Novel welding gun dragging detection mechanism

A detection mechanism and welding torch technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of welding quality and speed cannot be guaranteed, achieve good compactness, neat stator laminations, and improve production The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

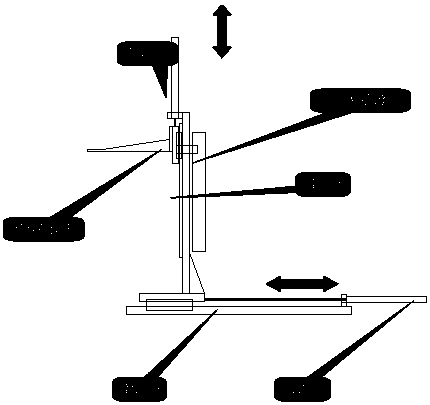

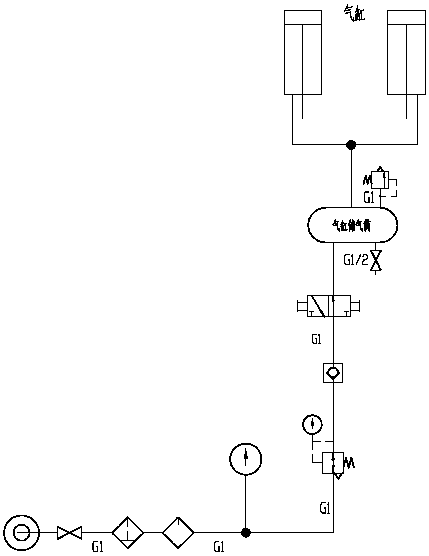

[0011] The present invention comprises a cylinder 1 and a slide table 1 arranged horizontally, the cylinder 1 drives the slide table 1 to move laterally, and a cylinder 2 and a slide table 2 arranged vertically are also provided, and the cylinder 2 drives the slide table 2 to move longitudinally. The slide table 2 is arranged on the slide table 1, and the slide table 2 is provided with a welding torch mounting seat and a displacement sensor.

[0012] The welding torch mounts and displacement sensors are arranged on different sides of the slide table 2 .

[0013] Said cylinder 1 and cylinder 2 are controlled by a frequency converter to operate electromagnetic valves arranged in cylinder 1 and cylinder 2 .

[0014] The cylinder 1 realizes the lateral movement of the slide table 1 through a ball screw, and the cylinder 2 realizes the longitudinal movement of the slide table 2 through a ball screw.

[0015] The invention is composed of two sliding tables, two cylinders, a displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com