Assembly-type prefabricated concrete column without dismantling formworks and preparation process of assembly-type prefabricated concrete column

A prefabricated concrete, dismantling-free technology, used in manufacturing tools, columns, piers, etc., can solve problems such as structural performance degradation, achieve good shock absorption, improve overall bearing capacity, and enhance integrity and overall compressive strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

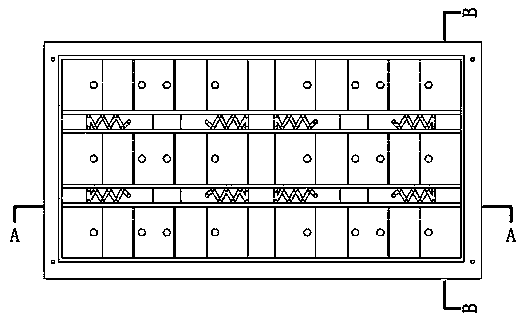

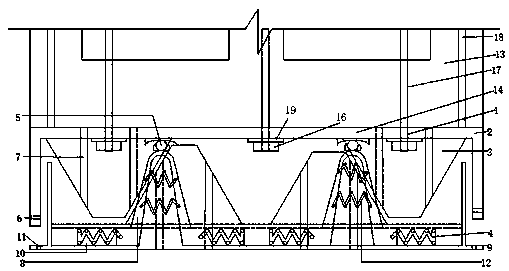

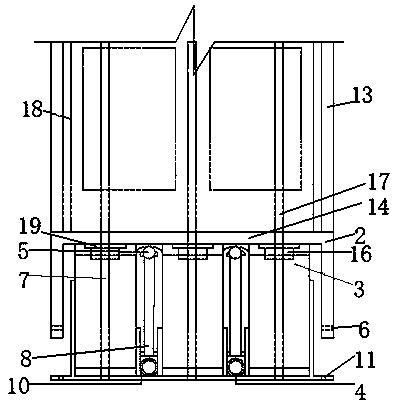

[0039] Such as Figures 1 to 8The shown assembly type prefabricated concrete column without disassembly formwork includes a shock absorbing support 14, and the shock absorbing support 14 includes an upper protective cover 2, a lower protective cover 9 and an A-shaped shrapnel 8, and the top of the upper protective cover 2 is provided with The column connection hole 1, the A-shaped shrapnel 8 are made of memory alloy and the first high-strength spring 12, the number of the first high-strength spring 12 in the middle can be adjusted according to actual needs, and the shock-absorbing support 14 also includes the second high-strength Spring 4, one end of the second high-strength spring 4 is welded together with the blocking part on the lower protective cover 9, and the other end is welded together with the bottom of the A-type shrapnel 8, and the second high-strength spring 4 is welded together with the first high-strength spring 12 The elastic coefficients are different. When the...

Embodiment 2

[0042] Such as Figures 1 to 4 , A prefabricated concrete column with an assembled formwork without disassembly shown in 9 to 12, including a shock absorber 14, and the shock absorber 14 includes an upper protective cover 2, a lower protective cover 9 and an A-shaped shrapnel 8, and the upper protective cover 2 There is a column connection hole 1 at the top of the top, the A-shaped shrapnel 8 is made of memory alloy and the first high-strength spring 12, the number of the first high-strength spring 12 in the middle can be adjusted according to actual needs, and the shock-absorbing support 14 also includes The second high-strength spring 4, one end of the second high-strength spring 4 is welded together with the blocking part on the lower protective cover 9, and the other end is welded together with the bottom of the A-type shrapnel 8, and the second high-strength spring 4 is welded together with the first The coefficient of elasticity of the high-strength spring 12 is differen...

Embodiment 3

[0045] A preparation process for prefabricated concrete columns without disassembly formwork, comprising the following steps:

[0046]Preparation of disassembly-free composite template 15: 1) Material measurement: weigh cement, sand, compacting agent and water reducer by weight, and the compacting agent is to minimize the impact of Ca(OH)2 produced in the hydration process on the glass fiber Corrosion, use self-made powdery ZQ compacting agent to improve the durability of the formwork, use medium sand with a fineness modulus of 2.5 and a bulk density of 1450Kg / m3 for the sand, and use polycarboxylate high-efficiency water reducer as the water reducer. The allowable deviation of sand is less than plus or minus 3%, and the allowable deviation of cement, compactor and water is less than plus or minus 2%; 2) Stirring and feeding: use a self-falling mixer, first add 1 / 2 of the water, and then add sand and cement , after stirring for 1 minute, add the remaining 1 / 2 of the water, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com