Four-rod mechanism and using method thereof

A four-bar mechanism and chain-rod technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve the problem of less application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

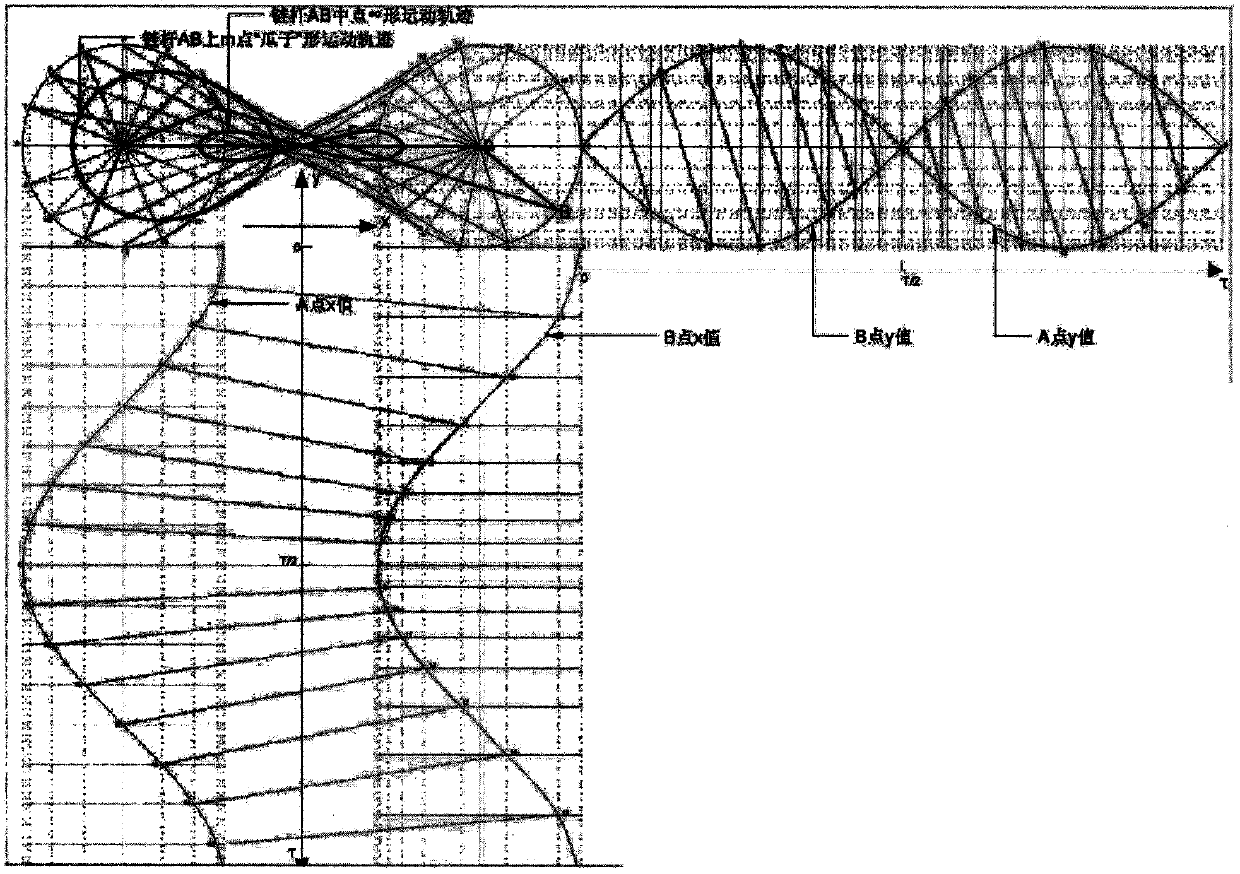

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

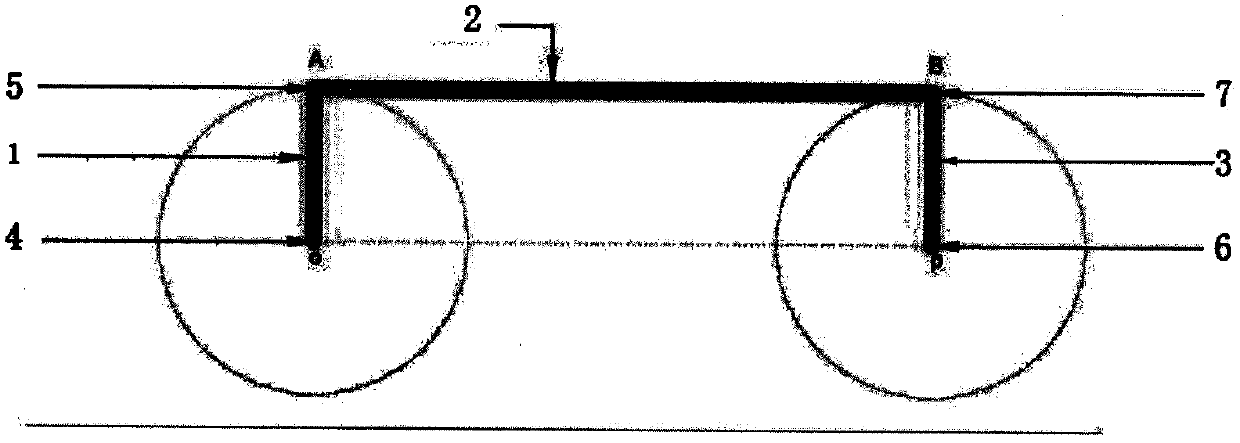

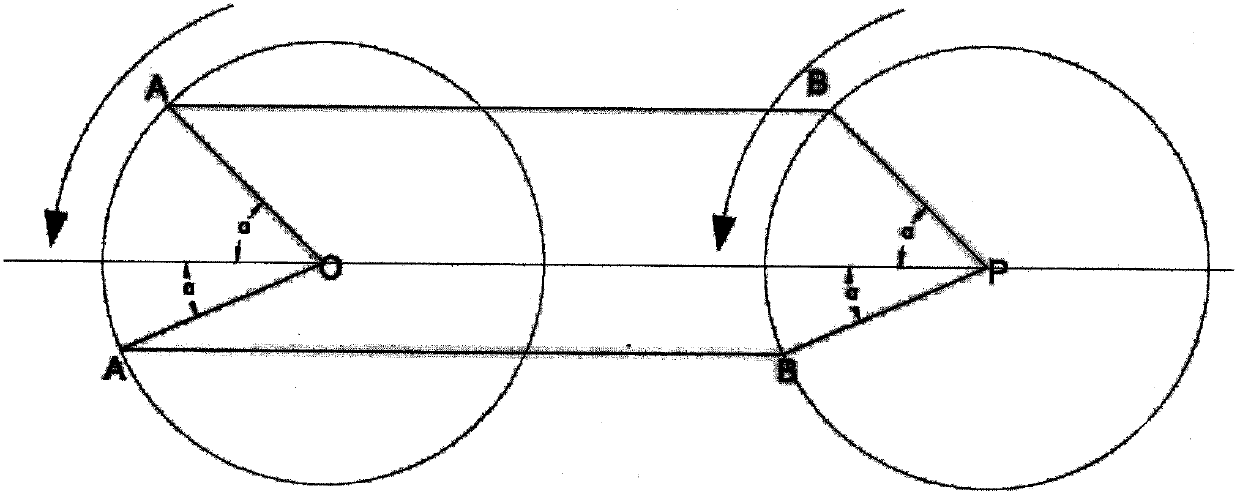

[0018] Such as figure 1 As shown, a four-bar mechanism can be widely used in mechanical equipment such as screening machines and fitness equipment, and is mainly used to realize biaxial orientation and cross motion. The four-bar mechanism includes a first chain bar 1, a second chain bar 2 and the third link 3, the two ends of the first link 1 are provided with a first fixed hinge point 4 and the first movable hinge point 5; the two ends of the third link 3 are provided with a second fixed hinge point 6 and the second movable hinge point 7; it should be noted that the first fixed hinge point 4 and the second fixed hinge point 6 are only relatively fixed in position, and its link (i.e. the first link 1 and the second link on the first fixed hinge point 4) The third link on the two fixed hinge points 6) can rotate 360° around the fixed hinge points. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com