Device for automatically picking piles of optical disks and placing one or more optical disks

A CD-ROM and automatic technology, applied in the direction of transportation and packaging, packaging, manipulators, etc., can solve the problems of high cost, high labor cost, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

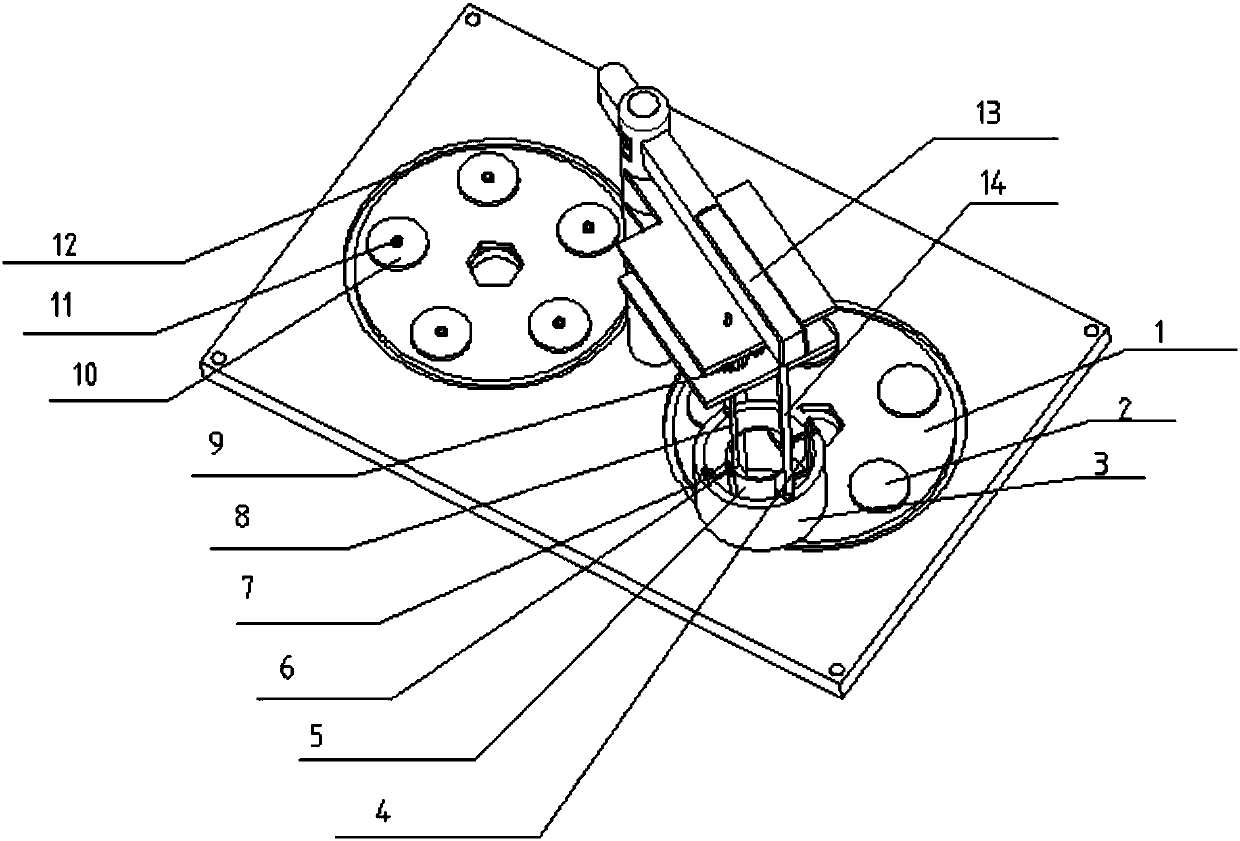

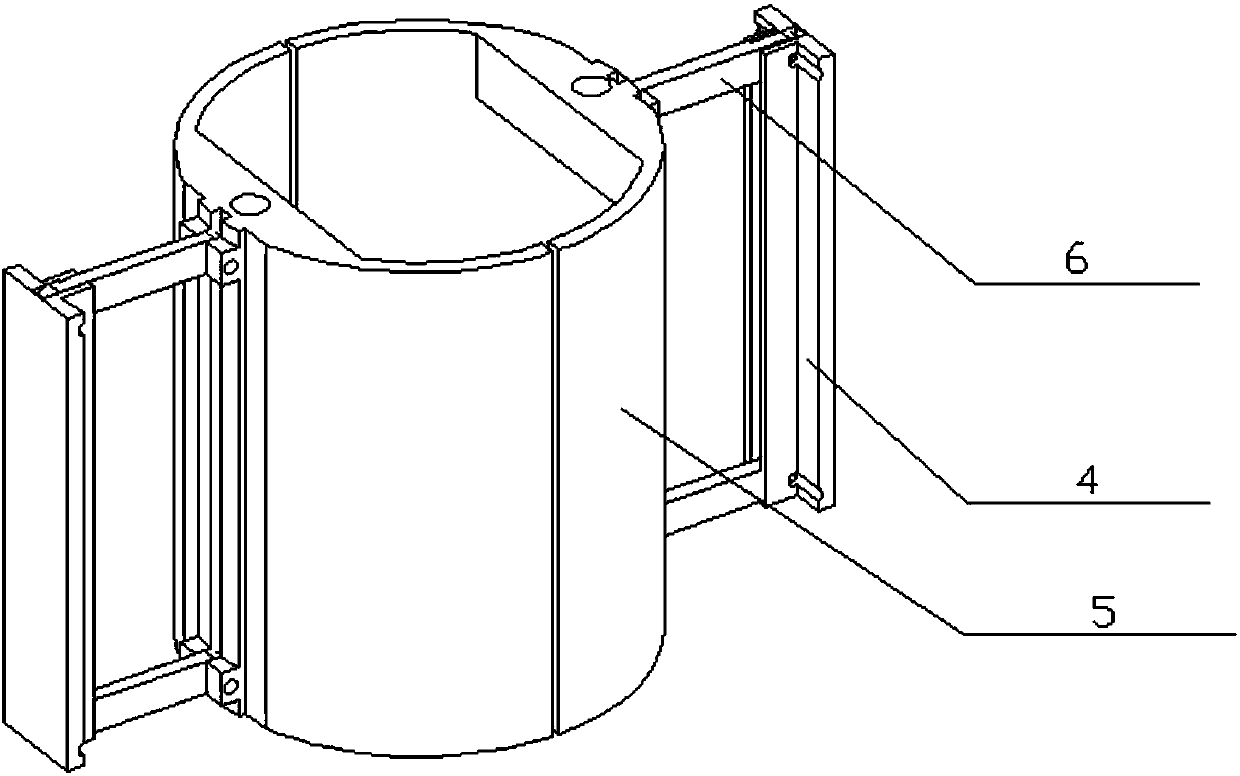

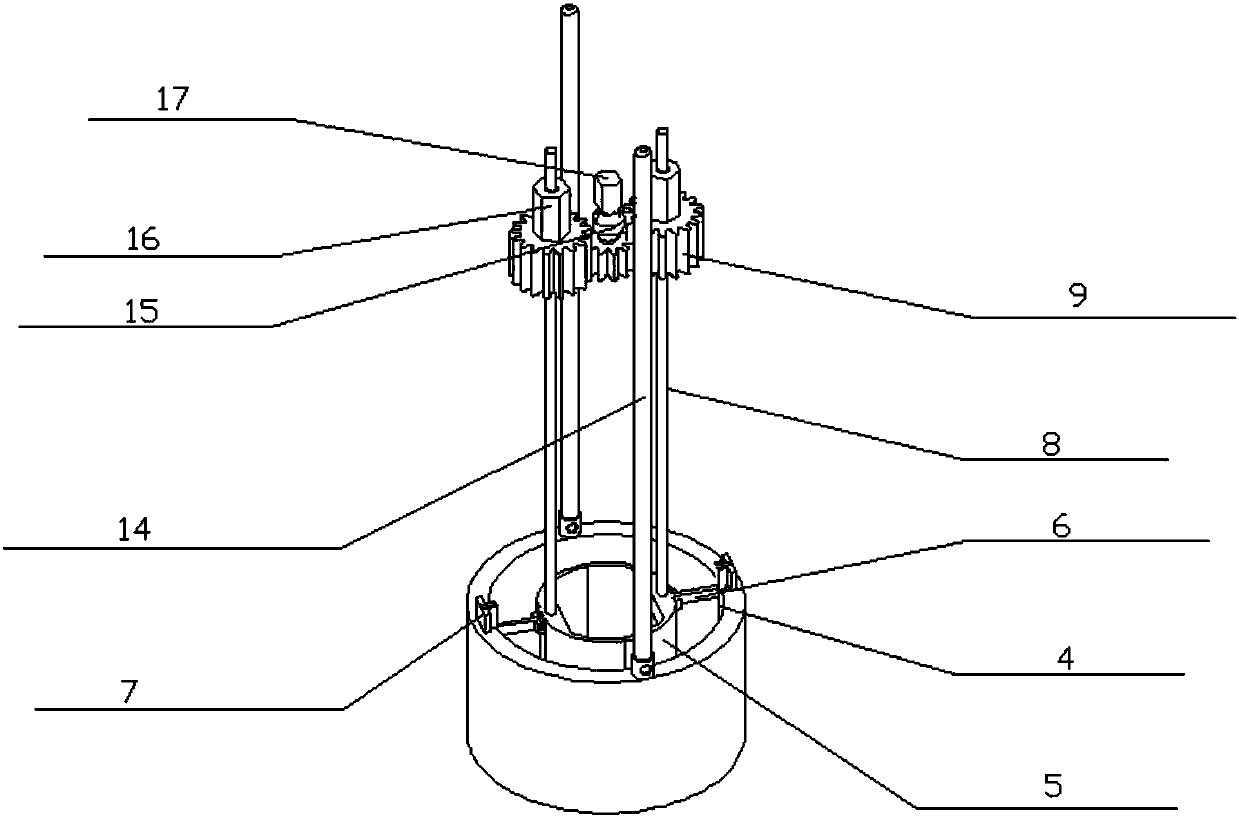

[0010] A device for automatically stacking optical discs and placing single and multiple sheets is composed of a pickup turntable 1, a central shaft 13 and a placement turntable 12. The pickup turntable 1 and the placement turntable 12 are installed on both sides of the central shaft 13, respectively, The pick-up turntable 1 is composed of the disc placement seat 2. The five disc placement seats 2 are evenly distributed on the pickup turntable 1. The central axis 13 is composed of the pick-up hand 5, the pick-up hand housing 3, the pick-up moving rod 14, and the pick-up pressing rod 6. Composed of pressure reducing slide 4, locking slider 7, pressure screw 8, pressure nut 16, transmission gear 9, coupling 15 and motor 17, the front end of the central shaft 13 passes through the picking moving rod 14 and the picker housing 3 is connected by bolt connection, the picking hand 5 is hinged with the picking press bar 6, the picking press bar 6 is hinged with the decompression slide ba...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap