Manufacturing apparatus for making articles made of light alloys

A technology for manufacturing devices and light alloys, which is applied in the field of device devices and can solve the problems of not very compact structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

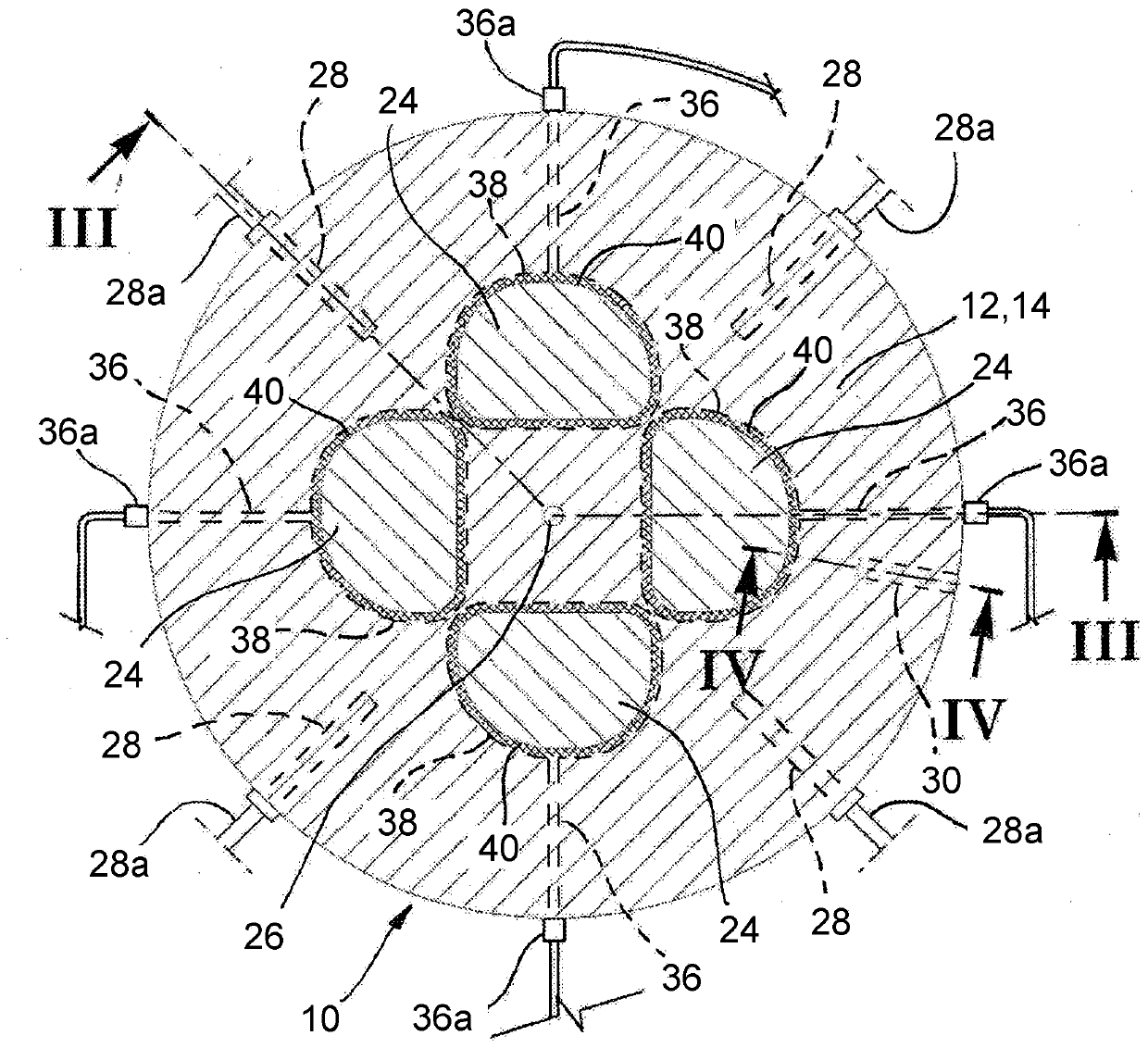

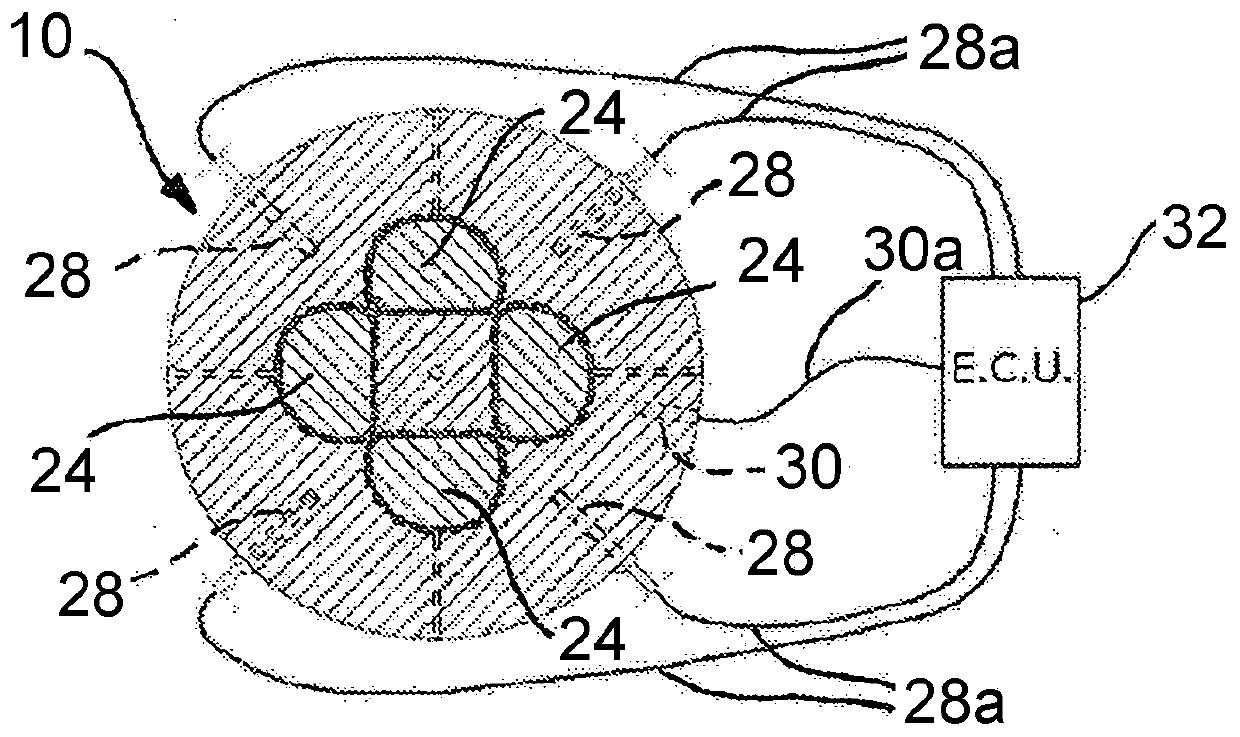

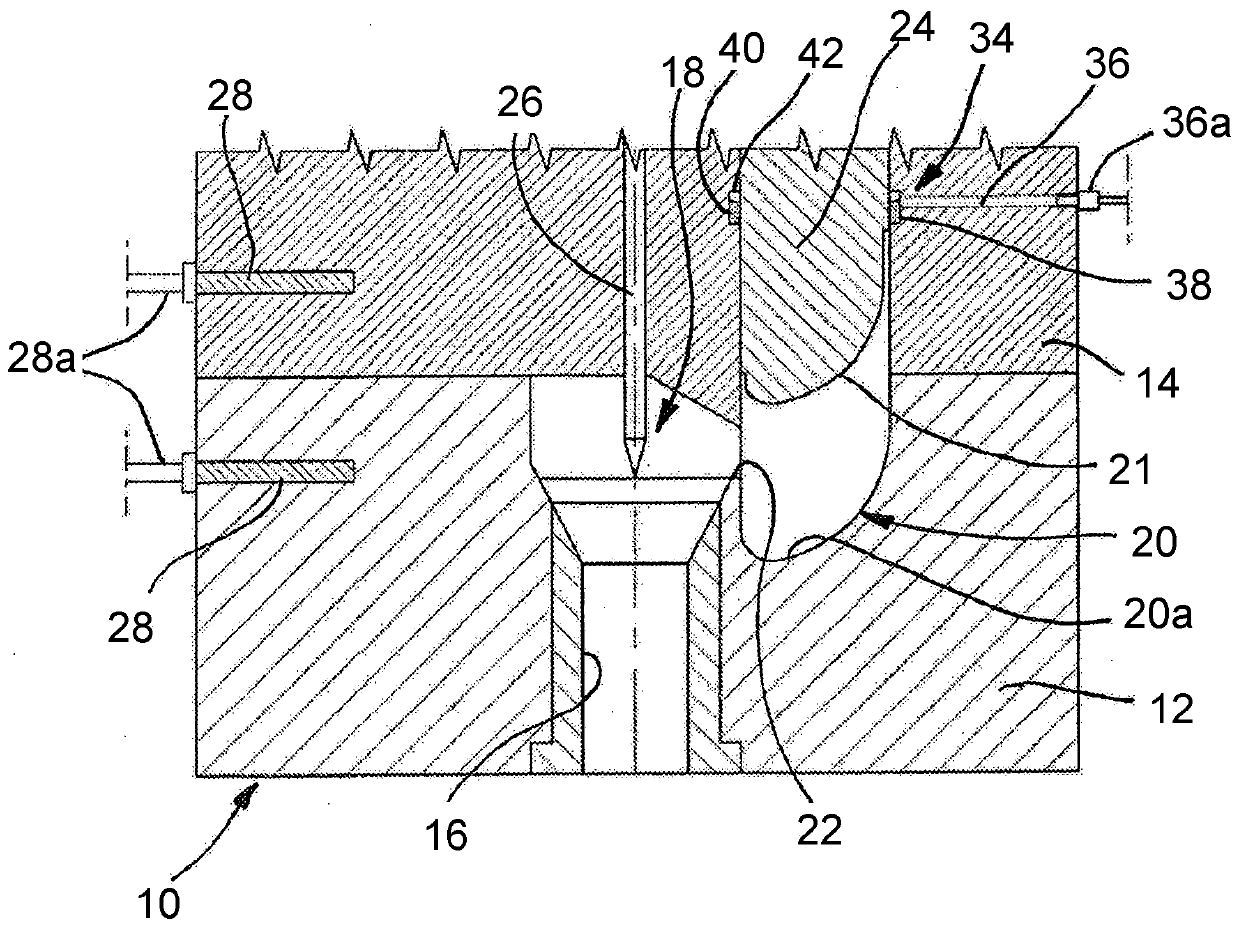

[0017] With reference to the drawings, the device according to the invention for the manufacture of articles of light alloy or similar material comprises a mold, indicated in its entirety by the reference numeral 10 . Purely by way of example, the apparatus shown in the figures will manufacture multiple toe caps for safety shoes in a single molding operation.

[0018] The mold 10 comprises a lower mold half 12 and an upper mold half 14 , both metallic, capable of being joined together in the closed configuration of the mold 10 .

[0019] In particular, the lower mold half 12 will be detachably fixed on a support plane determined by a press (not shown in the figures, since it is of a known type per se) which enables the upper mold half 14 to be placed on the mold 10. The vertical movement during the closing and opening steps of the mold simultaneously applies pressure to the two halves of the mold.

[0020] The lower half-mold 12 is passed at a substantially central position b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com