Zero-value error calibration device for construction project quality detector

A construction engineering and error calibration technology, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of affecting the calibration effect, the inability to calibrate the zero value error of the quality detector, and the quality deviation of the quality detector to the construction project, etc. , to avoid calibration errors and improve the calibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

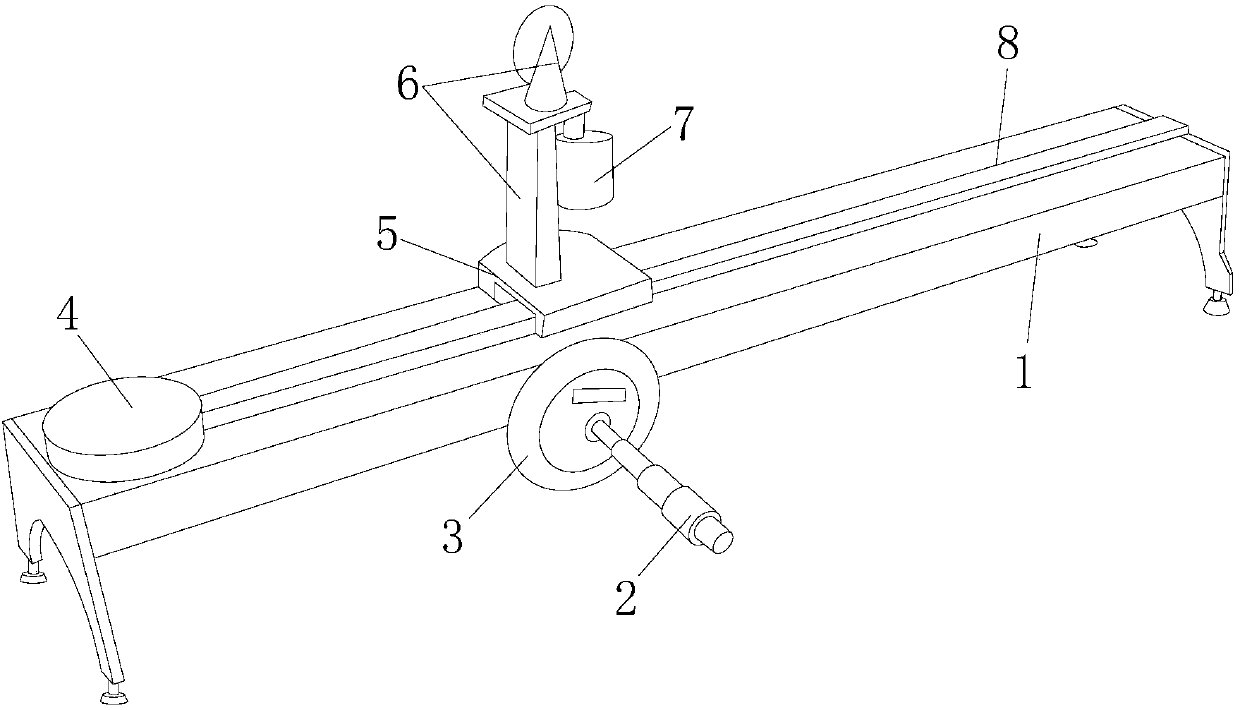

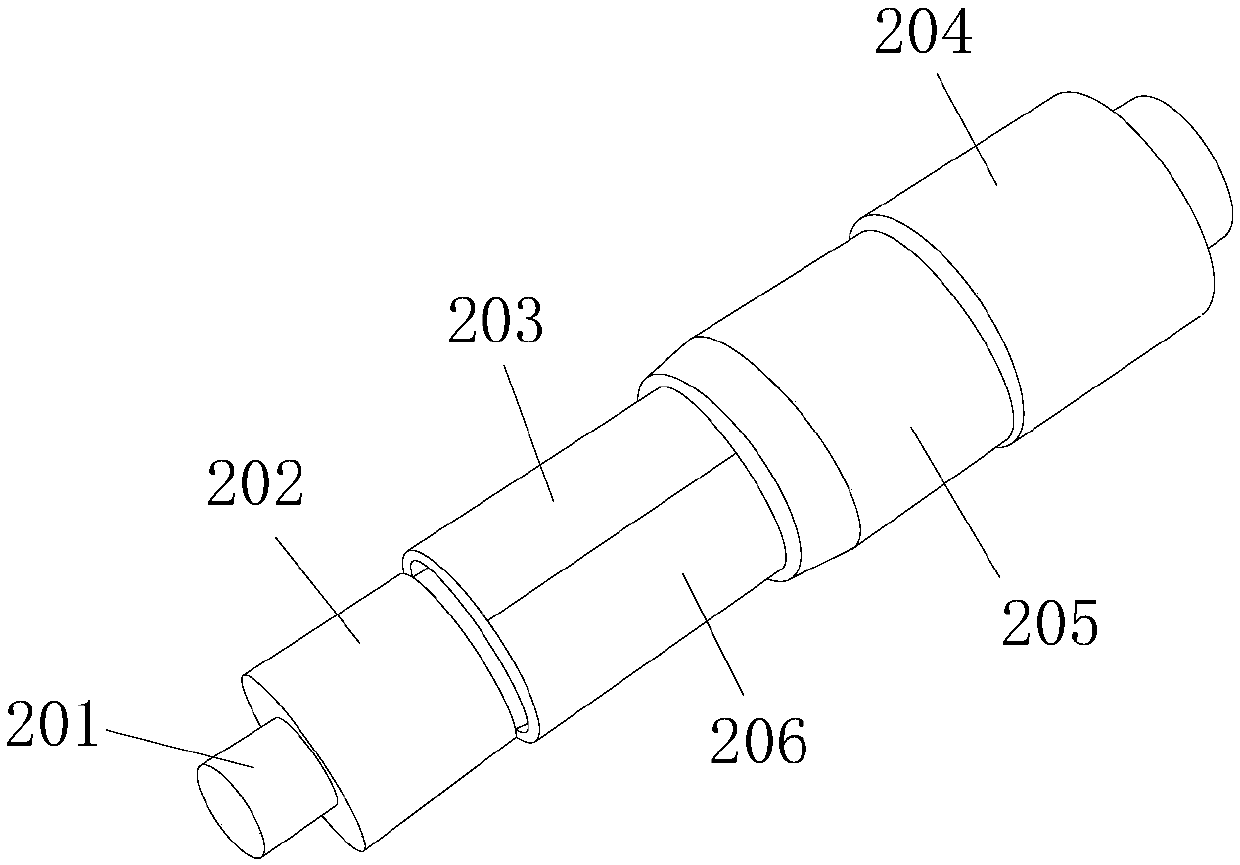

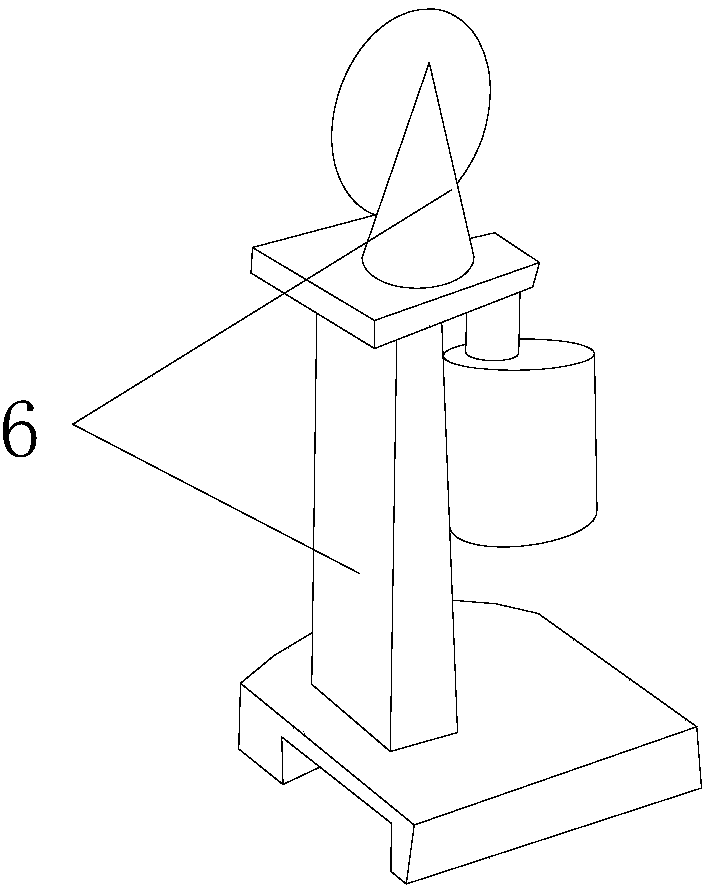

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution: a zero-value error calibration device for construction quality detectors, the structure of which includes a base 1, a trimmer 2, a mounting plate 3, a turntable 4, a slider 5, a support frame 6, Calibrator main body 7, guide rail 8, the base 1 is N-shaped with equal surfaces on both sides and concave bottom, the top surface and the bottom surface of the slider 5 are movably connected by interference fit and form a convex shape, the height of both sides of the base 1 It is 15cm, and the support frame 6 is T-shaped with equal surface on both sides of the top and an extended bottom. The top surface and the bottom surface of the slider 5 are movably connected by inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap