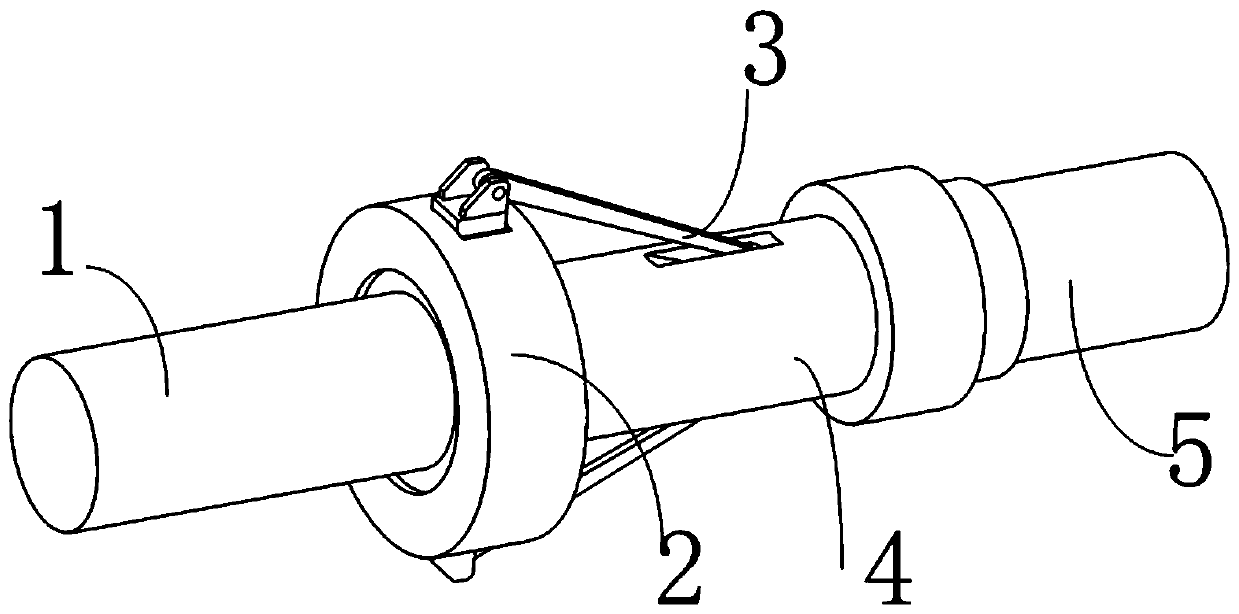

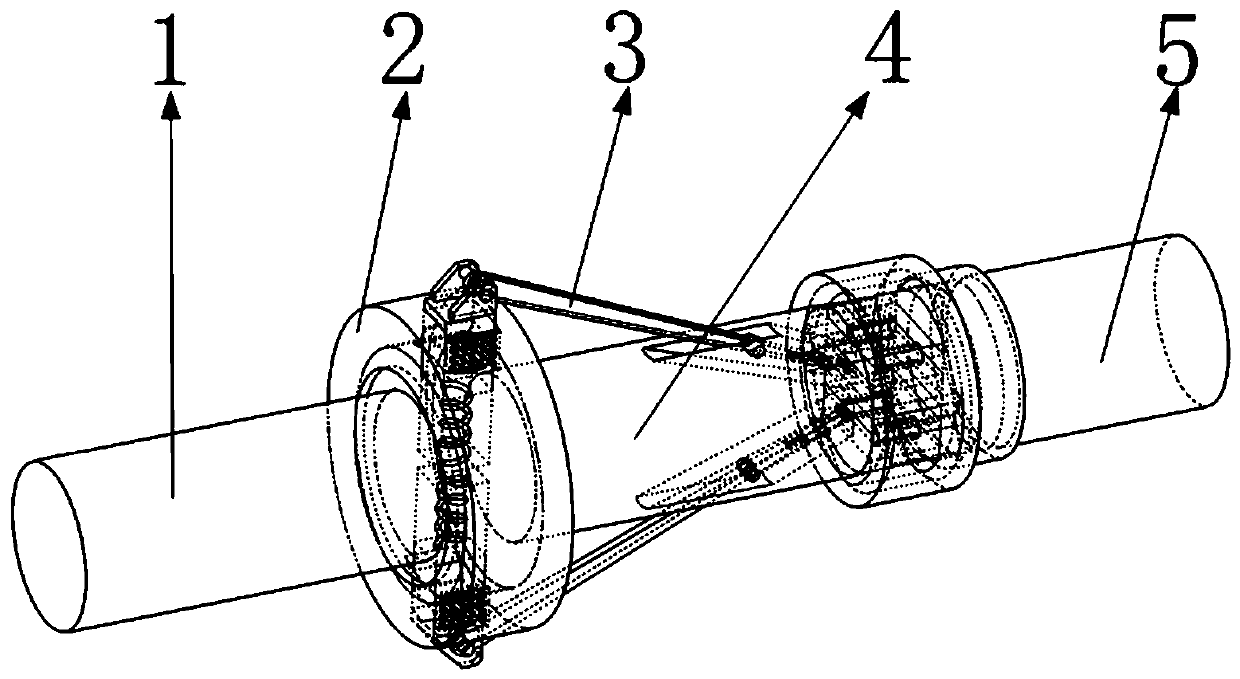

Two-way torque clutch based on centrifugation

A torque clutch, two-way technology, applied in the field of clutches, can solve problems such as limiting the development of mechanical business, the clutch cannot be adjusted, and the effect of the clutch is weakened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

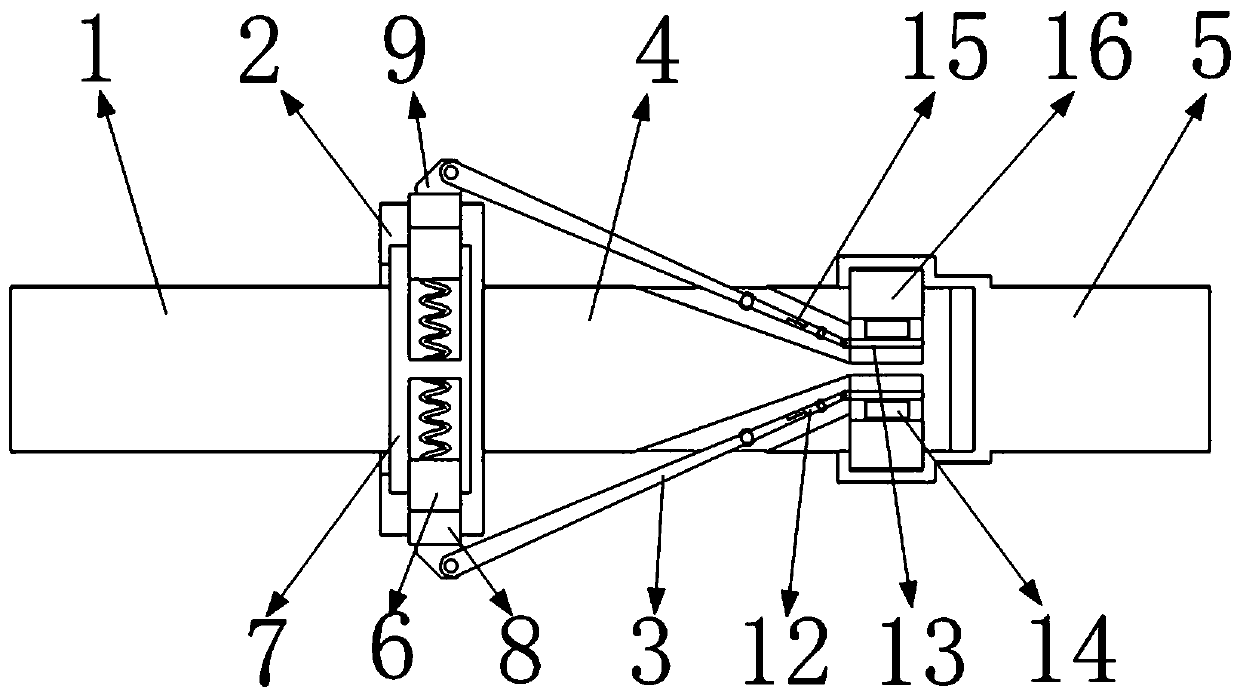

[0047] The specific embodiment: if people use the clutch designed by the present invention; when the input shaft 1 rotates; the input shaft 1 will drive the drive disc 7 to rotate; the drive disc 7 will rotate to make the centrifugal block 6 to the drive disc 7 outside Move; when the centrifugal block 6 is in contact with the arc surface on the drive slot 19 during the movement; one of the two centrifugal blocks 6 will move to the inside of the corresponding drive slot 19; the other centrifugal block 6 will Can not move to corresponding drive slot 19; The centrifugal block 6 that moves to drive slot 19 inboard in two centrifugal blocks 6 is in the moving process; This centrifugal block 6 can squeeze corresponding adjustment block 8; Make adjustment block 8 to Move away from the side of the drive plate 7; the movement of the adjustment block 8 will drive the corresponding first adjustment rod 3 to swing to the side away from the adjustment block 8 through the lugs on it; the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com