An automatic packaging waste plastic storage machine

A technology for waste plastics and storage machines, which is applied to presses, manufacturing tools, etc., can solve the problems of easy scattered and scattered in the plastic recycling process, and achieve the effect of convenient centralized storage, convenient transportation, and saving land occupation resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

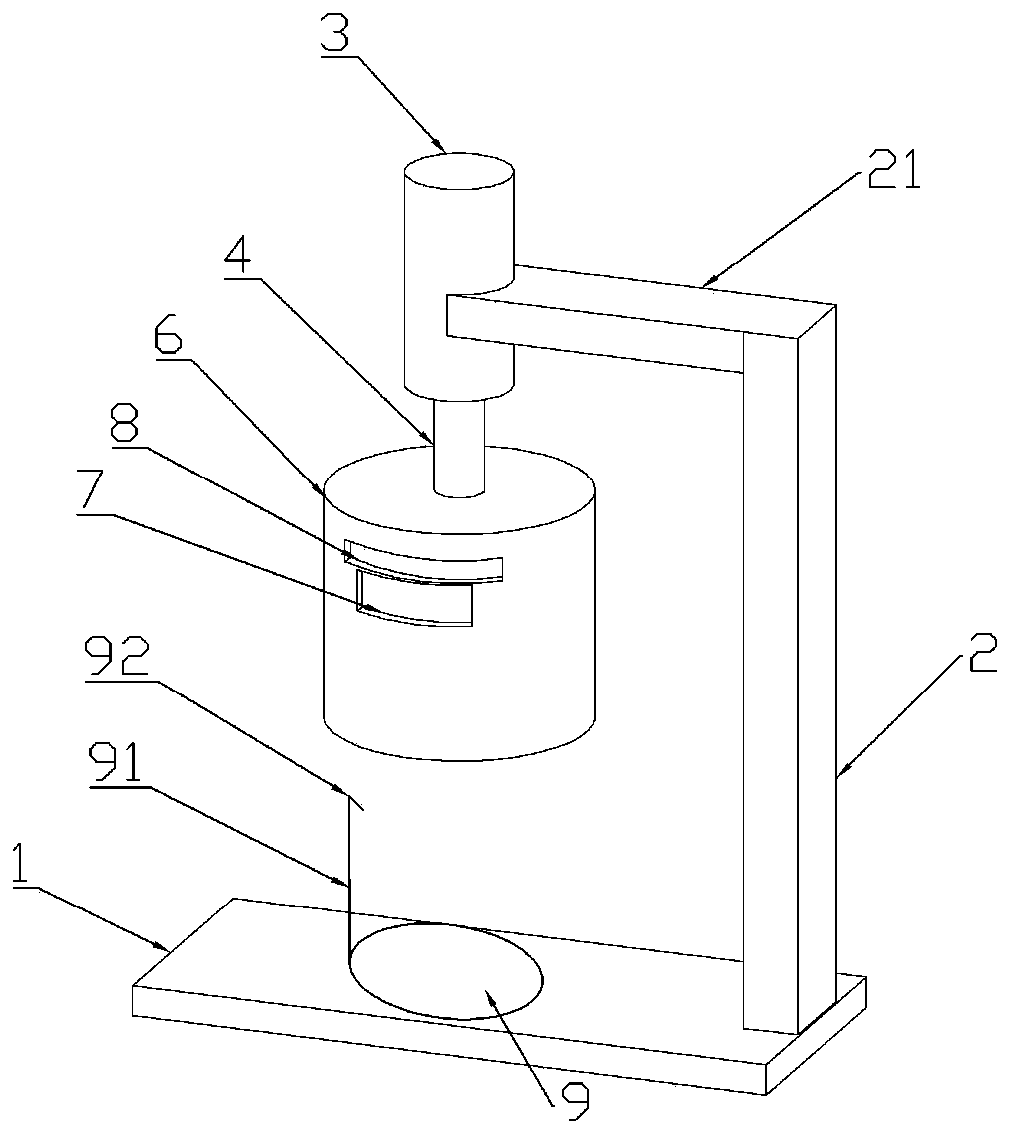

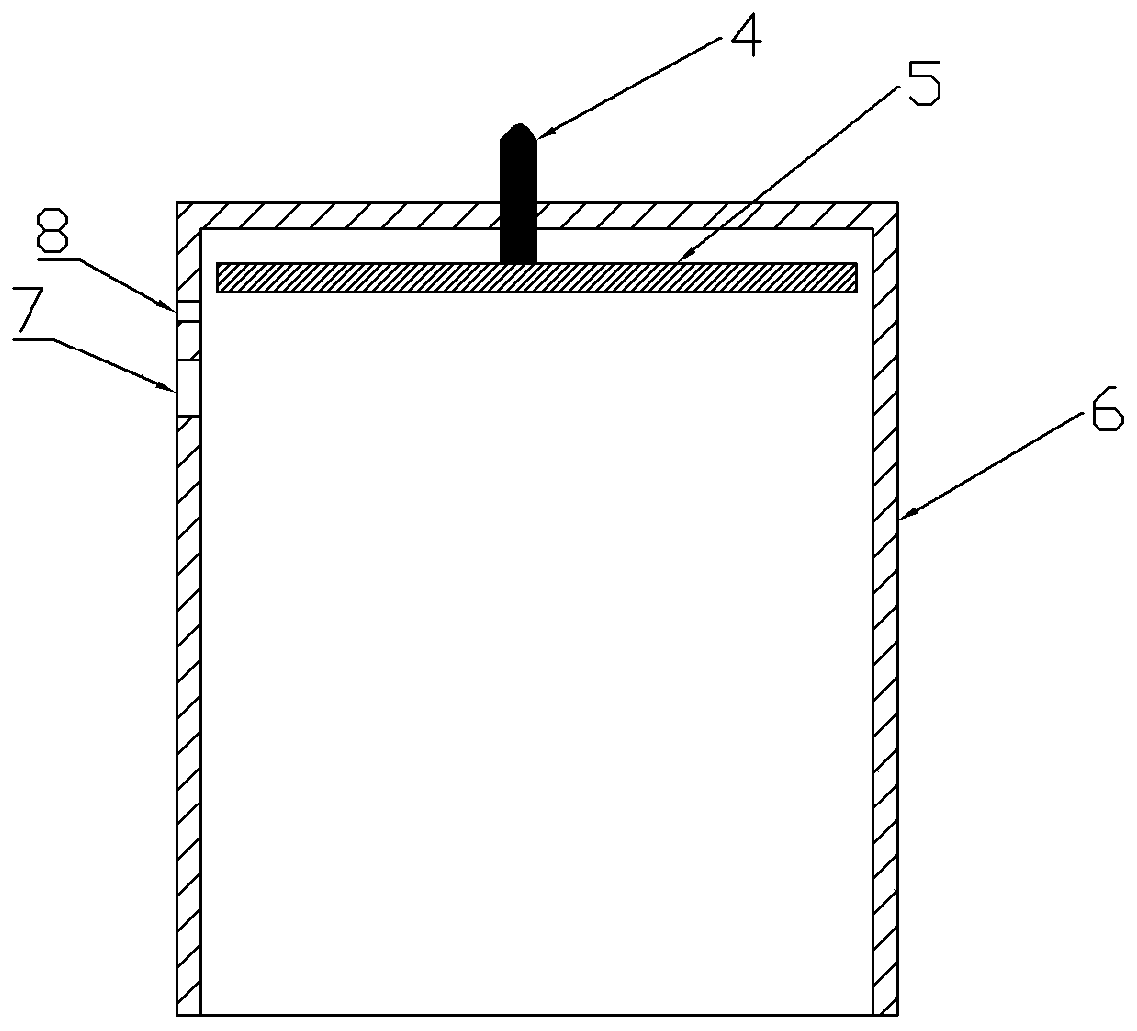

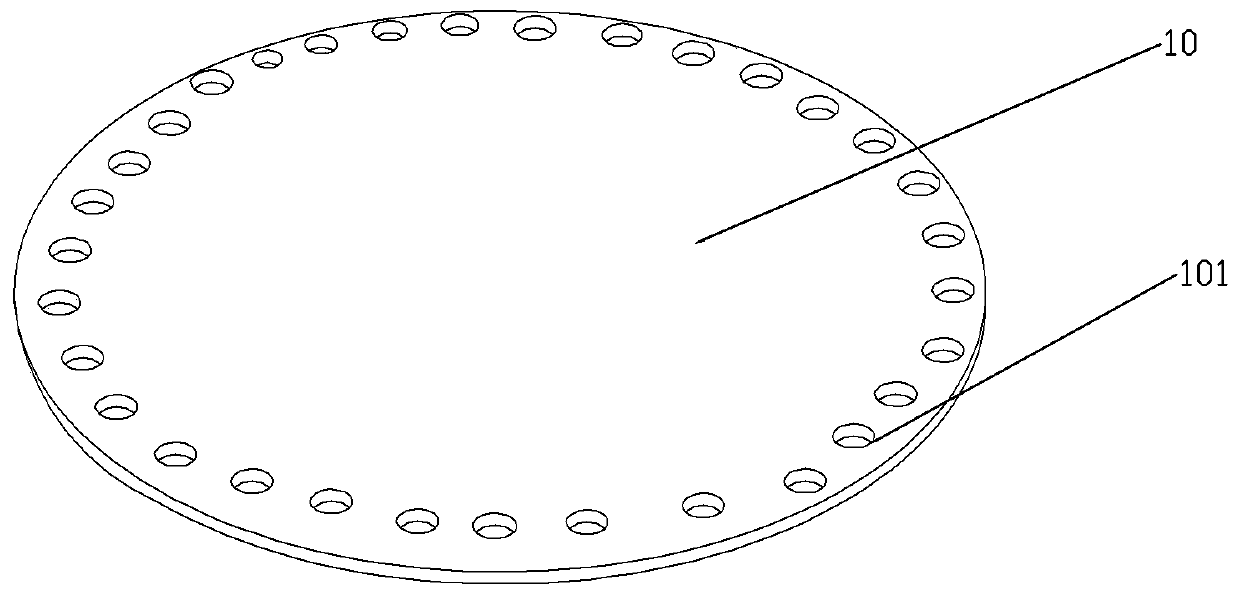

[0029] like figure 1 , figure 2 and image 3 As shown, an automatic packaging waste plastic storage machine of the present invention includes a base 1, a storage cover 10 and a storage bottom 9, a bracket 2 is installed on the base 1, and a beam 21 parallel to the base 1 is installed on the bracket 2, and the beam 21 A hydraulic compression mechanism 3 is installed on the hydraulic compression mechanism 3, and a push rod 4 is installed on the hydraulic compression mechanism 3. A compression plate 5 and a body wall 6 are installed on one end of the push