Finely adjustable fixing device

A fixer and connecting pipe technology, applied in the field of fine-tuning fixers, can solve problems such as unsafe hazards, cargo rolling, vibration, etc., and achieve the effects of stable and reliable force-bearing structure, good fixation effect, and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

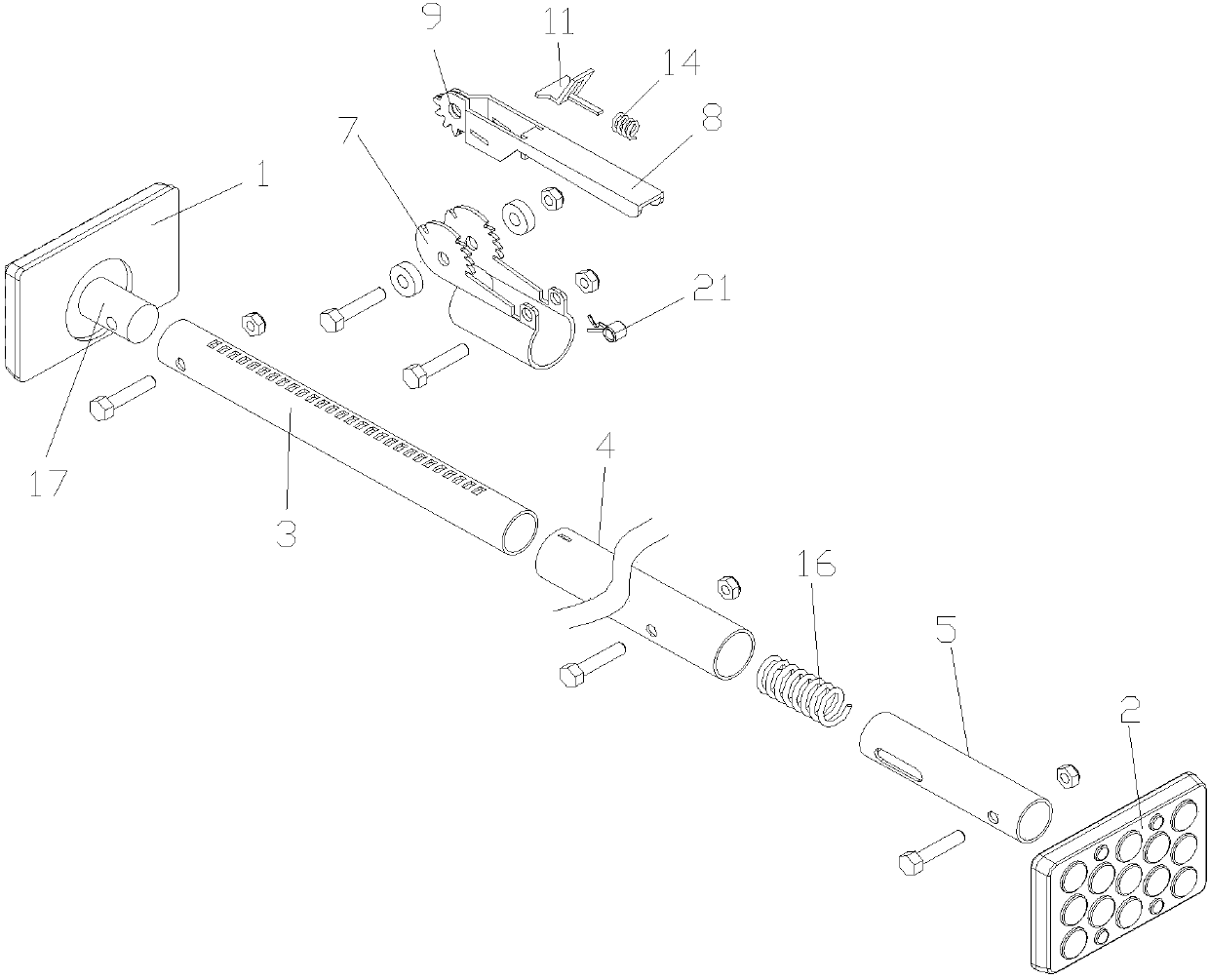

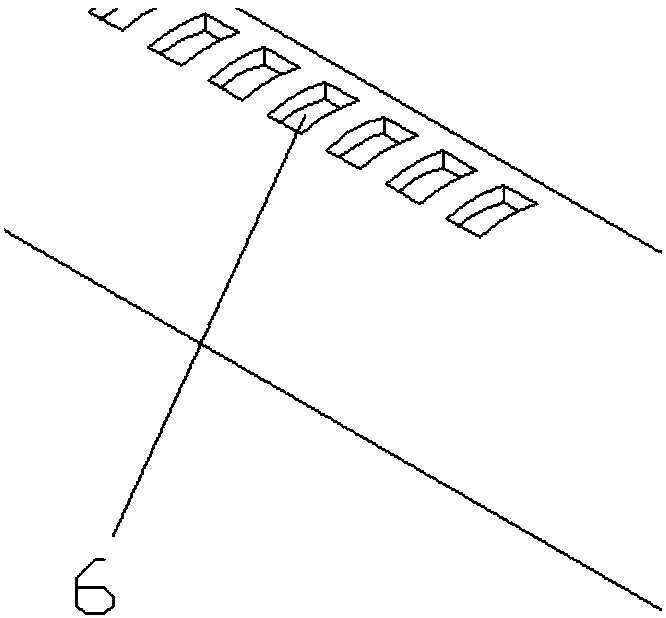

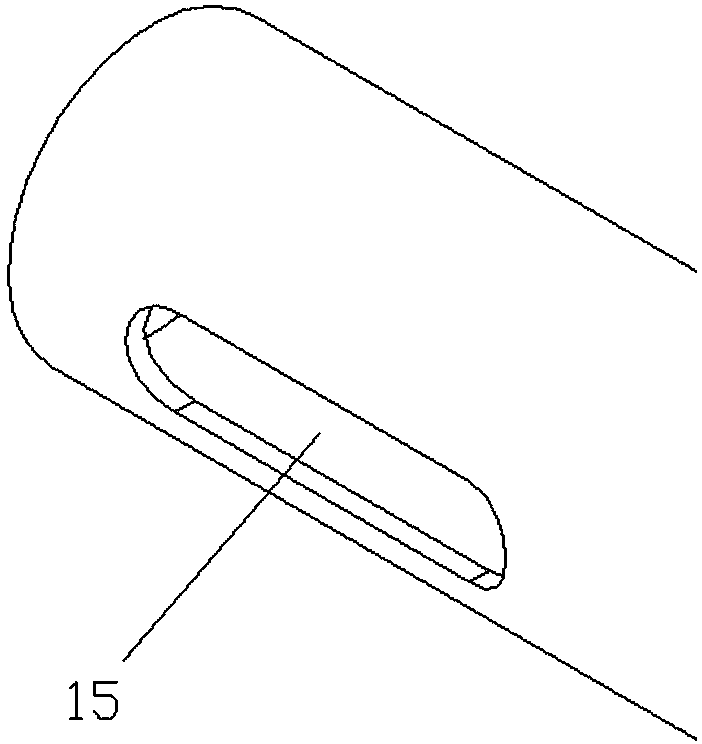

[0031] Such as Figure 1-6As shown, a finely adjustable fixer includes a left plate 1, a right plate 2, a left pipe 3 and a connecting pipe 4, the left plate 1 and the right plate 2 are respectively connected with the left pipe 3 and the connecting pipe 4, and the left One end of the pipe 3 is inserted into the connecting pipe 4, the left pipe 3 is slidingly connected with the connecting pipe 4, the left pipe 3 is provided with a clamping hole 6, the outer surface of the connecting pipe 4 has a connecting body 7, and the connecting body 7 A connecting piece 8 is provided on the top, and the connecting piece 8 is rotatably connected with the connecting body 7. The end of the connecting piece 8 is provided with a ratchet 9 matched with the card hole 6. The left tube 3 and the connecting tube 4 pass through the card hole 6 and the ratchet 9 limit, the connecting piece 8 is provided with a guide groove 10 and a trigger 11, the trigger 11 is provided with a sliding part 12, the sli...

Embodiment 2

[0034] Such as Figure 1-6 As shown, a finely adjustable fixer includes a left plate 1, a right plate 2, a left pipe 3, a connecting pipe 4 and a right pipe 5, and the left plate 1 and the right plate 2 are threaded with the left pipe 3 and the right pipe 5 respectively. connection, one