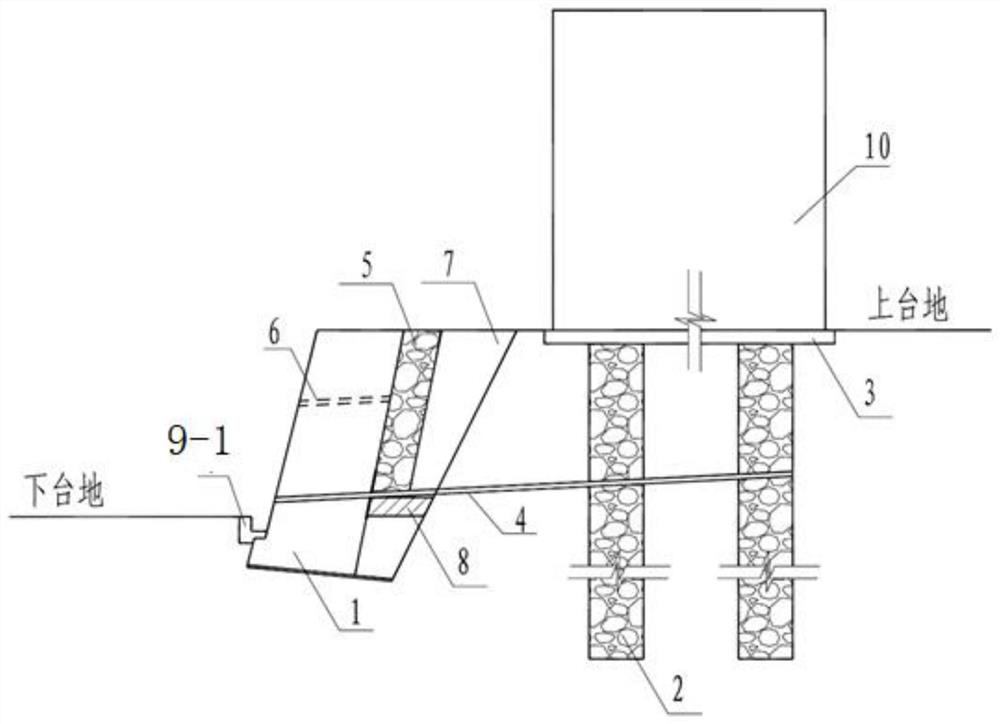

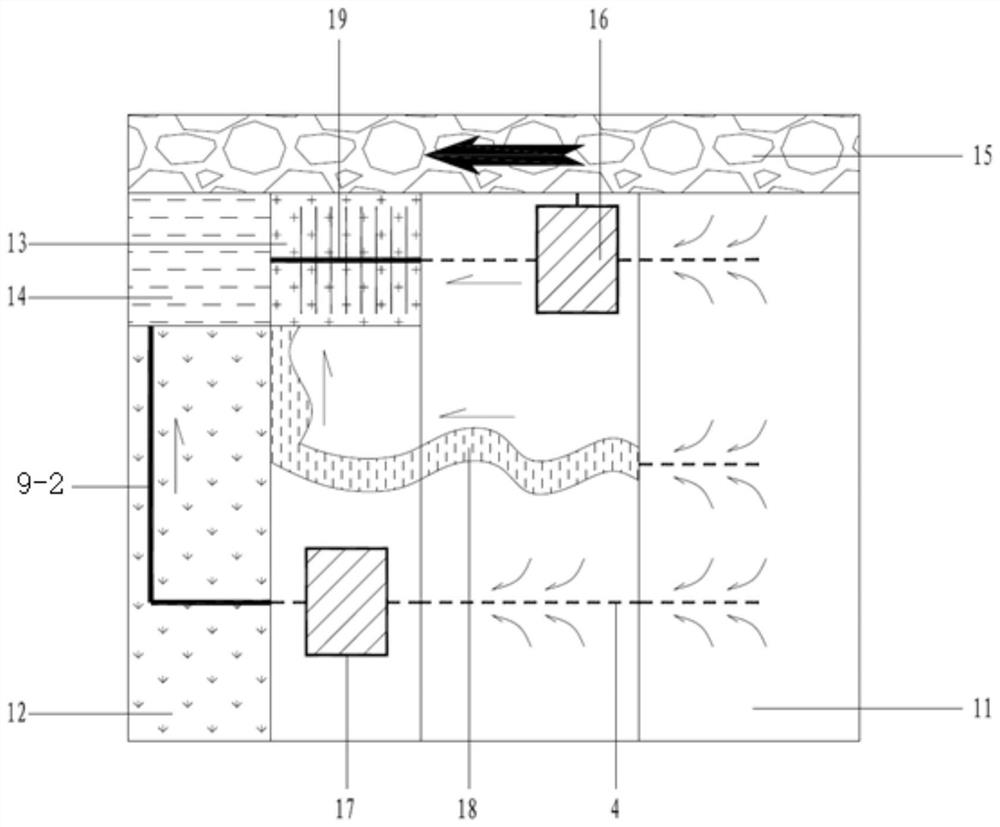

Groundwater comprehensive utilization system and method combined with seismic liquefaction foundation treatment scheme

ActiveCN112962574BEnsure building safetyEliminate earthquake liquefactionWater resource protectionSoil preservationEnvironmental resource managementCrushed stone

