Track assembly for tracked vehicle

一种履带、车辆的技术,应用在履带车辆、车辆无轨测试、机动车等方向,能够解决无法确认车辆状态等问题,达到提高效率和可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

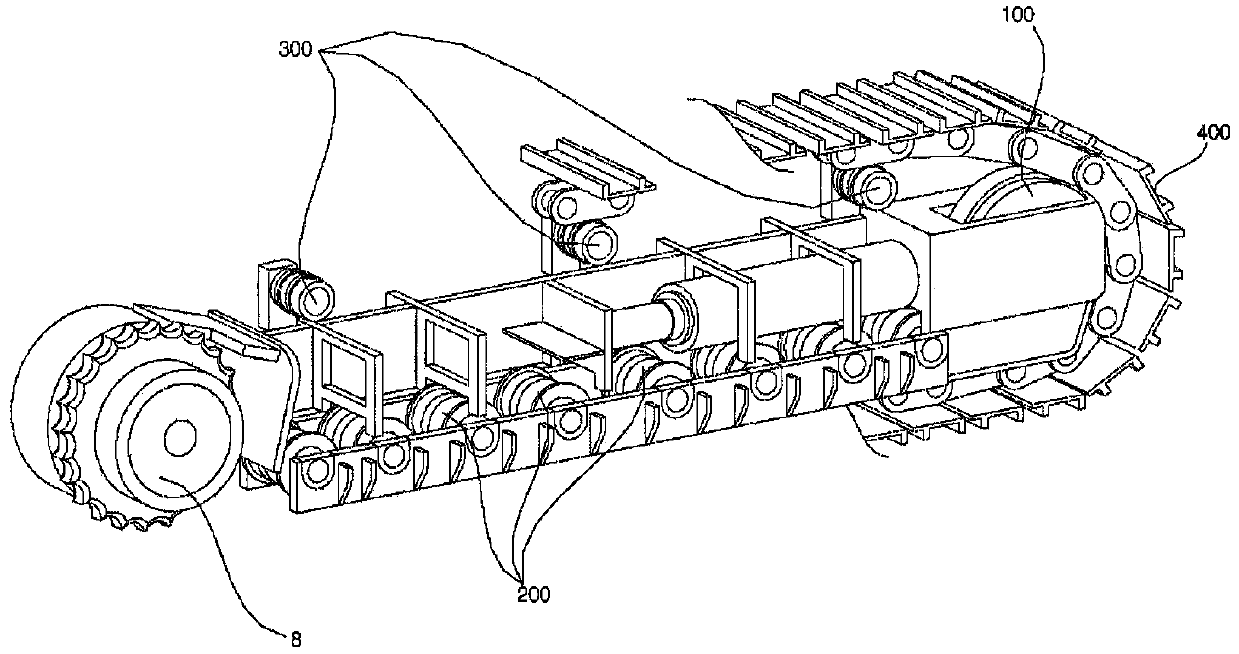

[0032] Hereinafter, a crawler belt assembly of a crawler vehicle according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

