Workpiece automatic detection equipment

An automatic detection and workpiece technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical gap measurement, etc., can solve the problems of multiple detection items and locations, time-consuming and laborious, complex shapes, etc., and achieve high detection accuracy, convenient use, and improved efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

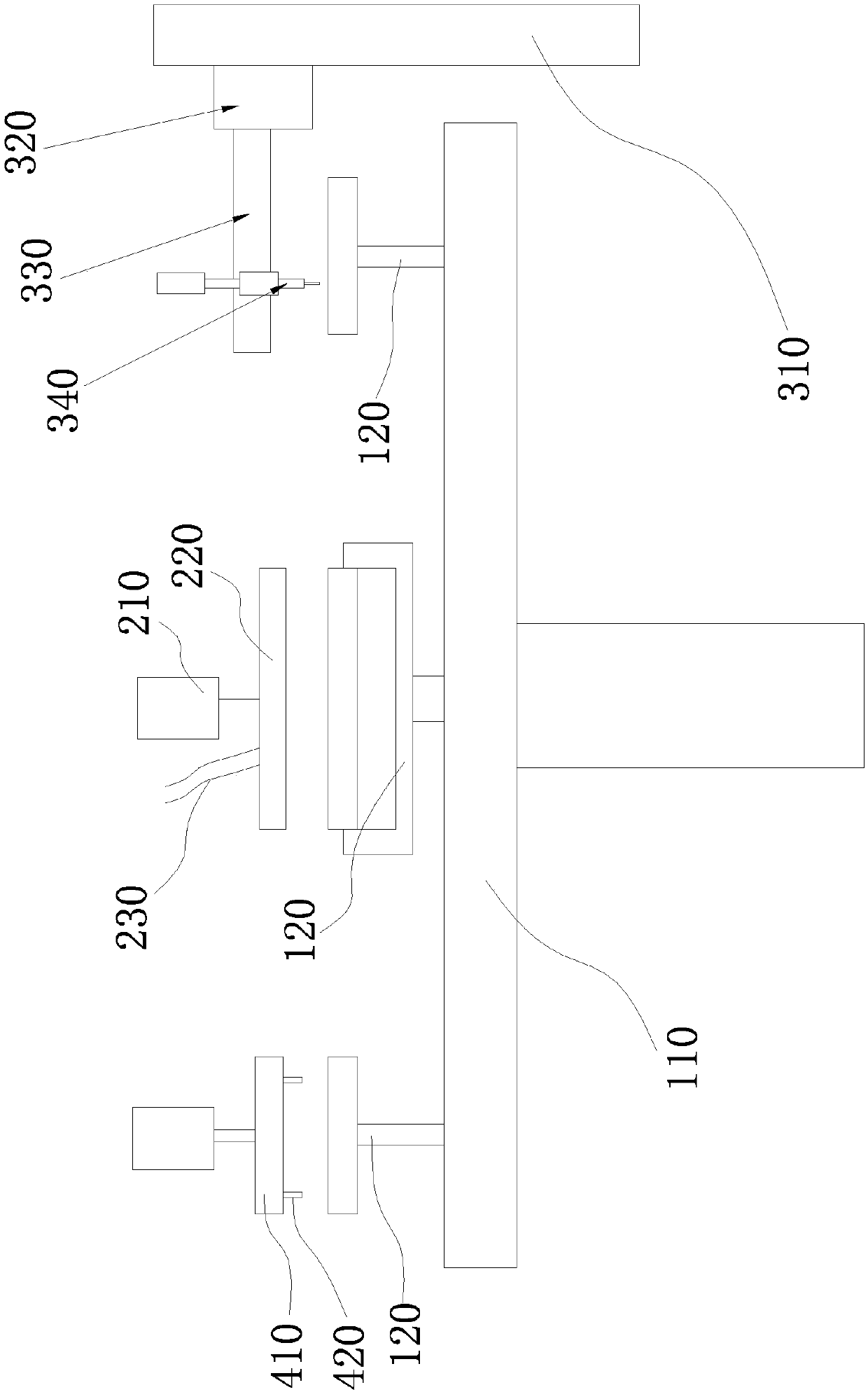

