Automatic flanging device for cloth

A hemming device and fabric technology, applied in the fields of sewing machines and embroidery machines, can solve the problems of uneven quality, low overall efficiency, time-consuming and labor-intensive problems, and achieve the effects of reducing production costs, improving production efficiency, and reducing technical levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

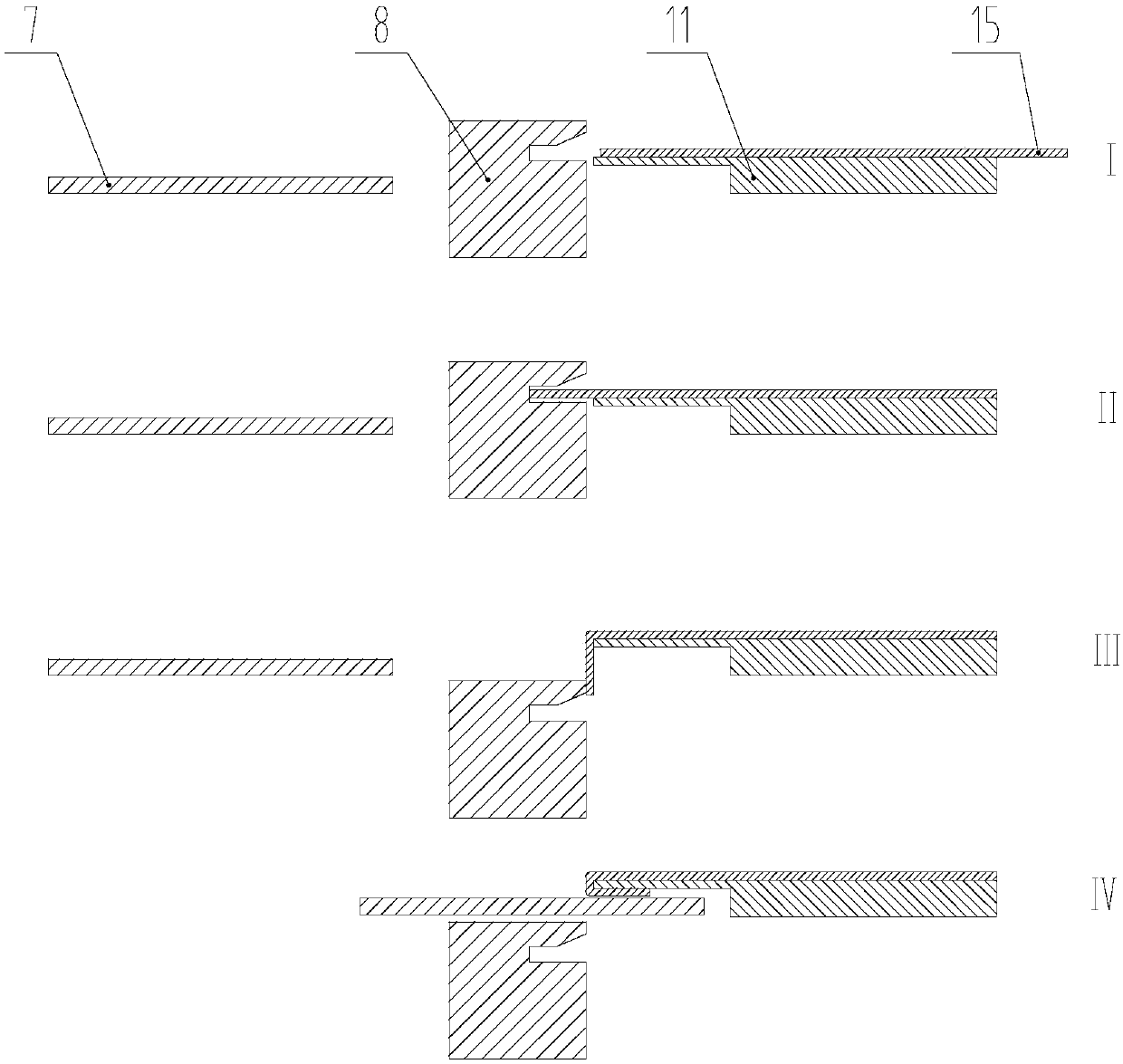

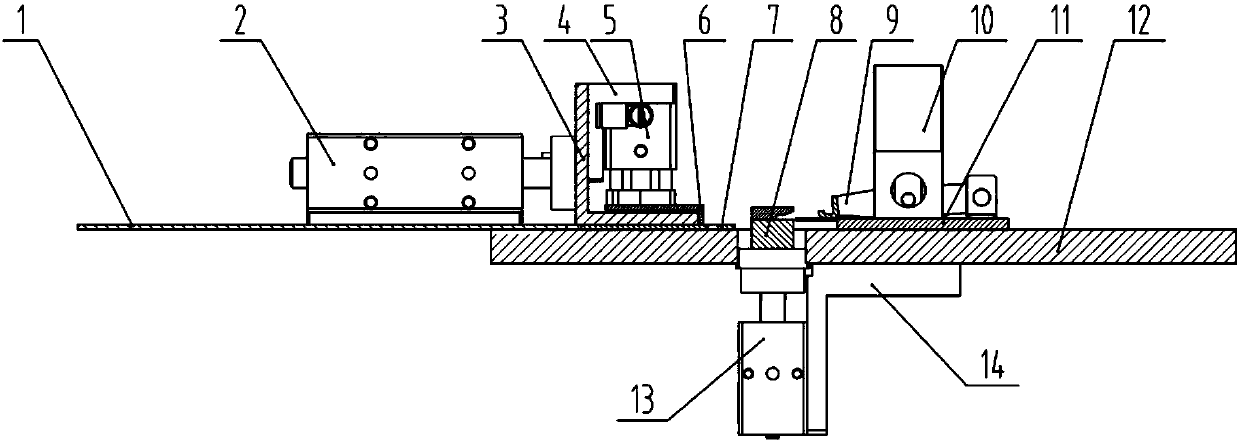

[0012] The present invention will be further described below in conjunction with the accompanying drawings: an automatic fabric folding device, including a supporting plate 1, a push-pull cylinder 2, a push-pull angle steel 3, a mounting seat 4, a cloth pressing cylinder b5, a cloth pressing strip 6, a push plate 7, and a pull block 8. Cloth pressing rod 9, cloth pressing cylinder a10, support plate 11, platen 12, lifting cylinder 13, lifting cylinder mounting seat 14, cloth 15; the lifting cylinder is fixed on the lifting cylinder mounting seat and fixed on the table board.

[0013] The push-pull cylinder 2 is fixed on the supporting plate 1 and connected with the push-pull angle steel 3; the push-pull angle steel 3 is connected with the push plate 7.

[0014] The cloth pressing cylinder b5 is fixed on the push-pull angle steel 3 through the mounting seat 4, and is connected with the cloth pressing bar 6, and the cloth pressing bar 6 can be controlled up and down by the pushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com