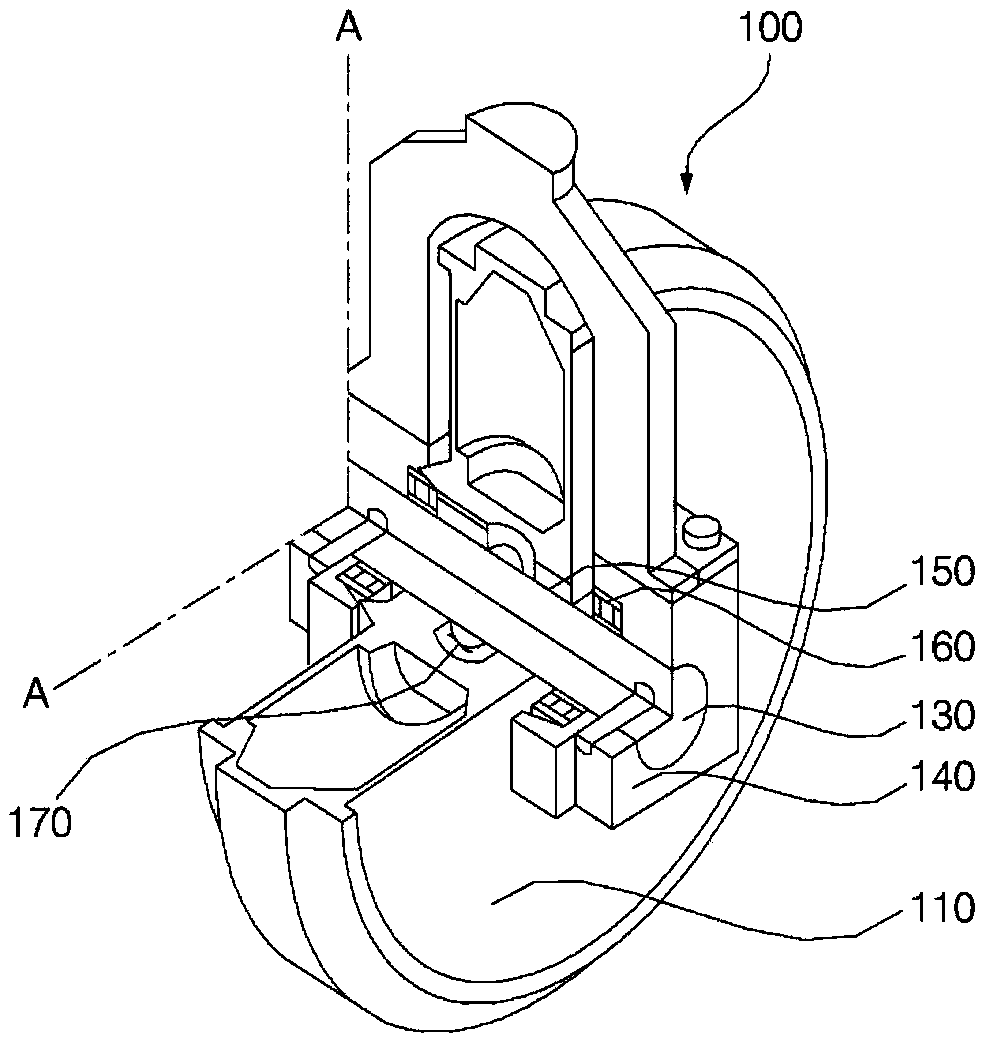

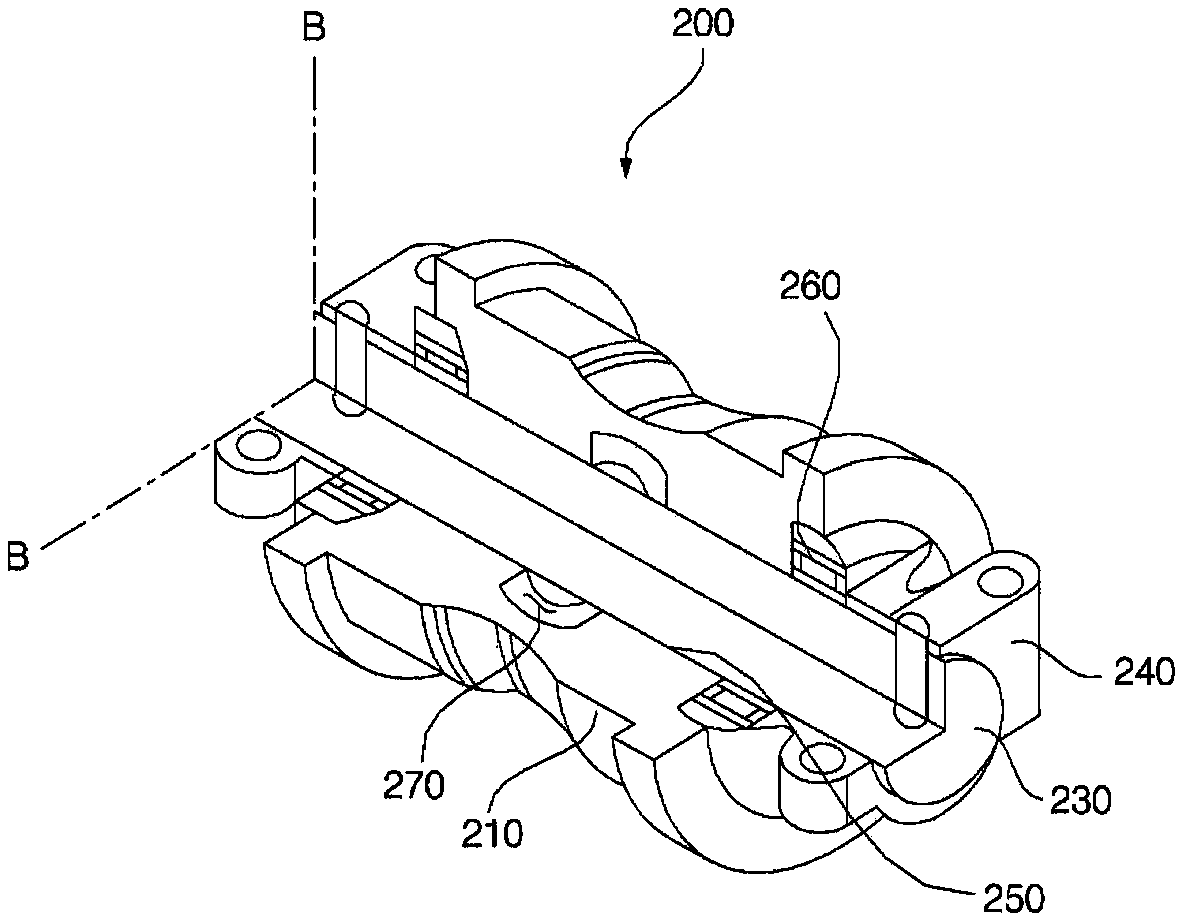

[0033] figure 1 It is a side view of an idler wheel, a support roller and an idler roller of a rotating roller having a crawler belt assembly structure of a crawler vehicle according to a preferred embodiment of the present invention, Figure 2a to Figure 2c yes figure 1 Partial cut-away perspective view of idler, track roller and roller in the structure of image 3 yes Figure 2b A cross-sectional view of the track roller in the structure, Figure 4 yes Figure 2b An exploded perspective view of the rollers in the structure.

[0034] Such as Figure 2a to Figure 2c As shown, the crawler belt assembly of a crawler vehicle in a preferred embodiment of the present invention includes: support shafts 130, 230, 330, which are configured to be orthogonal to the walking direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com