Leveling equipment

A kind of equipment and leveling technology, applied in the direction of artificial level, active optical measurement device, etc., can solve the problems of high manufacturing cost, narrow, no longer sealing effect, etc., and achieve the effect of high rotation speed, high rotation accuracy and high sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

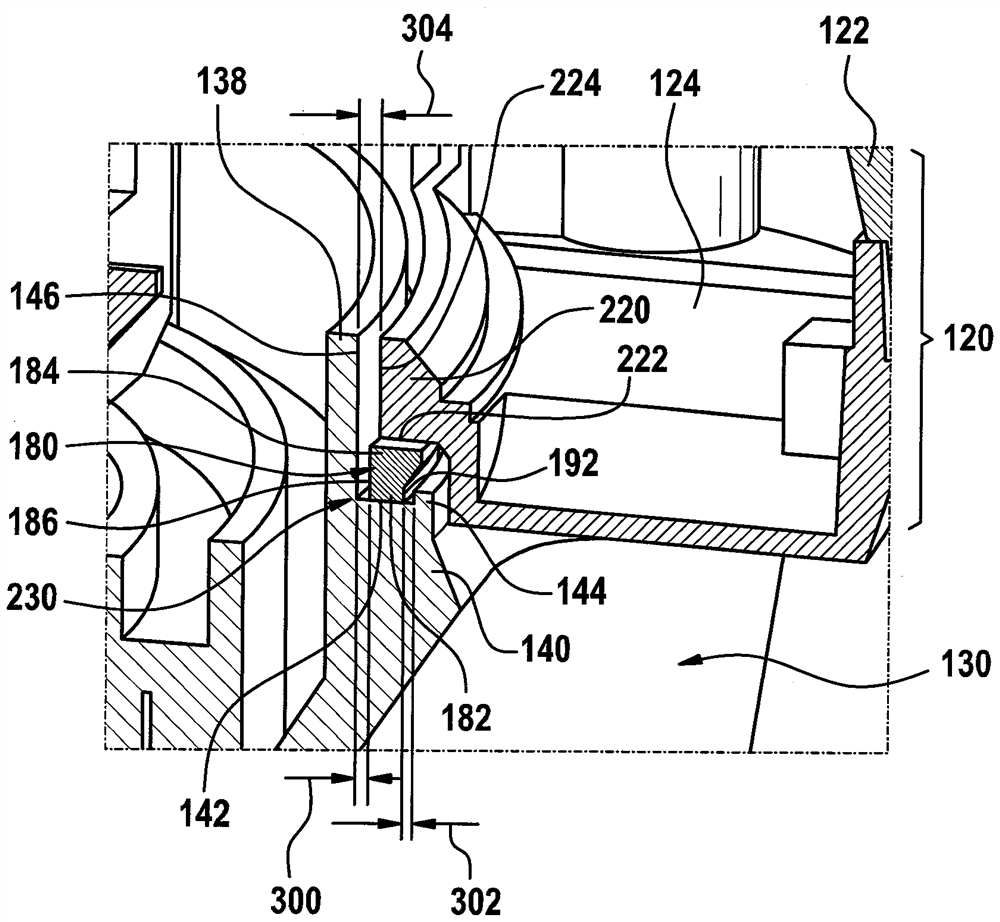

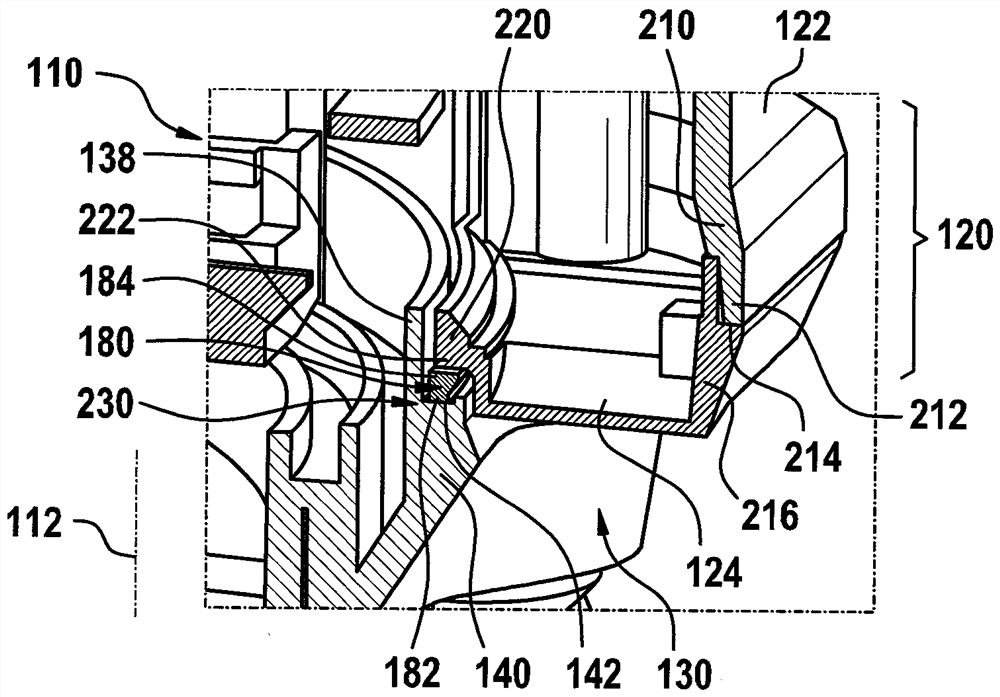

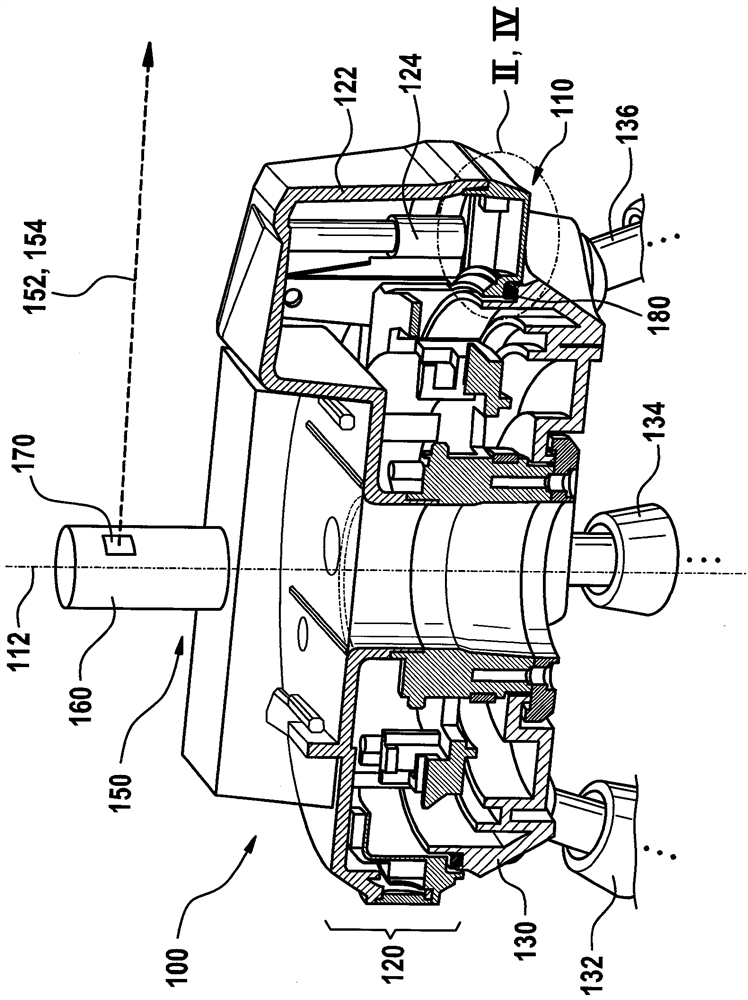

[0031] figure 1 The leveling device 100 is shown with a housing 110 having an upper part 120 and a lower part 130 , wherein the upper part 120 is designed to be freely rotatable relative to the lower part 130 about a longitudinal center axis 112 . The lower part 130 is connected here by way of example to three telescopic support feet 132 , 134 , 136 , by means of which the leveling device 100 rests on a base (not shown). The three telescopic support feet 132 , 134 , 136 are preferably configured in the manner of a tripod or so-called tripod.

[0032] A signal unit 150 for generating an optical signal 152 is preferably arranged on the upper part 120 of the housing 110 of the leveling device 100 . Signal unit 150 can be connected to upper part 120 by the user, preferably without tools, and can be detached again if necessary. The signal unit 150 is preferably designed to emit the optical signal 152 in a self-levelling manner, ie the optical signal 152 is always emitted parallel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com