The invention provides a groundwater comprehensive utilization system and method combined with an earthquake liquefaction foundation treatment scheme. The system includes a living and residential area, an agricultural planting area, a landscape greening area, an ecological buffer zone, a river discharge area, and a building foundation set up in the living and residential area. Vibrating gravel piles, drainage flower pipes running through the vibrating gravel piles, and landscape water systems set up in living and residential areas; green irrigation reservoirs set up near landscape greening areas; farmland irrigation storage pools set up near agricultural planting areas The pool; the upstream of the ecological buffer zone undertakes the landscape greening area, the irrigation residual water of the agricultural planting area and the overflow of the landscape water system in the living and residential area; the river discharge area is connected with the agricultural planting area, landscape greening area, and ecological buffer zone as the lowest discharge surface in the region . The invention can discharge groundwater in time, eliminate earthquake liquefaction, and comprehensively utilize the discharged groundwater to make full use of water resources.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Construction method of plant communities in southwest area

InactiveCN101843191BPromote safe buildingReduce consumption intensitySeed and root treatmentForestryPlant communityVegetation succession

The invention provides a construction method of plant communities in the southwest area, which comprises the steps of selecting seeds; processing seeds which are difficult to germinate; preparing a mixture of seeds; preparing a mixture of substrates; preparing a mixture of seed substrates; spraying the mixture of the seed substrates towards rock soil wound surfaces or degenerated land; controlling the height of grasses and the density of bushes and arbors; spraying chlormequat chloride liquor to the grasses; spraying stress resistant high-nutrition foliar fertilizer to the arbors; and carrying out daily water and nutrient management. The seeds have rapid and safe germination, the structure and the functions of artificial vegetation are guaranteed to be steady, and the succession period from the artificial vegetation to natural vegetation is effectively shortened. The invention relates to the construction method of the plant communities on rock soil wound surfaces and in the degenerated land of side slopes, spoil areas, mining sites and the like in the southeast area.

Owner:SICHUAN UNIV

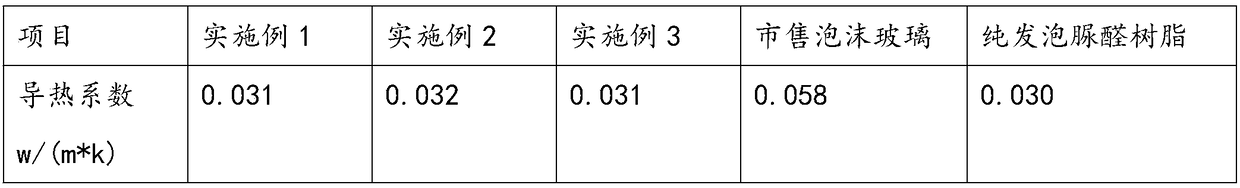

Composite flame-retardant heat-insulation material for exterior walls and method for preparing composite flame-retardant heat-insulation material

InactiveCN109438917AImprove thermal conductivityImprove insulation effectEnvironmental resistanceCasting mold

The invention discloses a composite flame-retardant heat-insulation material for exterior walls, and relates to the technical field of building materials. A method for preparing the composite flame-retardant heat-insulation material includes raw material mixing: acquiring 100 parts of urea-formaldehyde resin, 130 parts of foam glass, 0.8-1.3 parts of n-pentane and 0.35-0.50 part of emulsifiers OP-10, then preliminarily uniformly mixing the urea-formaldehyde resin, the foam glass, the n-pentane and the emulsifiers OP-10 with one another, then adding 0.5 part of curing agents into the urea-formaldehyde resin, the foam glass, the n-pentane and the emulsifiers OP-10 and uniformly stirring the curing agents, the urea-formaldehyde resin, the foam glass, the n-pentane and the emulsifiers OP-10; casting mold feeding: pouring uniformly stirred raw materials into molds; curing: placing the molds with the poured raw materials in constant-temperature tanks at the set temperatures of 50 DEG C, curing the raw materials for 30 min and then taking the prepared composite flame-retardant heat-insulation material for the exterior walls out of the molds. The composite flame-retardant heat-insulation material has the advantages that good flame-retardant and heat conduction effects can be realized by the composite flame-retardant heat-insulation material, waste resources can be sufficiently utilized, and the composite flame-retardant heat-insulation material is economical and environmentally friendly and is low in cost and easy to manufacture.

Owner:四川雷恩新材料有限公司

Fireproof building steel structure

The invention discloses a fireproof building steel structure. The fireproof building steel structure comprises two layers of floor slabs which are symmetrically arranged, the two layers of floor slabs are connected through a plurality of supporting steel columns which are arranged at equal intervals, a concrete wall body is jointly arranged on the supporting steel columns, and protection devices are arranged on the supporting steel columns, protection devices comprise notches formed in the two opposite side walls of the supporting steel columns, fixing layers are fixedly connected between the two opposite inner walls of the two notches, the fixing layers are made of carbon fiber reinforced matrix composites, the two fixing layers are arranged away from each other, and auxiliary blocks are fixedly connected between the related opposite inner walls of the two notches. According to the fireproof building steel structure, heat of the supporting steel columns and the concrete wall body can be absorbed by means of evaporation of water in a fire-fighting water pipe and melting of the auxiliary blocks and the like, the structural integrity of the supporting steel columns is guaranteed by means of the fixing layers, and then the structure of a device can be kept stable in a fire disaster.

Owner:李孟杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com