Conveniently-used hardware conveying basin

A hardware and convenient technology, which is applied in the direction of transportation and packaging, rigid containers, containers, etc., can solve the problems of easily damaged screw threads, increased screw collision friction, large manpower, etc., to achieve protection from bumps, reduce impact force, reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

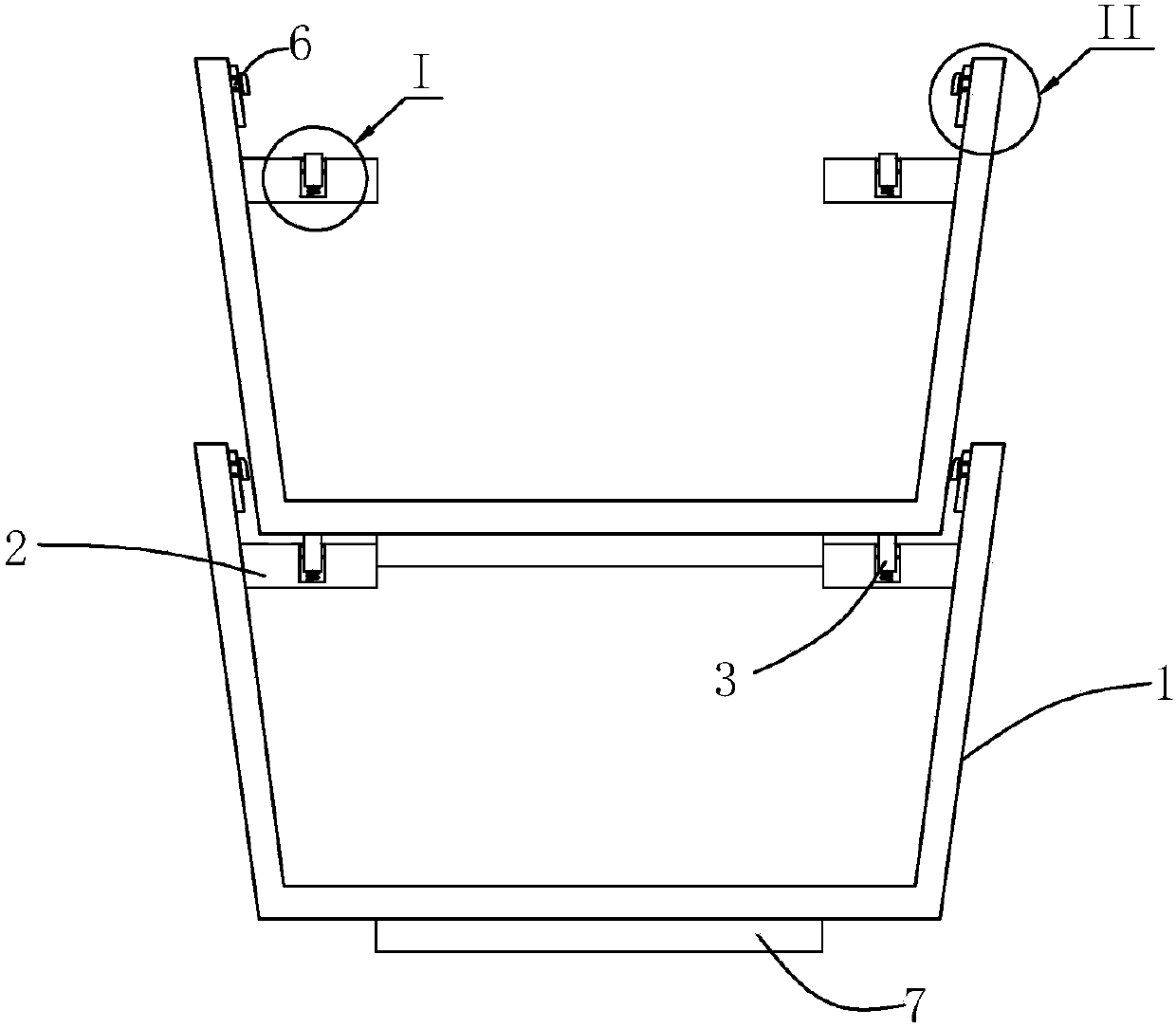

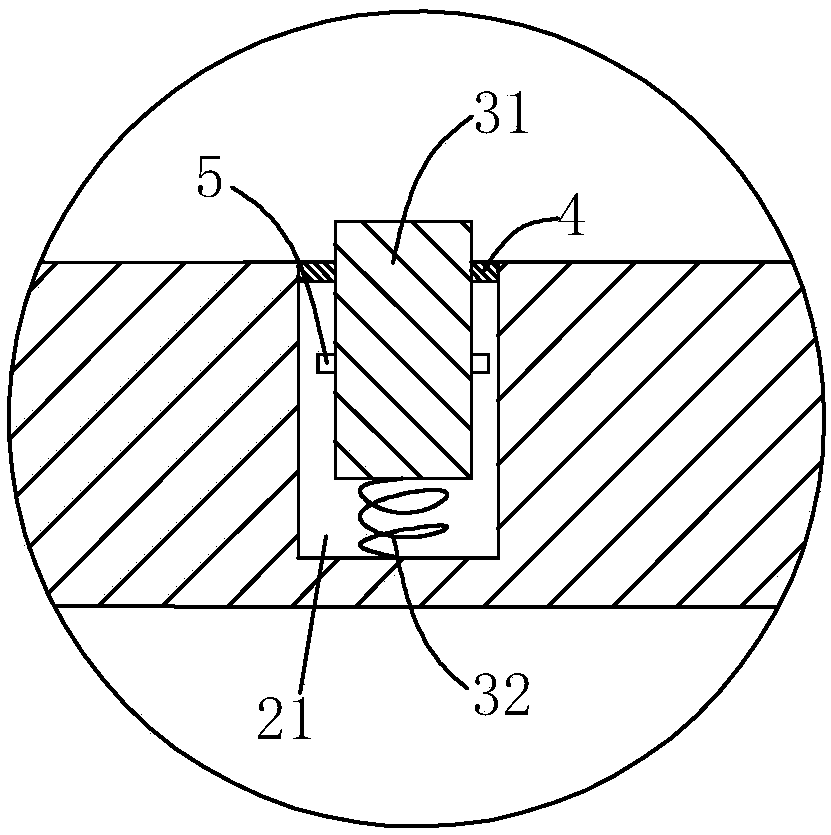

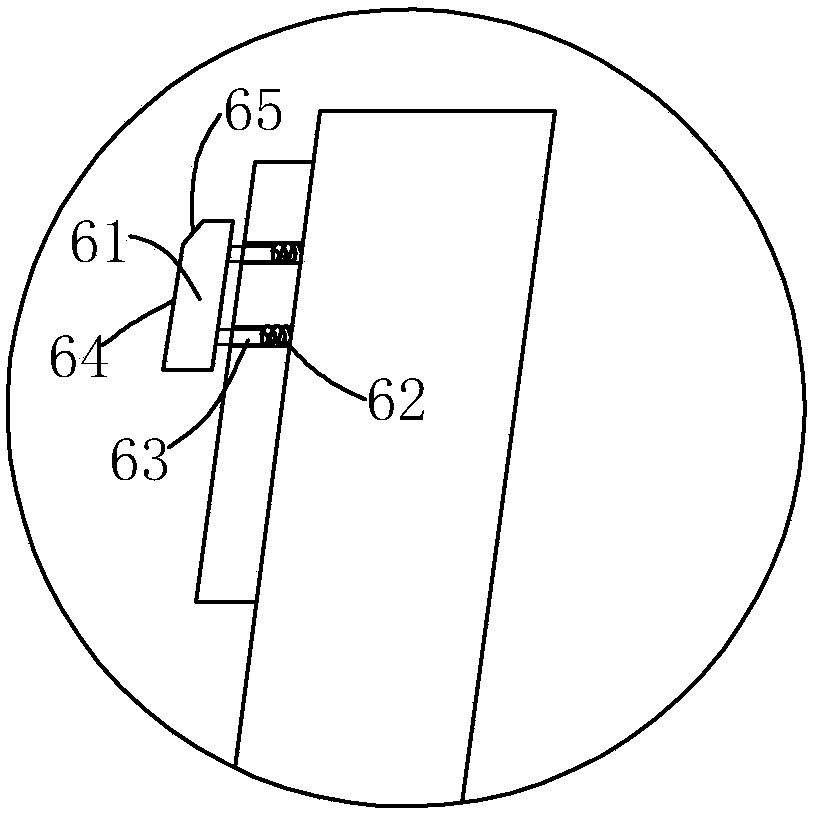

[0016] refer to Figure 1 to Figure 2 , an easy-to-use hardware handling basin of the present invention, comprising a basin body 1, said basin body 1 is flared from bottom to top, and a support member 2 is horizontally arranged on the inner wall of said basin body 1, and said support An elastic assembly 3 is provided on the member 2, and the elastic assembly 3 is used to support the bottom of the basin body 1. The support member 2 is an annular support plate surrounding the basin body 1. The elastic assembly 3 is provided with a plurality of , and the circumferential direction is evenly arranged on the support plate. When in use, the upper basin 1 can be supported on the elastic component 3 of the lower basin 1, and will not support all the weight in the hardware of the lower basin 1, especially the threaded hardware, which can effectively avoid During the process, the hardware is damaged; in addition, the upper basin body 1 and the lower basin body 1 are in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com