Table tennis bat airing device

The technology of a table tennis racket and ventilation device, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc., can solve the problems of dust easily entering the bonding surface, affecting the quality of the racket, and low drying efficiency. Achieve the effect of reducing dust entry, reducing possibility, and reducing air humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

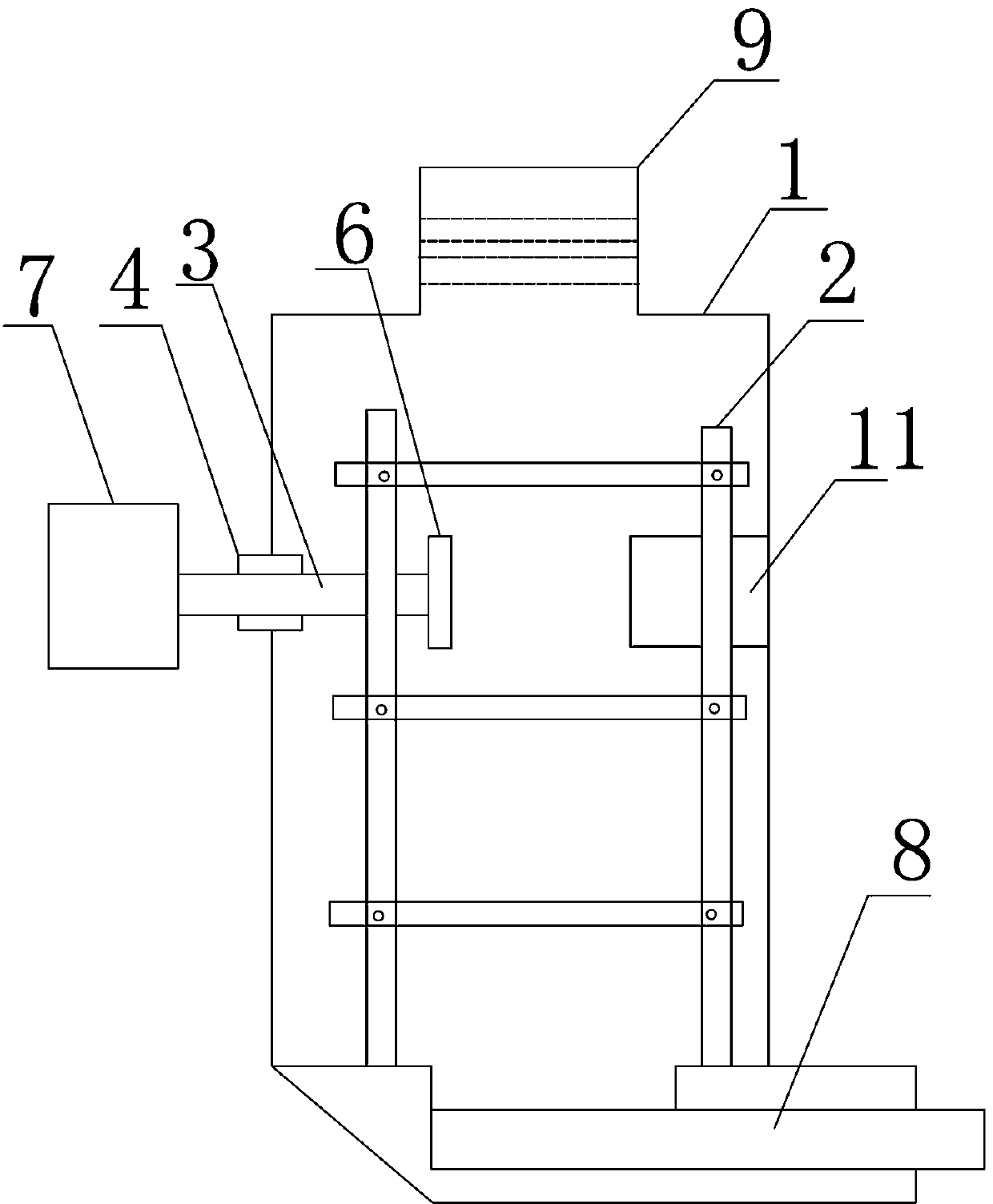

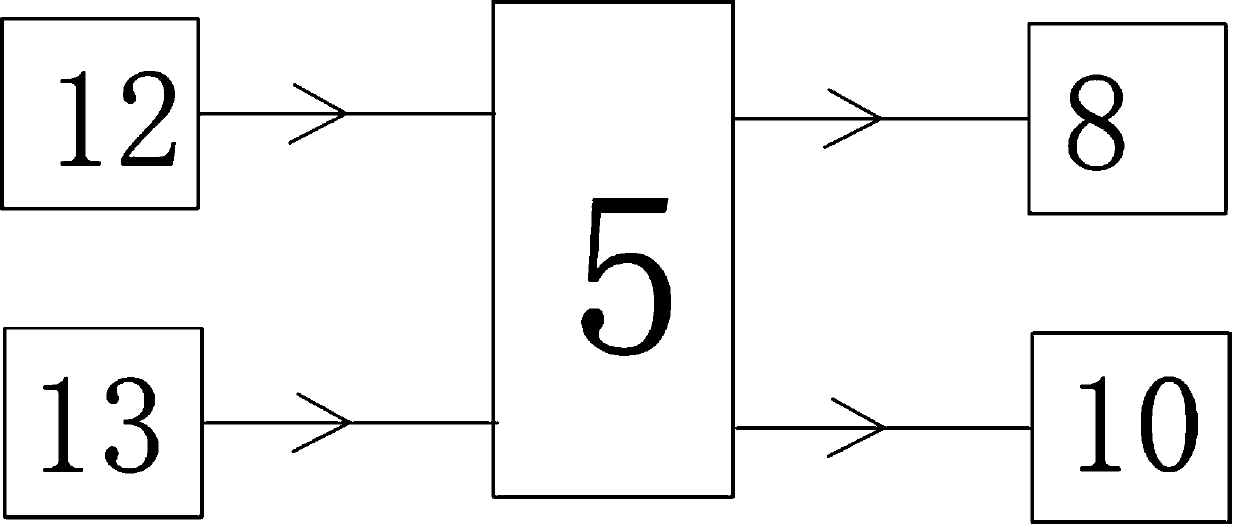

[0012] Such as figure 1 As shown, a table tennis racket drying device includes a fixed frame 2 provided with a sealed box 1, a fixed hole is provided on the fixed frame 2, a compression rod 3 passes through the wall of the sealed box 1 through a sleeve 4, and the compression rod 3 One end of the sealing box 1 is provided with a pressing plate 6, and the end of the pressing rod 3 outside the sealing box 1 is connected with the pneumatic component 7; preferably, a spacer 11 is provided in the sealing box 1 , the extension line of the center line of the compression rod 3 is perpendicular to the spacer 11;

[0013] During work, the racket that needs to be dried is placed in the fixing hole of fixed frame 2, and then the pneumatic part 7 is started to make the pressing rod 3 drive the pressing plate 6 to press the racket that needs to be dried. The reverse thrust of the pressed racket, so that the thrust of the pressing plate 6 to the racket is all applied to the bonding surface b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com