Reversing wheel capable of reducing wire breakage rate

A technology of reversing wheels and disconnection rate, which is applied in the field of solar photovoltaics, can solve problems such as high accident rate, disconnection, and cost increase, and achieve the effect of reducing disconnection rate, avoiding line jamming and disconnection, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0011] The specific implementation of the present invention will be described below in conjunction with the drawings and embodiments:

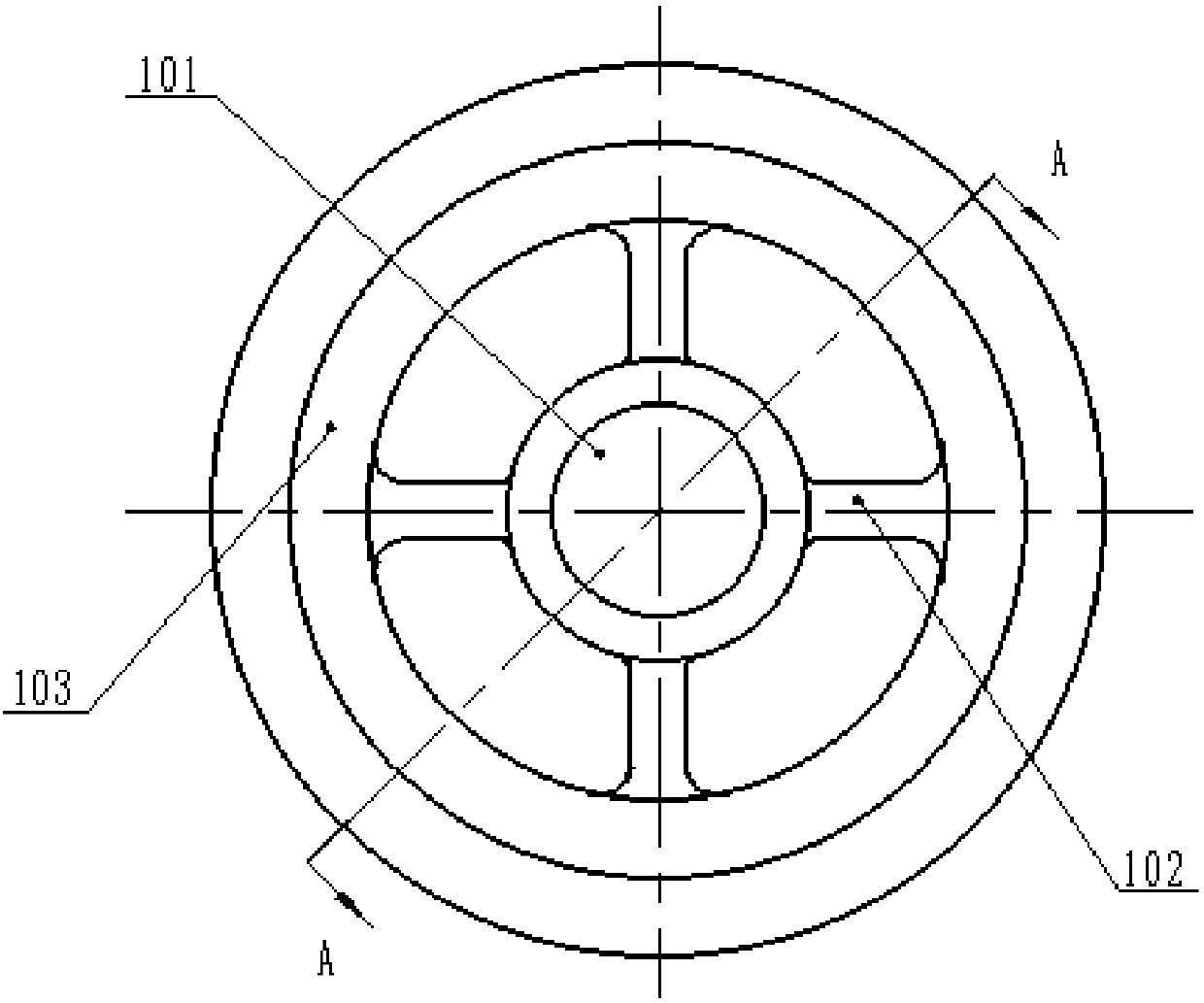

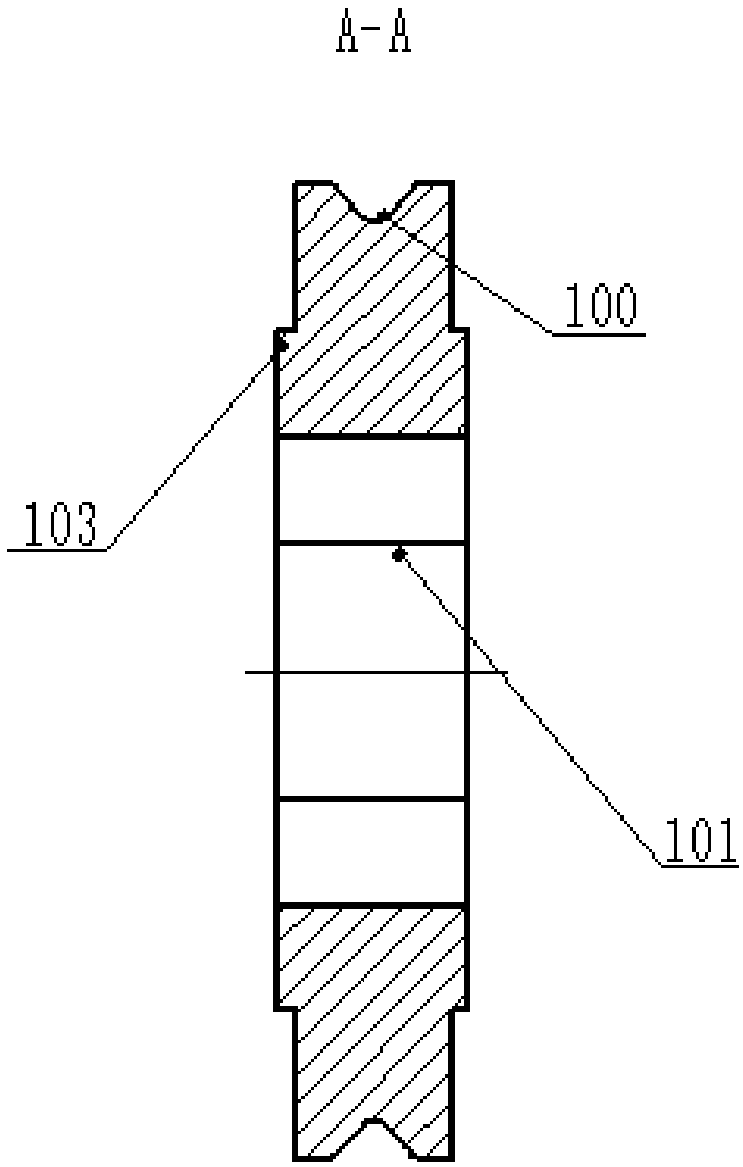

[0012] The main content of the system is: including groove 100, mounting hole 101, spoke 102 and boss 103, characterized in that the reversing wheel is made of diamond wire material, and the neutral surface of the reversing wheel is processed with a circle of concave The groove 100 is a "V"-shaped groove, and the bottom of the "V"-shaped groove is rounded. A mounting hole 101 is machined at the center of the reversing wheel. The mounting hole 101 is a cylindrical hole. There is a boss 103 on the left and right end faces of the reversing wheel. The height of the boss 103 is 5mm. Four evenly distributed spokes 102 are arranged between the outer ring and the inner ring of the reversing wheel. The spokes 102 have a width of 20 mm.

[0013] The reversing wheel is manufactured by casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com