Self-cleaning sewage treatment unit

A sewage treatment, self-cleaning technology, applied in water/sewage treatment, water/sludge/sewage treatment, feeding/discharging device of sedimentation tank, etc. It can reduce the labor intensity, improve the convenience of cleaning, and improve the effect of sedimentation and decontamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

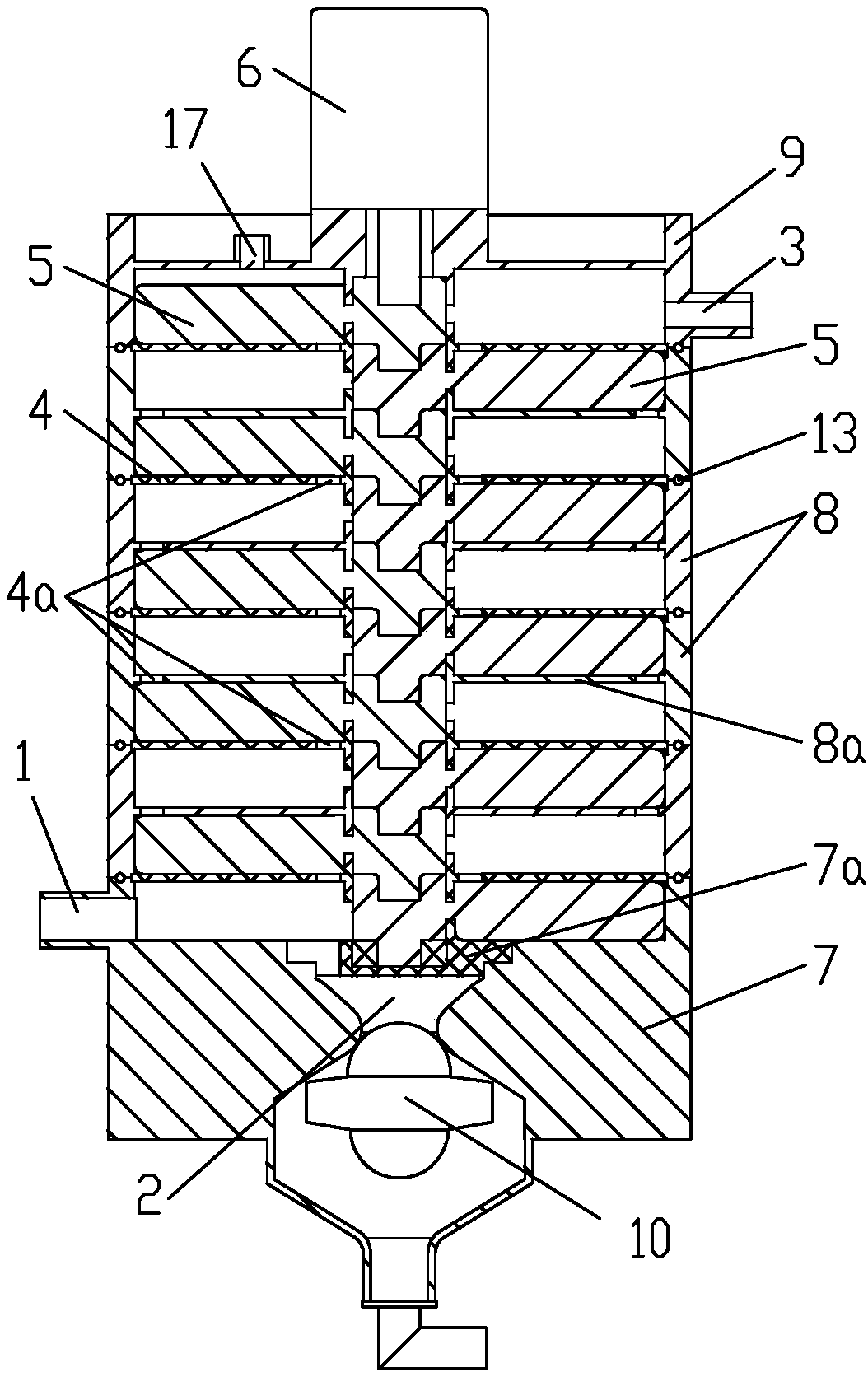

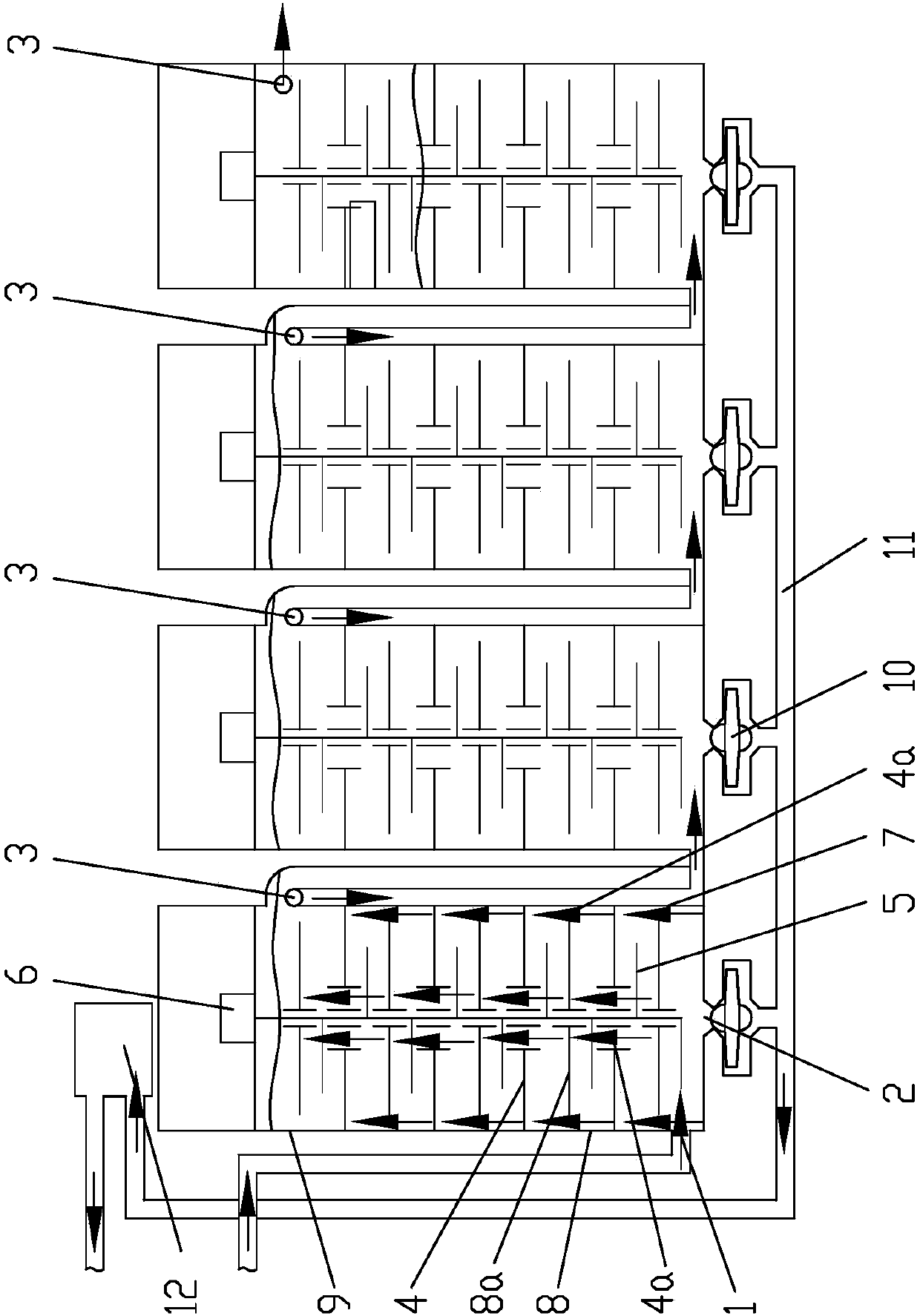

[0017] see figure 1 , a self-cleaning sewage treatment unit, including a container for sedimentation and separation; the container is in a barrel-shaped structure, the lower part of the container is provided with a water inlet 1 and a sewage outlet 2, and the upper part is provided with a water outlet 3; the inside of the container is distributed up and down A plurality of clapboards are divided into several sedimentation separation areas, and the adjacent sedimentation separation areas are connected through the water distribution holes 4a provided on the clapboard; the container is provided with a rotary cleaning device driven by a power source 6, and the rotary cleaning device is used for The sediment is cleaned by rotation of a plurality of cleaning members 5 respectively located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com