Communication interface and communication method

A communication interface and communication method technology, which is applied in the field of intelligent terminal communication, can solve the problems of limited functions of intelligent terminals and inconvenient expansion interfaces, and achieve the effect of convenient function expansion and meeting individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

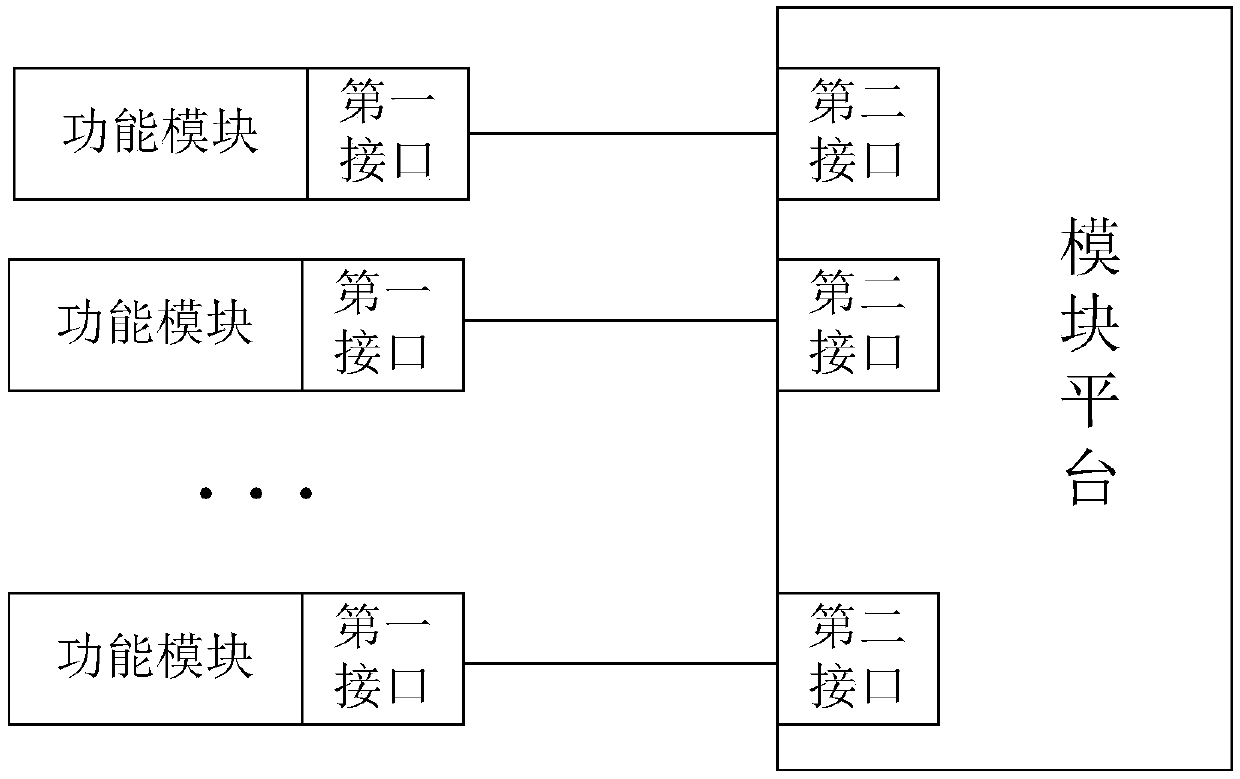

[0057] figure 1 It is a schematic diagram of the structure of the communication interface connecting the functional module and the module platform of the present invention.

[0058] Specifically, the communication interface of the present invention is used to connect and implement the communication between the module platform and the functional module. Preferably, smart terminals include but are not limited to smart phones, smart bracelets, smart glasses, etc.; smart terminals use Android operating systems, IOS operating systems, Windows operating systems, Linux operating systems, etc. Functional modules include but are not limited to: battery module, air module, water module, bracelet module, Bluetooth headset module, positioning mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com