Mobile phone shell magnetic clamping fixture

A mobile phone case, magnetic technology, applied in the direction of clamping, positioning device, manufacturing tool, etc., can solve the problems of prolonged production cycle and rising production cost, and achieve the effect of simple loading and unloading and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

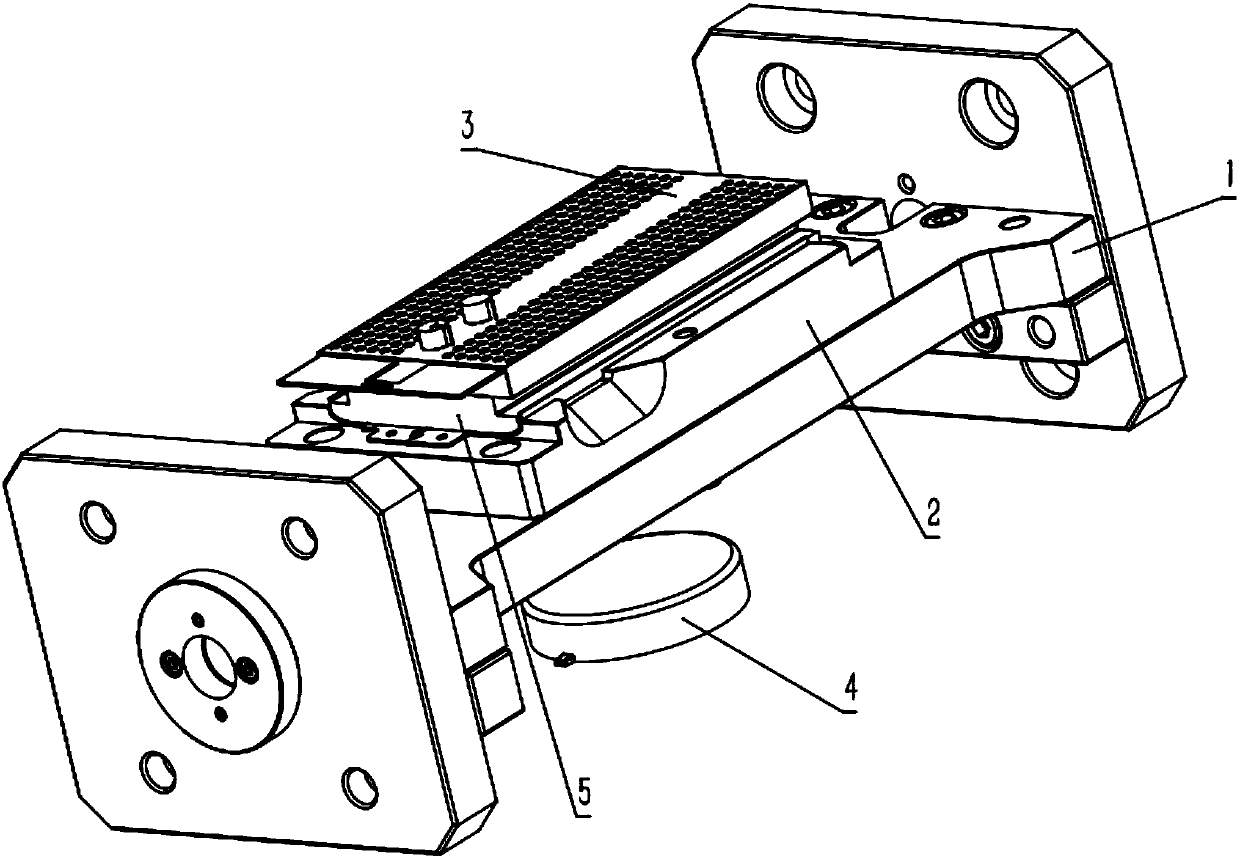

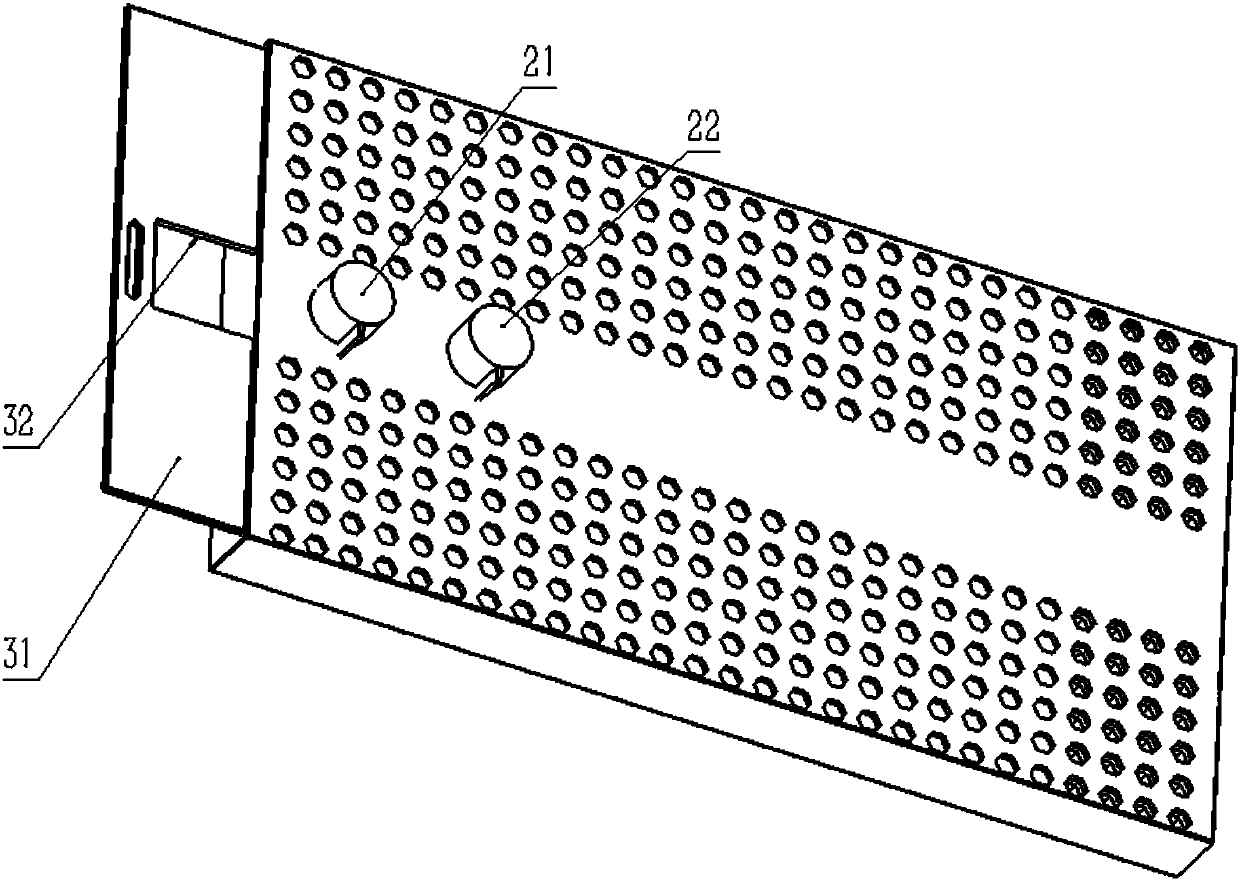

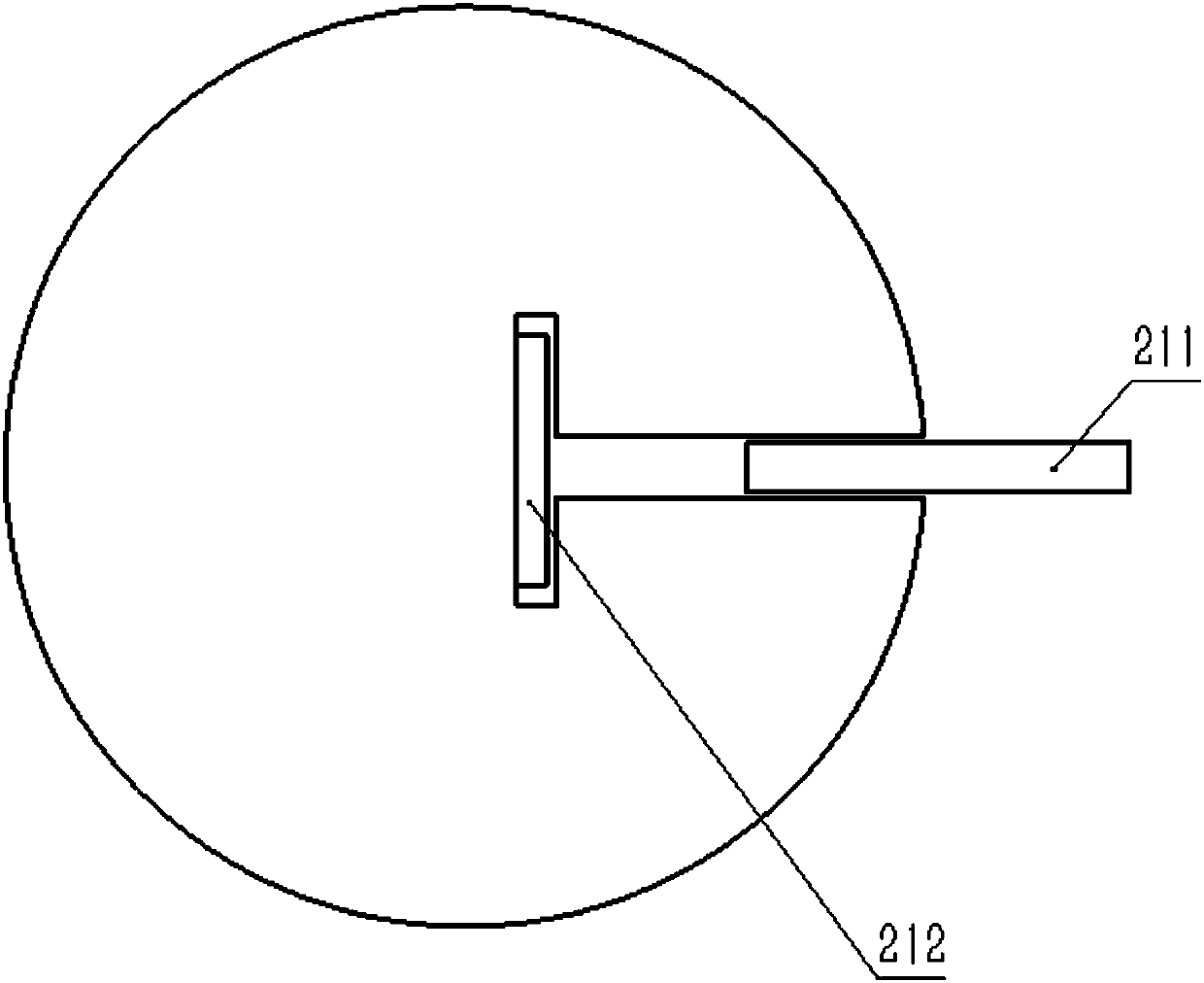

[0033] Such as Figure 1-3 As shown, a mobile phone shell magnetic clamping fixture includes: a base 1; a positioning plate 2, which is fixedly connected to the base 1, and at least a first positioning rod 21 and a first positioning rod 21 are fixedly connected to the positioning plate 2. The second positioning rod 22, the upper surface of the positioning