Pipeline cavitation cleaning effect detecting system

A technology of cleaning effect and detection system, which is applied in the direction of measuring devices, cleaning hollow objects, cleaning methods and utensils, etc., which can solve the problems of cavitation phenomenon that cannot be detected, quantitative and regional detection, and cavitation phenomenon cannot be quantified, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

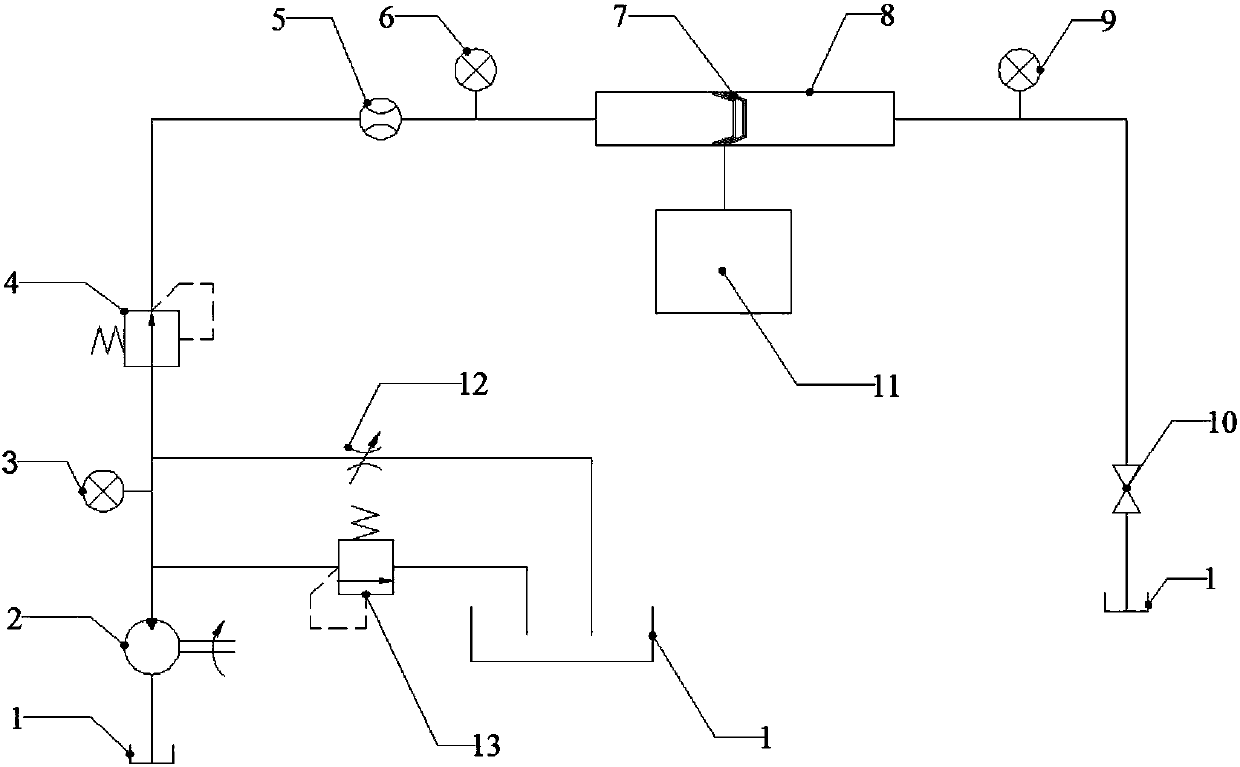

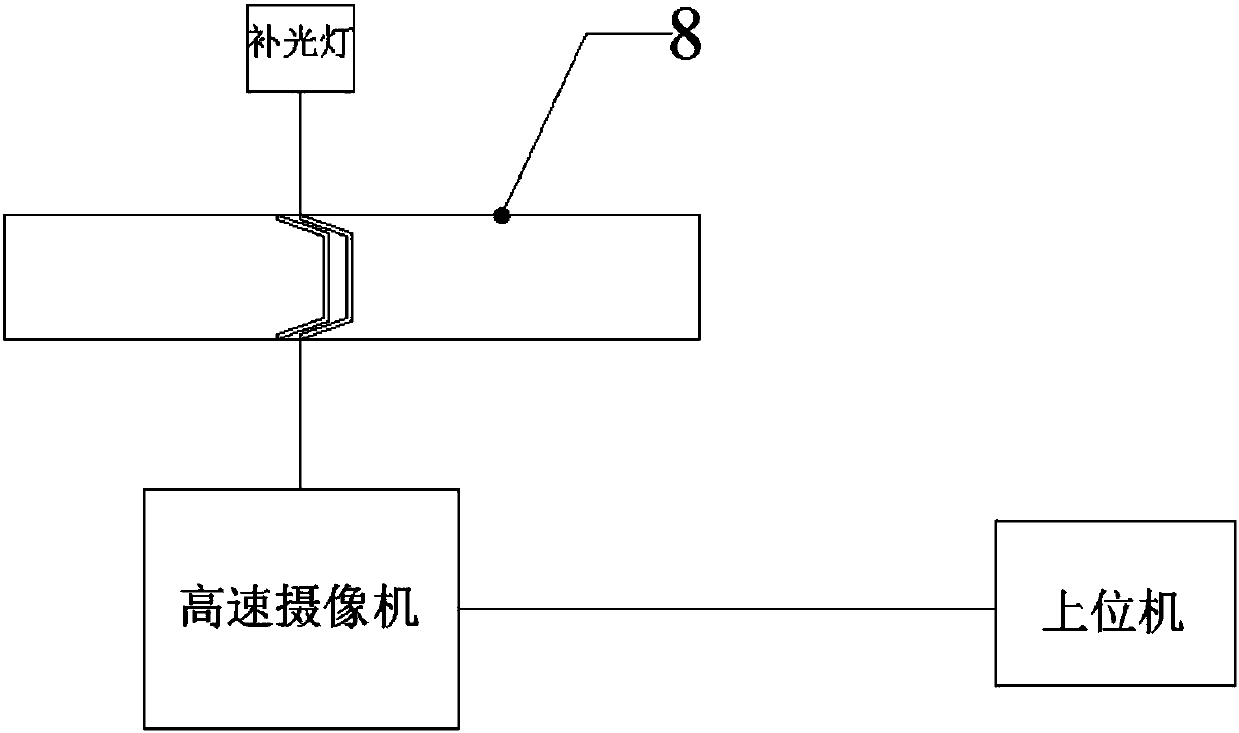

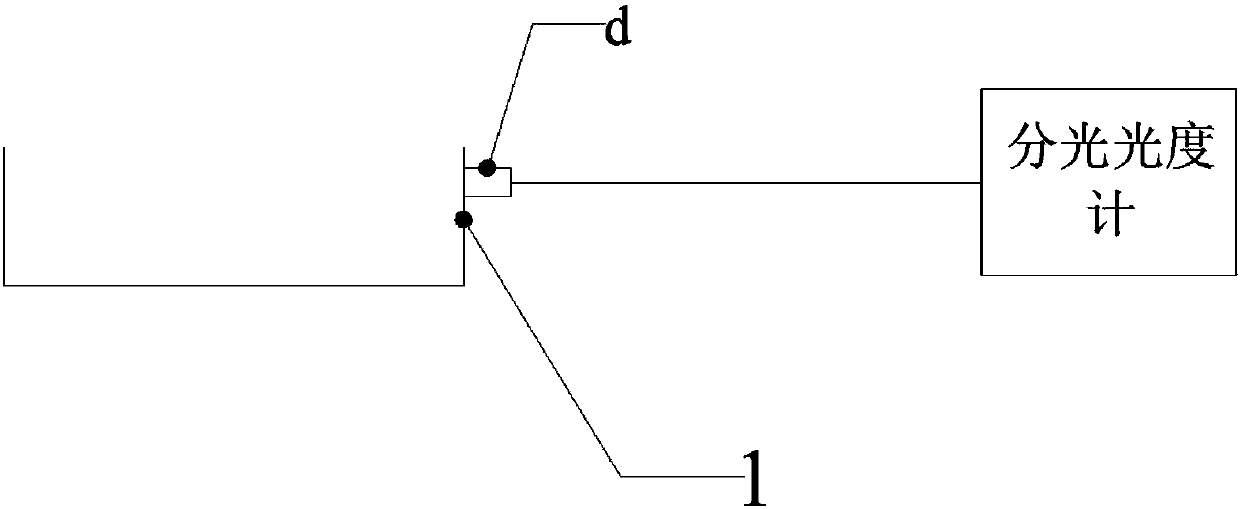

[0031] Such as Figure 1-4 As shown, the pipeline cavitation cleaning effect detection system includes a power unit, a control unit, an execution unit and a cavitation detection device 11;

[0032] The power unit includes a motor and a centrifugal pump 2, the centrifugal pump 2 and the motor are assembled together through a coupling, the water inlet of the centrifugal pump 2 is directly connected to the water tank 1, and the water outlet of the centrifugal pump 2 Connect with the control unit;

[0033] Described control unit comprises throttling valve 12, decompression valve 4 and safety overflow valve 13, and the water inlet end of described decompression valve 4 is connected with the water outlet end of centrifugal pump 2 through pressure gauge A3, and decompression valve 4 The water outlet end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com