end of the left pipe 3 is inserted into the connecting pipe 4, the left pipe 3 is slidingly connected with the connecting pipe 4, the left pipe 3 is provided with a clamping hole 6, and the outer surface of the connecting pipe 4 has a connecting body 7, The connecting body 7 is provided with a connecting piece 8, the connecting piece 8 is rotatably connected with the connecting body 7, the end of the connecting piece 8 is provided with a ratchet 9 matched with the card hole 6, the left pipe 3 and the connecting pipe 4. The position is limited by the card hole 6 and the ratchet 9. The connecting piece 8 is provided with a guide groove 10 and a trigger 11. The trigger 11 is provided with a slidin...

Embodiment 3

[0037] Such as Figure 1-7 As shown, a finely adjustable fixer includes a left plate 1, a right plate 2, a left pipe 3, a connecting pipe 4 and a right pipe 5, one end of the left pipe 3 is inserted into the connecting pipe 4, and the left pipe 3 is connected to the The tube 4 is slidingly connected, the left tube 3 is provided with a card hole 6, the outer surface of the connecting tube 4 has a connecting body 7, and the connecting body 7 is provided with a connecting piece 8, and the connecting piece 8 and the connecting body 7 Rotational connection, the end of the connecting piece 8 is provided with a ratchet 9 matched with the card hole 6, the left pipe 3 and the connecting pipe 4 are limited by the card hole 6 and the ratchet 9, and the connecting piece 8 is provided with a guide groove 10 And the trigger 11, the trigger 11 is provided with a sliding part 12, the sliding part 12 is inserted into the guide groove 10, the trigger 11 is slidably connected with the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com