Self-cleaned circulation water tank for cleaning machine

A technology of circulating water tank and washing machine, which is applied in multi-stage water treatment, water/sewage treatment, water/sludge/sewage treatment, etc. The effect of sedimentation and decontamination, the effect of reducing labor intensity and improving the convenience of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings, but the present invention is not limited to the scope of the described embodiments.

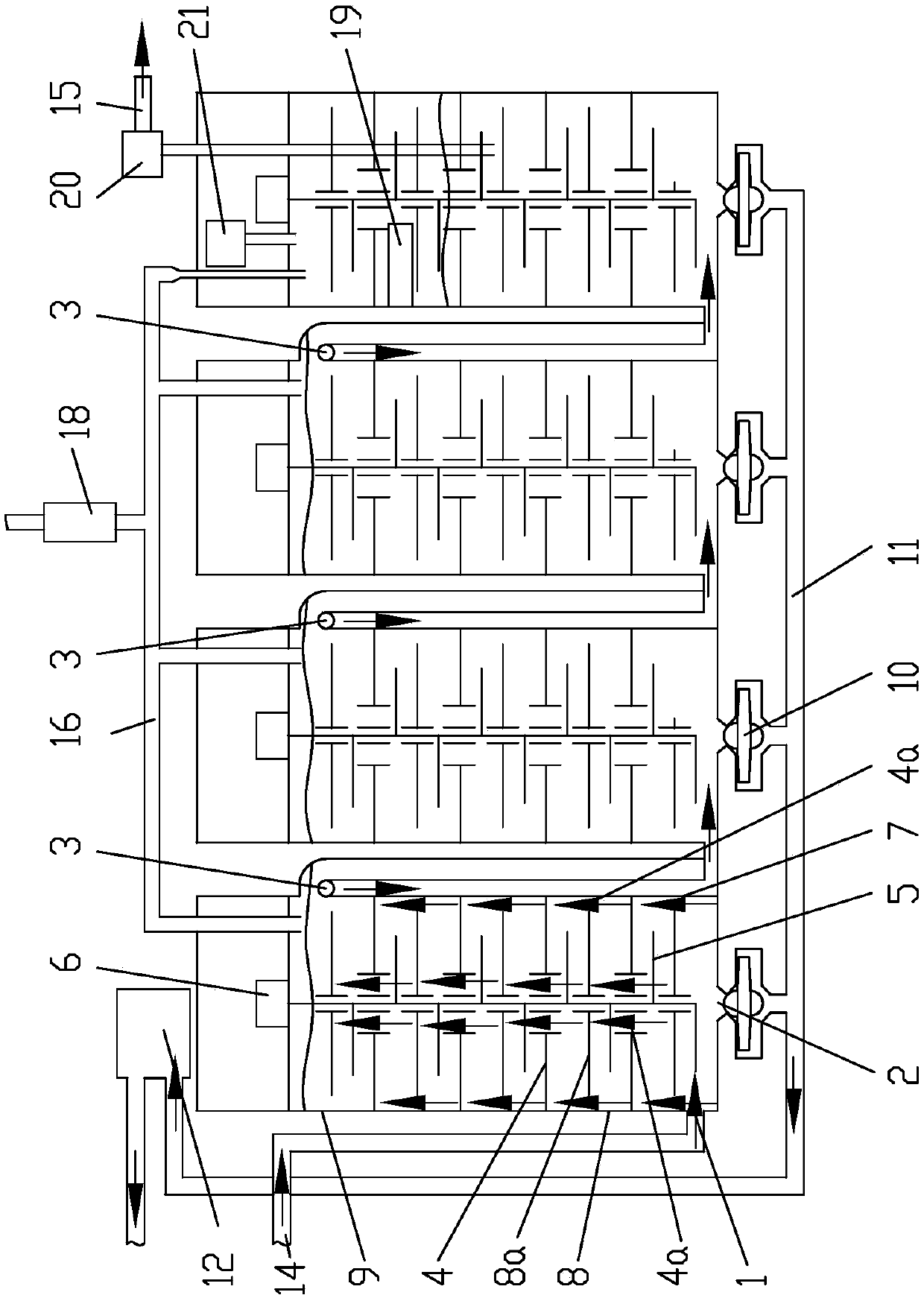

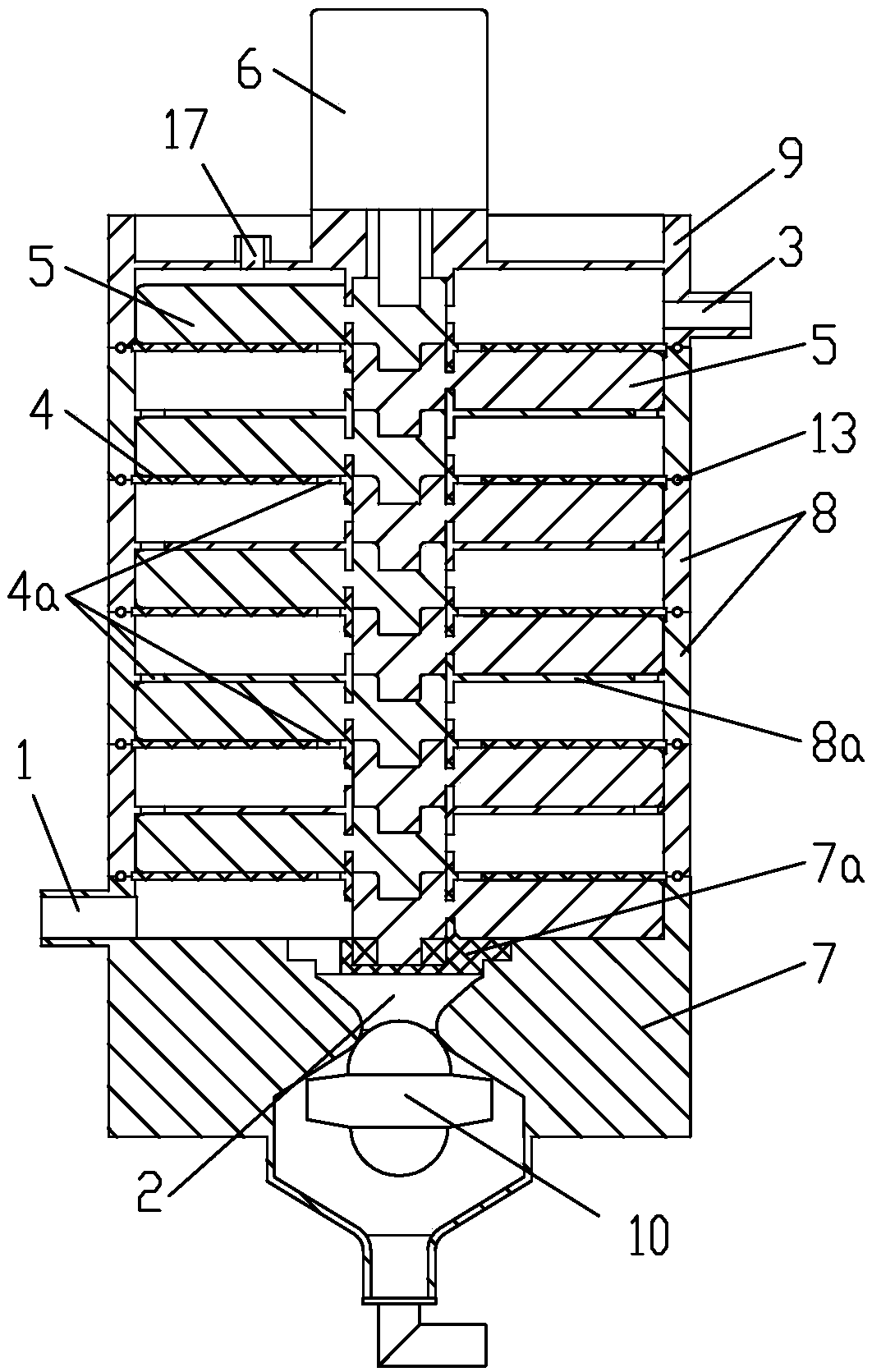

[0020] See figure 1 , figure 2 , A self-cleaning circulating water tank for a washing machine, comprising a return pipe 14, a water supply pipe 15, and a sewage treatment system; the sewage treatment system includes a plurality of sewage treatment units connected in sequence with sedimentation separation, and the sewage treatment unit is provided with sedimentation separation The barrel-shaped container is provided with a water inlet 1, a sewage outlet 2 and a water outlet 3; a plurality of vertically distributed settling areas connected in sequence are formed in the container; a rotating cleaning device driven by a power source 6 is also provided in the container , The rotary cleaning device is used to clean the sediment through a plurality of cleaning members 5 respectively located in each settling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com