Fabricated side plate joint of steel beam and concrete-filled steel tube vertical element

A technology of concrete-filled steel tubes and vertical components, which is applied to building components, elongated structural components used for load-bearing, joists, etc., can solve the problems affecting the ultimate bearing capacity of connections, the need to improve the seismic performance, and the insufficient construction rate of nodes. , to solve the difficulty of tightening, the impact on the environment is small, and the construction efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

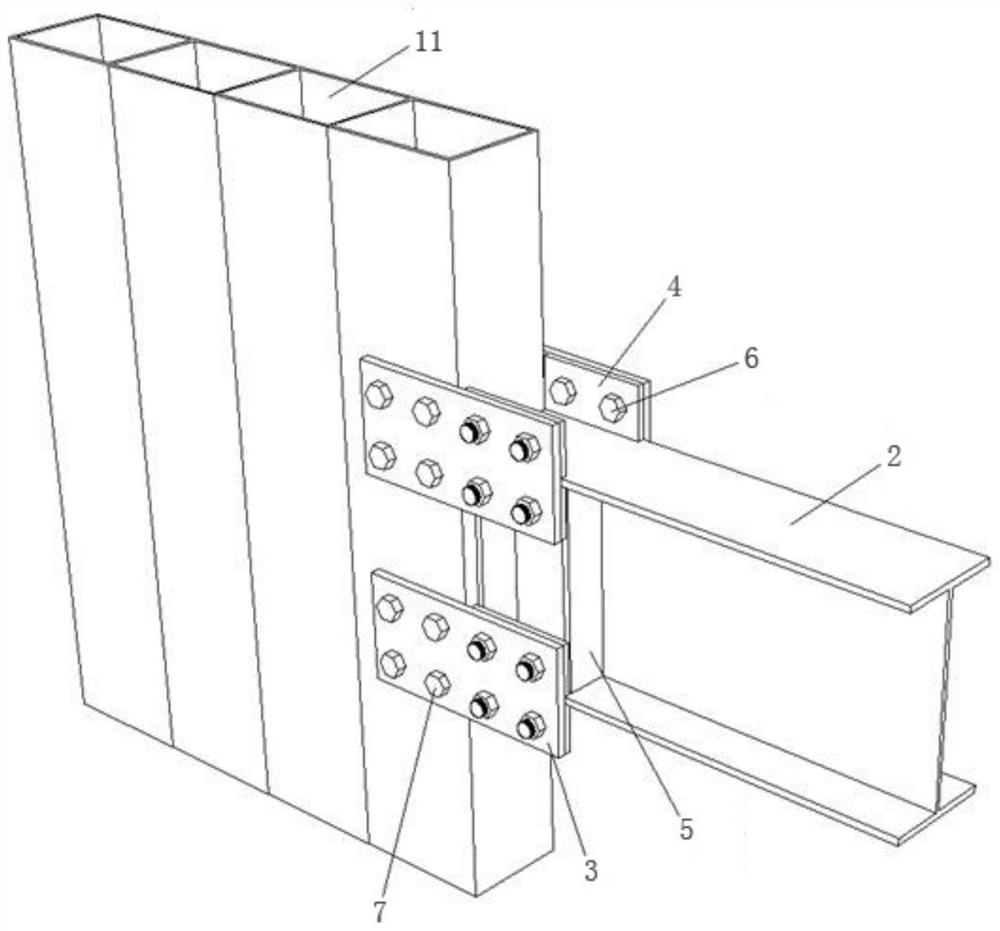

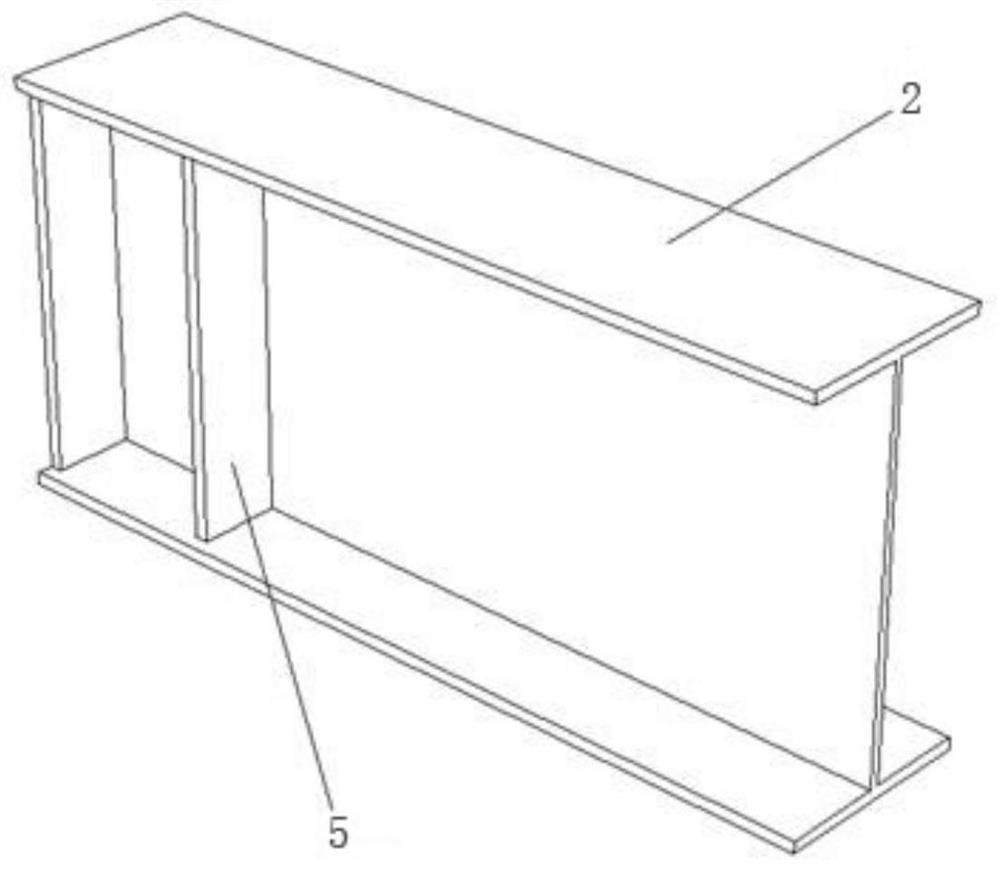

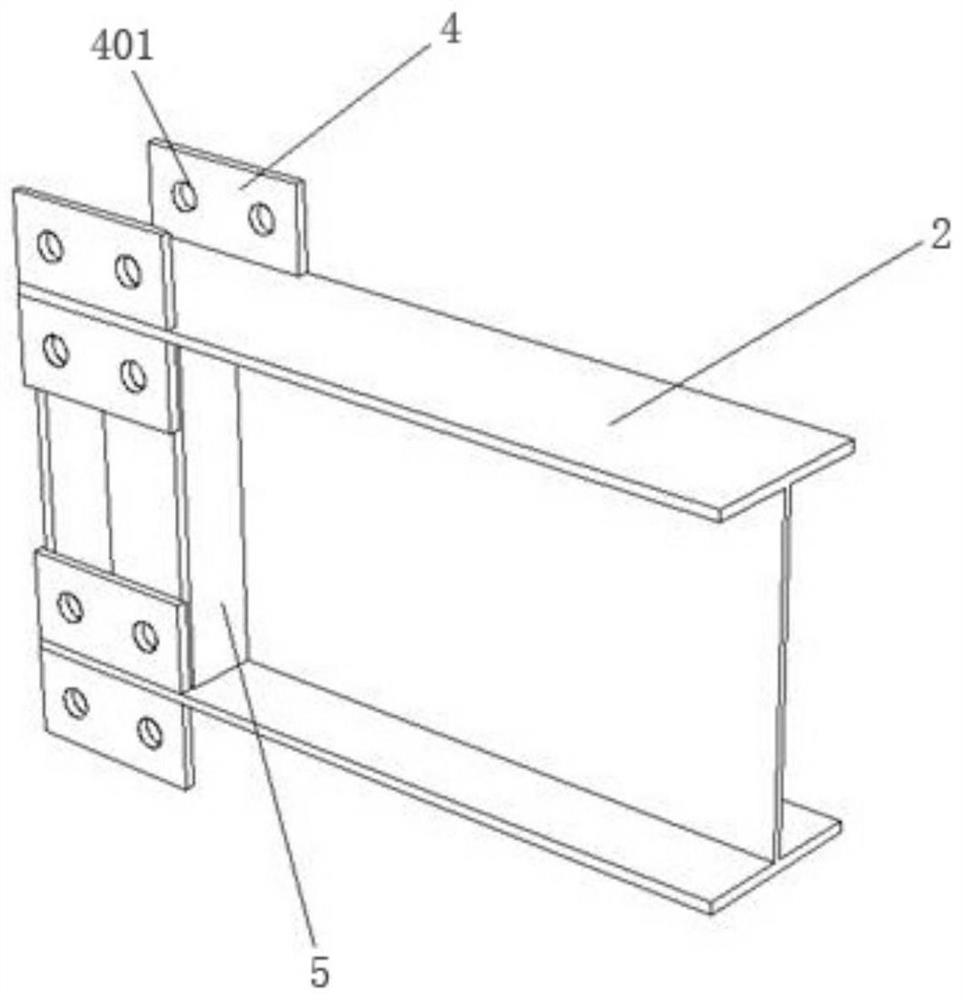

[0029] like Figures 1 to 4 As shown, a steel beam and concrete-filled steel pipe vertical member assembled side plate node includes a steel-filled steel pipe vertical member, a steel beam 2, and a connecting assembly. The two ends of the connection assembly are respectively connected with the composite structural member 11 of the steel pipe bundle and the steel beam 2 .

[0030] Specifically, the steel pipe bundle composite structural member 11 includes a vertically arranged left flange and a right flange, and a plurality of partitions are arranged at intervals between the left flange and the right flange. The steel pipe bundle composite structural member 11 consists of a left flange Edge, right flange and partitions are separated into a plurality of relatively independent units, and the units have cavities, and concrete is poured in the cavities, and the concrete can be ordinary concrete, high-strength concrete, lightweight aggregate concrete or self-compacting concrete.

...

Embodiment 2

[0041] Embodiment 2 is basically the same as Embodiment 1, and its difference is: as Figure 5 As shown, the vertical member of the concrete-filled steel tube concrete is a concrete-filled steel tube column 12, which includes a vertically arranged steel tube with a cavity, and concrete is poured into the cavity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com