rod 4 far away from the hydraulic compression mechanism 3, and the body wall 6 will press the pressure plate 5 wrapped inside, the body wall 6 is provided with a feed port 7, and a window 8 is provided above the feed port 7, and the storage cover 10 can be placed in the body wall 6 through the window 8, and a through hole is provided on the upper edge of the storage cover 10 101, the edge of the storage bottom 9 is connected ...

Embodiment 2

[0033] like Figure 4 and Figure 5 As shown, on the basis of Embodiment 1, the storage cover 10 and the storage bottom 9 are processed into a hollow shape, which saves materials and reduces its own weight. On the barb rod 91, evenly distributed The relative barb 92 can increase the probability of hooking the barb 92 and the storage cover 10, and four evenly distributed barb rods 91 are arranged on the storage bottom 9, which is convenient for tightly wrapping the compressed waste plastic blocks, and the storage cover 10. The storage bottom 9, the barb rod 91 and the hook are made of plastic material, which is convenient for processing and low in cost, and does not need to be recycled while processing waste plastics.

Embodiment 3

[0035] like Image 6 , Figure 7As shown, on the basis of the second embodiment, the body wall 6 and the pressing plate 5 are arranged in the shape of a cuboid, and at the same time, evenly distributed thorns 11 are set on the pressing surface of the pressing plate 5, and the barb rod 91 can hold the The sealed plastic bottle is punctured, which is convenient for compression. Simultaneously, the protruding thorns 11 can hook the hollow-out storage cover 10, so that the operation steps of placing the storage covers 10 one by one can be omitted during packaging, and the packaging efficiency can be improved; An outwardly extending obliquely upward feed port 7 is installed at the feed port 7. After the loading is completed, the storage cover 10 can be placed on the top of the feed port 7, and the storage cover 10 slides down through the window 8 into the body wall 6 by its own gravity. Inside, the operation step of placing the storage cover 10 in the body wall 6 is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com