Joint cutter motor

An electromechanical and slitting technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of generating a large amount of exhaust gas, achieve the effect of increasing power density, avoiding the problem of line burning, and reducing mechanical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

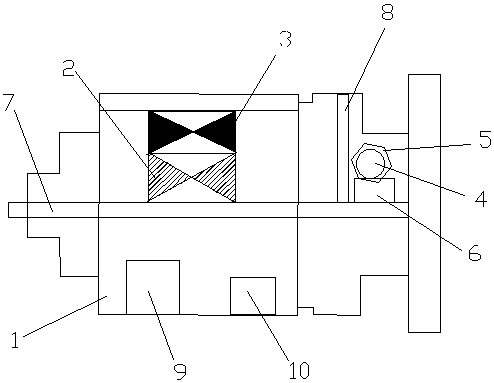

[0018] A sewing machine motor includes a housing 1, a stator 2, a rotor 3, a fan 4, a wind cover 5, and a battery 6. A rotating shaft 7 is arranged in the middle of the housing 1, and the stator 2 is arranged outside the rotor 3. One end of the housing 1 is provided with a partition 8, one side of the partition 8 is provided with the fan 4, and the other side of the partition 8 is provided with the stator 2 and the rotor 3 The wind cover 5 is arranged on the outside of the fan 4, the battery 6 is arranged below the fan 4, and radiating ribs are radially distributed on the outer wall of the housing 1, and the radiating ribs are radially spaced apart The heat dissipation ribs are covered with an outer cover plate, the outer cover plate is provided with a heat dissipation groove and a heat dissipation hole, the heat dissipation groove is provided with a heat dissipation fin, and the heat dissipation fin is arranged in a staggered arrangement with the heat dissipation hole. There i...

Embodiment 2

[0021] A sewing machine motor includes a housing 1, a stator 2, a rotor 3, a fan 4, a wind cover 5, and a battery 6. A rotating shaft 7 is arranged in the middle of the housing 1, and the stator 2 is arranged outside the rotor 3. One end of the housing 1 is provided with a partition 8, one side of the partition 8 is provided with the fan 4, and the other side of the partition 8 is provided with the stator 2 and the rotor 3 , The wind cover 5 is arranged on the outside of the fan 4, the battery 6 is arranged below the fan 4, the outer wall of the housing 1 is radially distributed with radiating ribs, and the radiating ribs are covered with an outer cover plate , The outer cover plate is provided with a heat dissipation groove and a heat dissipation hole, the heat dissipation groove is provided with a heat dissipation fin, and the heat dissipation fin is arranged in a staggered arrangement with the heat dissipation hole.

[0022] The housing is also provided with a cooling circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com