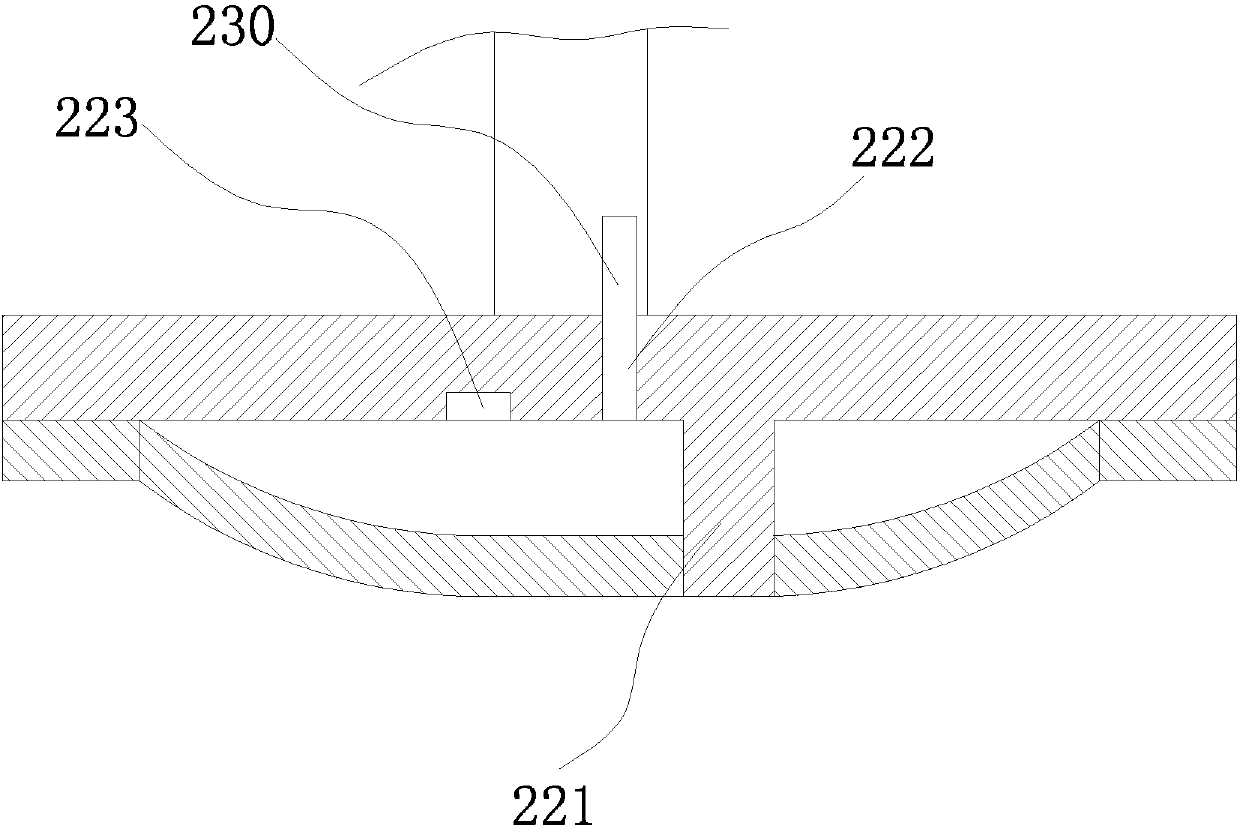

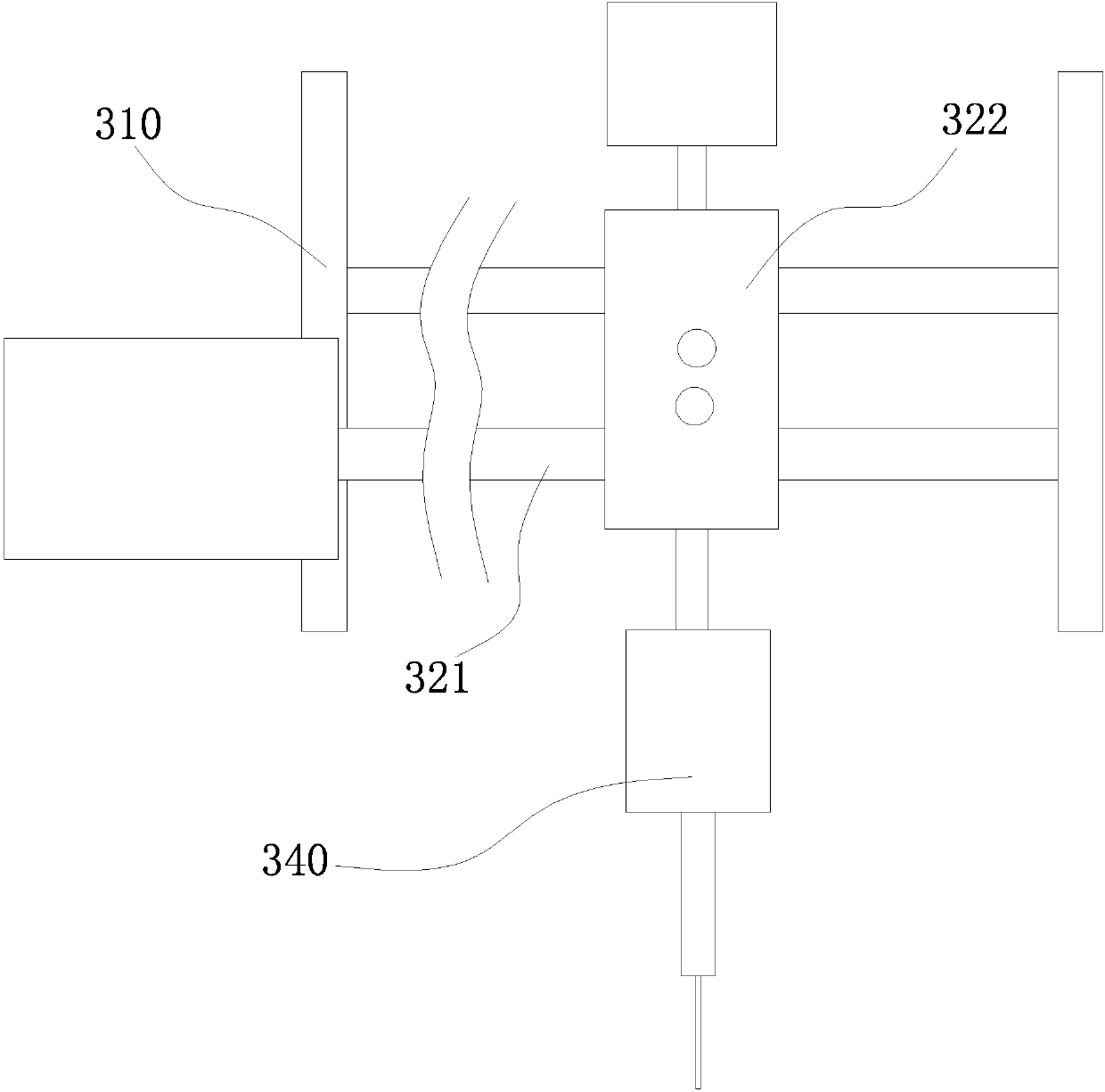

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an automatic workpiece detection device includes: an air tightness detection mechanism, a thread tightness detection mechanism, a threaded hole detection mechanism, and a transmission mechanism. The above automatic workpiece detection device can perform multiple items and different parts of the workpiece. detection, without manpower testing, and no need to replace the jig 120 when changing the test items, thereby improving the accuracy and efficiency of detection.

[0032] Among them, the airtightness detection mechanism is used to detect the airtightness of the workpiece; it is worth noting here that the airtightness of the workpiece refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com