plate 2 conforms to the shape of the mobile phone case to be processed, and the horizontal connection line direction of the first positioning rod 21 and the second positioning rod 22 is parallel to the length direction of the positioning plate 2; Pressing plate 3, the main body of which adopts a honeycomb structure, the honeycomb holes on the upper surface of the pressing plate 3 are open, the honeycomb holes on the lower surface of the pressing plate 3 are closed, the upper part of the side wall of the pressing plate 3 is provided with a first groove, and the first groove The honeycomb hole in the pressing plate is traversed...

Embodiment 2

[0040] The mobile phone shell magnetic clamping fixture also includes a rigid guard plate 5 installed between the pressing plate 3 and the positioning plate 2 . The distance between the lower surface of the first permanent magnet block 211 and the upper surface of the positioning plate 2 is equal to the sum of the thickness of the mobile phone case, the thickness of the rigid guard plate 5 and the thickness of the pressure plate 3 . The rigid guard 5 is used to increase the rigidity of the mobile phone case, so that the tool can use greater power and speed when processing the mobile phone case, thereby improving production efficiency. Due to the increase of the rigid guard plate 5 in this embodiment, the height of the corresponding lower surface of the first permanent magnet block 211 from the upper surface of the positioning plate should also be adjusted correspondingly to the thickness of the mobile phone case and the rigid guard plate 5. The sum of the thickness and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com