Environment-friendly paint spraying equipment

A kind of paint spraying equipment and environment-friendly technology, applied in spraying device, liquid spraying device and other directions, can solve the problems of unguaranteed proportional accuracy, low proportioning accuracy, unable to meet paint spraying, etc., and achieve good spraying effect and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

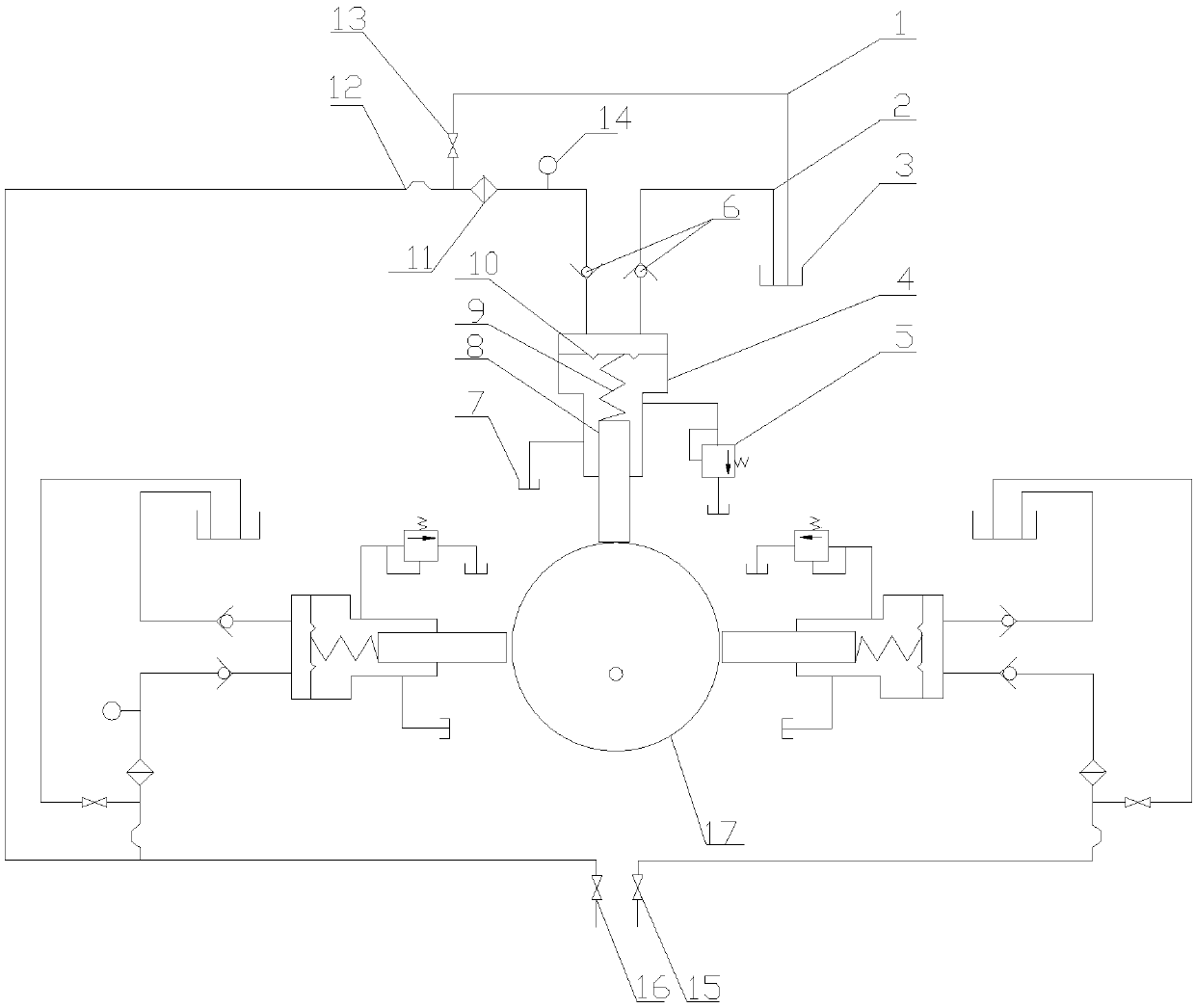

[0018] figure 1 It is a schematic structural diagram of the present invention. As shown in the figure, the environmentally friendly paint spraying equipment of this embodiment includes at least two pumping components for transporting paint, a driving mechanism for driving the pumping components, and a pumping component. Nozzle connected to the material end.

[0019] In this embodiment, the pumping assembly includes a hydraulic pump, a storage tank 3, a suction pipe 2 and a high-pressure pipe 12. The inlet of the hydraulic pump is connected with the storage tank 3 through the suction pipe 2, and the outlet of the hydraulic pump is through the high-pressure pipe 12. Connected with the nozzle, the storage tank 3 is used to store a component liquid in the multi-component coating. The hydraulic pump is used to generate pressure for the liquid coating so that it can be ejected from the nozzle. The nozzle makes the coating instantaneously atomized. Release to the surface of the coated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com