Compact charging and baiting material feeding mechanism of bonder

A feeding mechanism, compact technology, applied in the field of bonding machine compact loading and unloading feeding mechanism, can solve the problems of large space size, large equipment footprint, etc., to achieve reduced size and space, low cost, and meet the travel schedule required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with embodiment accompanying drawing:

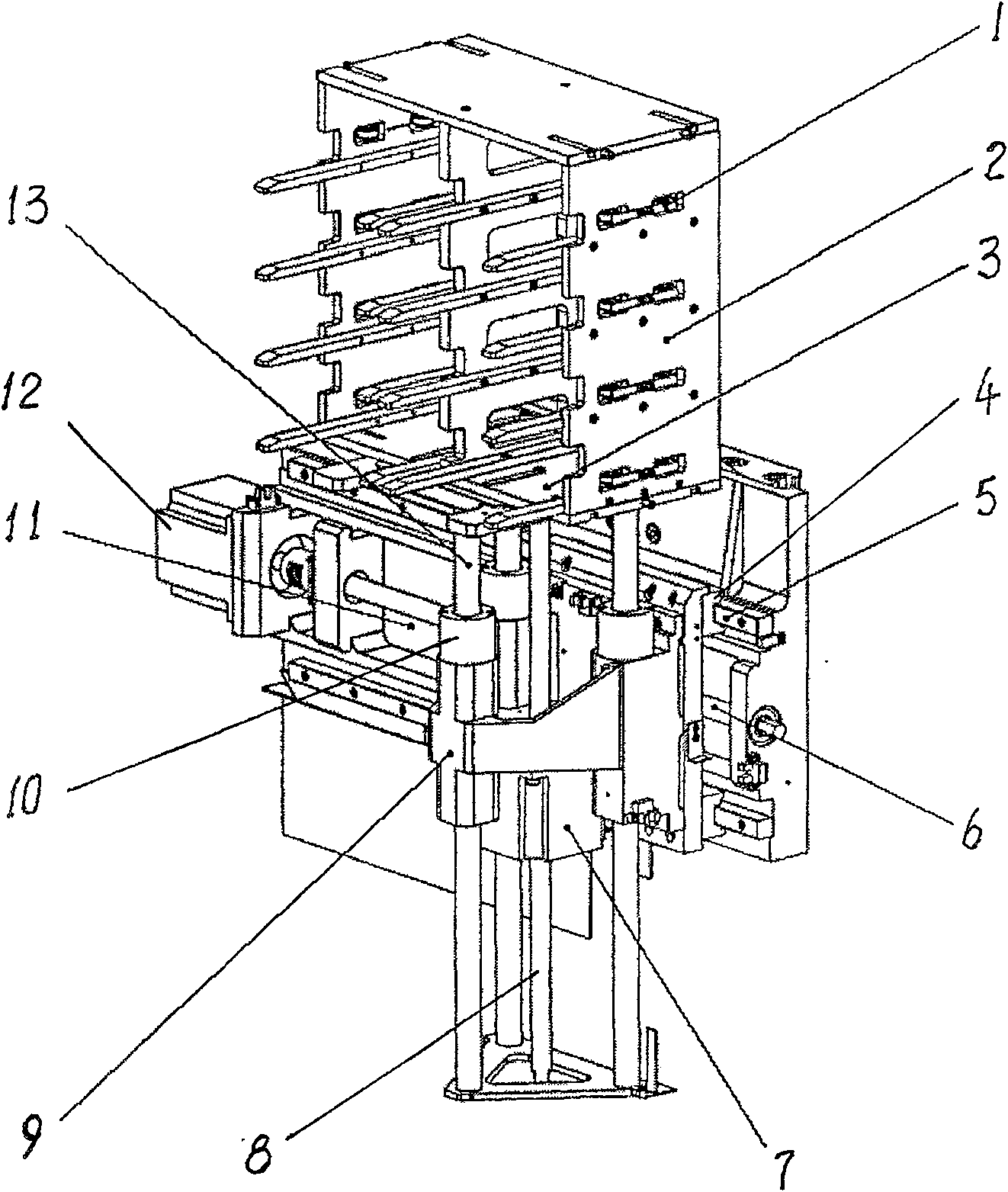

[0012] Referring to the accompanying drawings, the present invention is used for a loading and unloading feeding mechanism on a fully automatic bonding machine. Guide rail 5 is installed on the base 11, and side platform 9 is installed on the slide block 4 that cooperates with guide rail 5, by guide rail slide block, side platform and feeding mechanism can compactly move horizontally. The first stepping motor 12 drives and controls the horizontal movement of the feeding unit 3 through the coupling and the first lead screw 6 . Three guide rods 13 are installed on the side platform 9 to guide the feeding unit. The power output shaft of the second stepper motor 7 is connected with the second lead screw 8 to directly drive and control the up and down movement of the feeding unit 3 . The distance between the feeding unit 3 and the side wall 2 can be adjuste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com