Method for measuring indexes of drill cast-in-place pile slurry

A technology of bored piles and a measuring method, which is applied in the test of basic structure, construction, and basic structure engineering, etc., can solve problems such as complicated operation, and achieve the effects of avoiding complicated operation, improving convenience and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention will be further described.

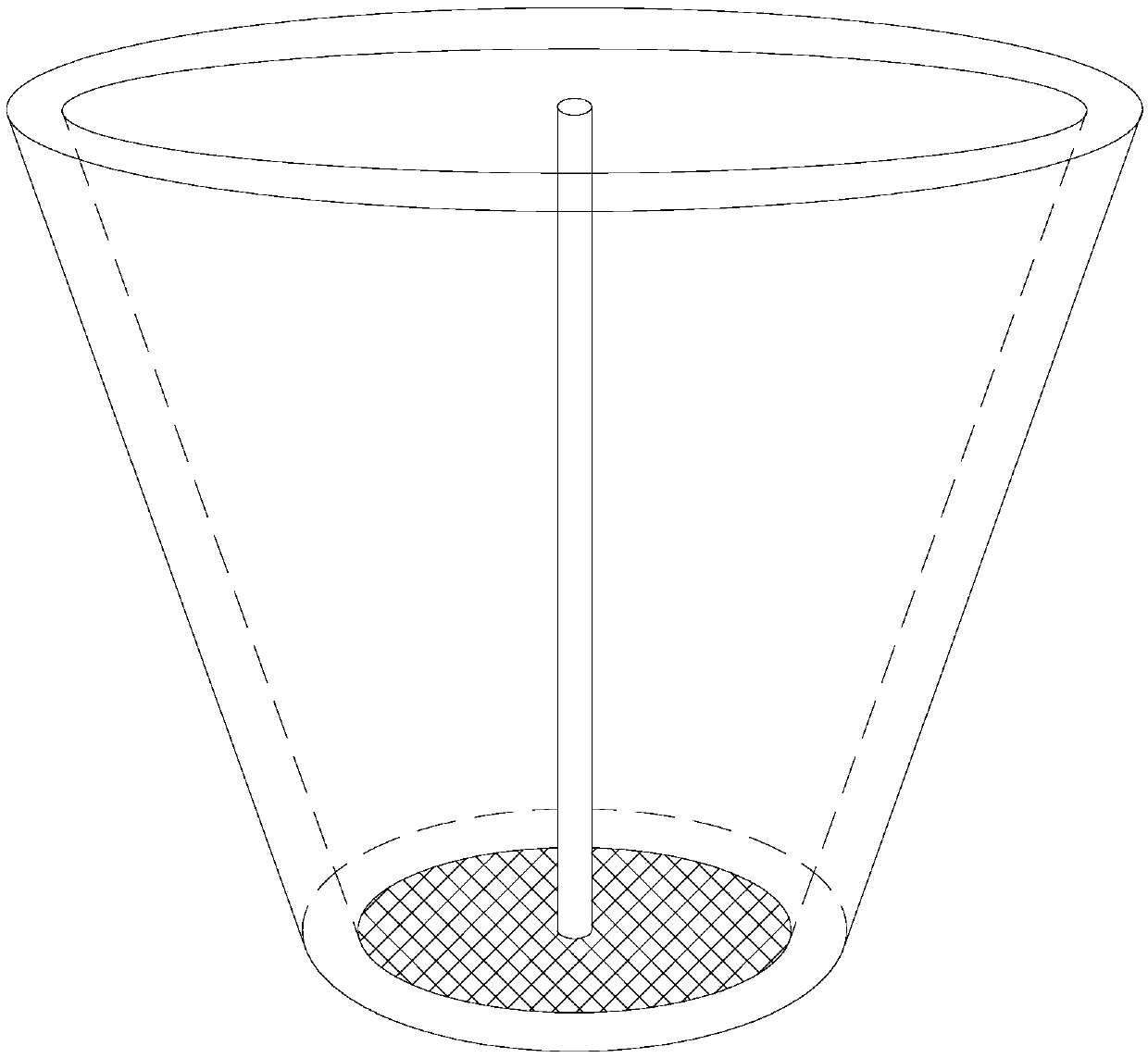

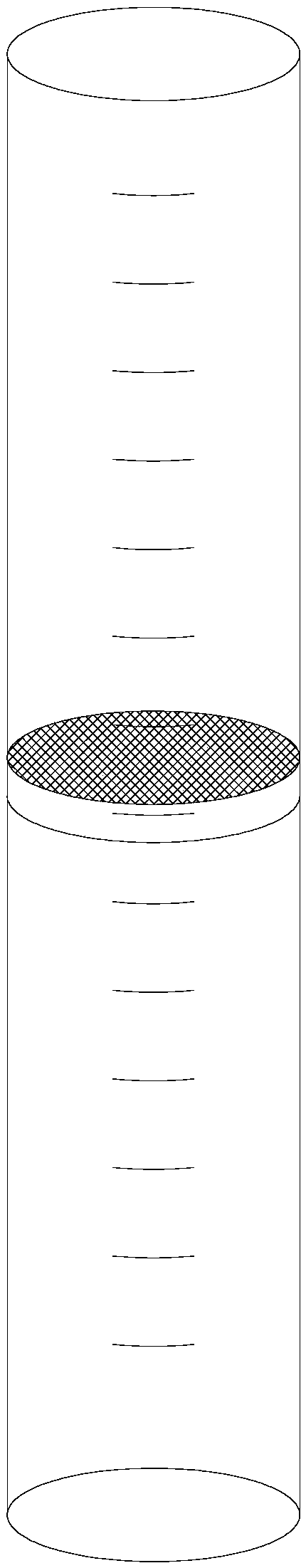

[0017] see as figure 1 , figure 2 As shown, the specific implementation mode adopts the following technical scheme: its various index detection methods:

[0018] a. Relative density of pile-casting mud: It can be measured with a mud relative density meter. Fill the mud cup with the mud to be measured, cover and wash the mud overflowing from the small hole, then place it on the bracket, move the floating code so that the lever is in a horizontal state (that is, the air bubble is in the center), and read the value on the left side of the floating code. The displayed scale is the relative density of the mud;

[0019] b. Viscosity of pile injection mud: Measure 200ml and 500ml of mud with two cups with openings at both ends, filter out large sand particles through a large filter, and pour 700ml of mud into a hollow inverted conical container, and the inverted conical conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com